Mining and driving method combined splitter with hydraulic breaking hammer

A technology of hydraulic breaker and splitter, which is applied in special mining, discharge machinery, earth drilling and mining, etc. It can solve problems such as inability to directly load vehicles, surrounding environmental pollution, dust flying, etc., and achieves wide application range, environmental protection, The effect of a good construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

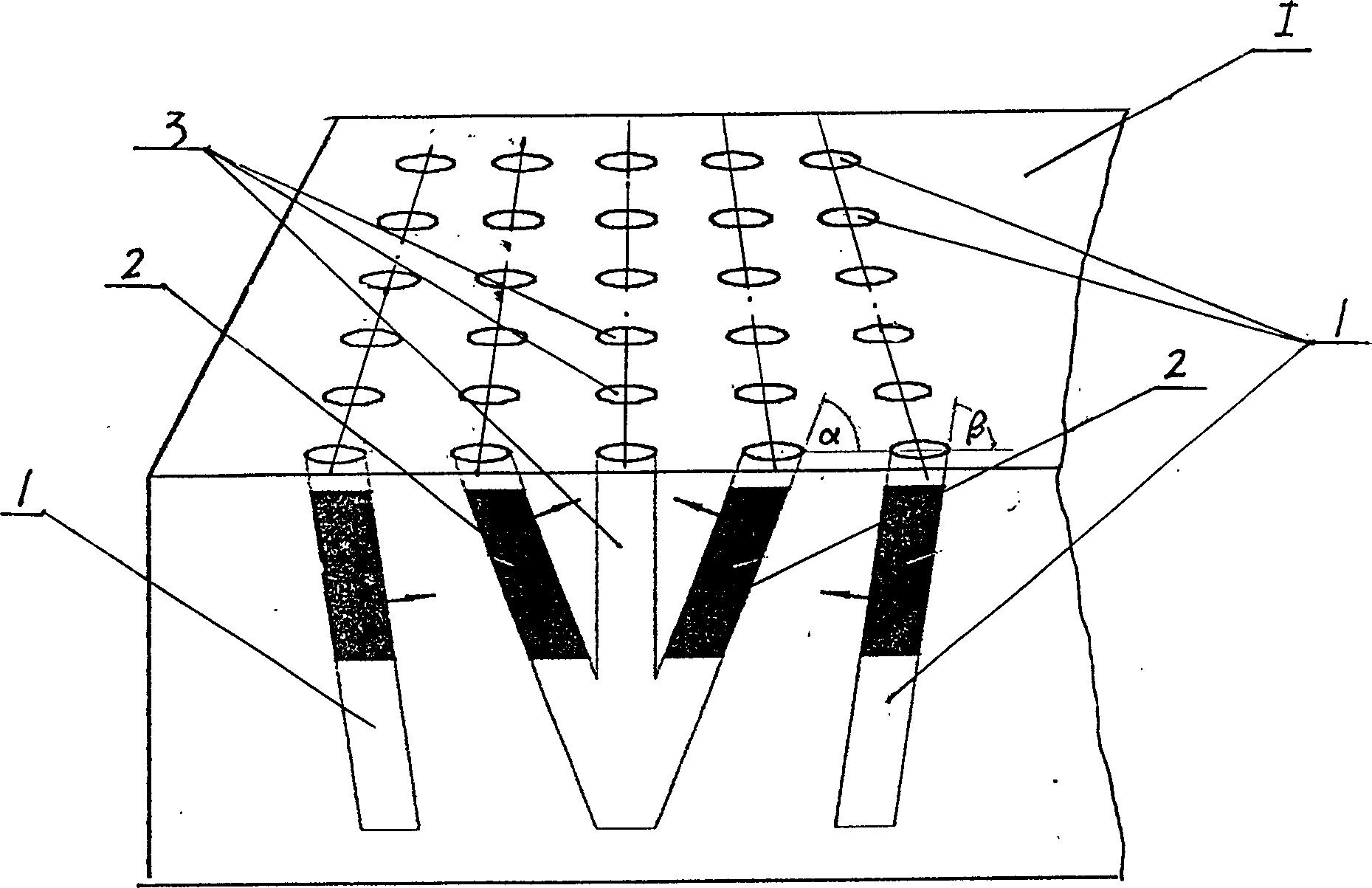

[0022] In a joint mining test in a mine, on the horizontal working face of the rock ore body, a drilling machine was used to drill 5 rows of 25 holes in total, including 5 cut holes in the middle, and the inner split holes on the left and right sides respectively. 5, 5 outer split holes on the left and right sides respectively, the measured hole depths are 805mm, 860mm and 998mm, the hole diameters are 70mm, 125mm and 200mm, the hole distance is 800mm, the center of each left inner split hole The angle between the line and the rock plane is 30°, the angle between the center line of each right inner split hole and the rock plane is 45°, and the angle between the center line of each left outer split hole and the rock plane is 50° °, the angle between the center line of the outer split hole on the right side and the rock plane is 80°, and a splitter is placed in each inner and outer split hole, and the plungers of the splitter are all pointed to the cut hole, and then the Through...

Embodiment 2

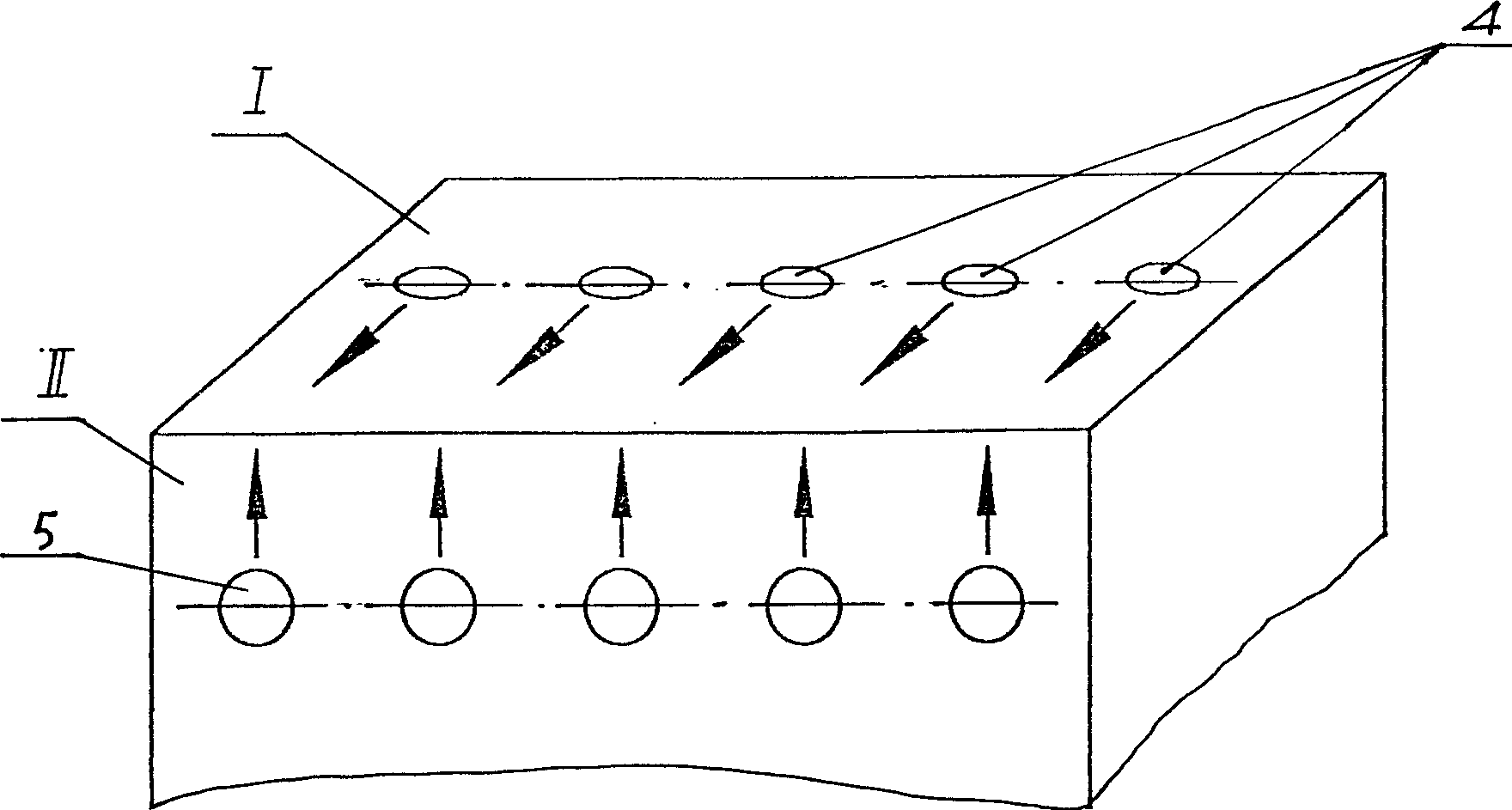

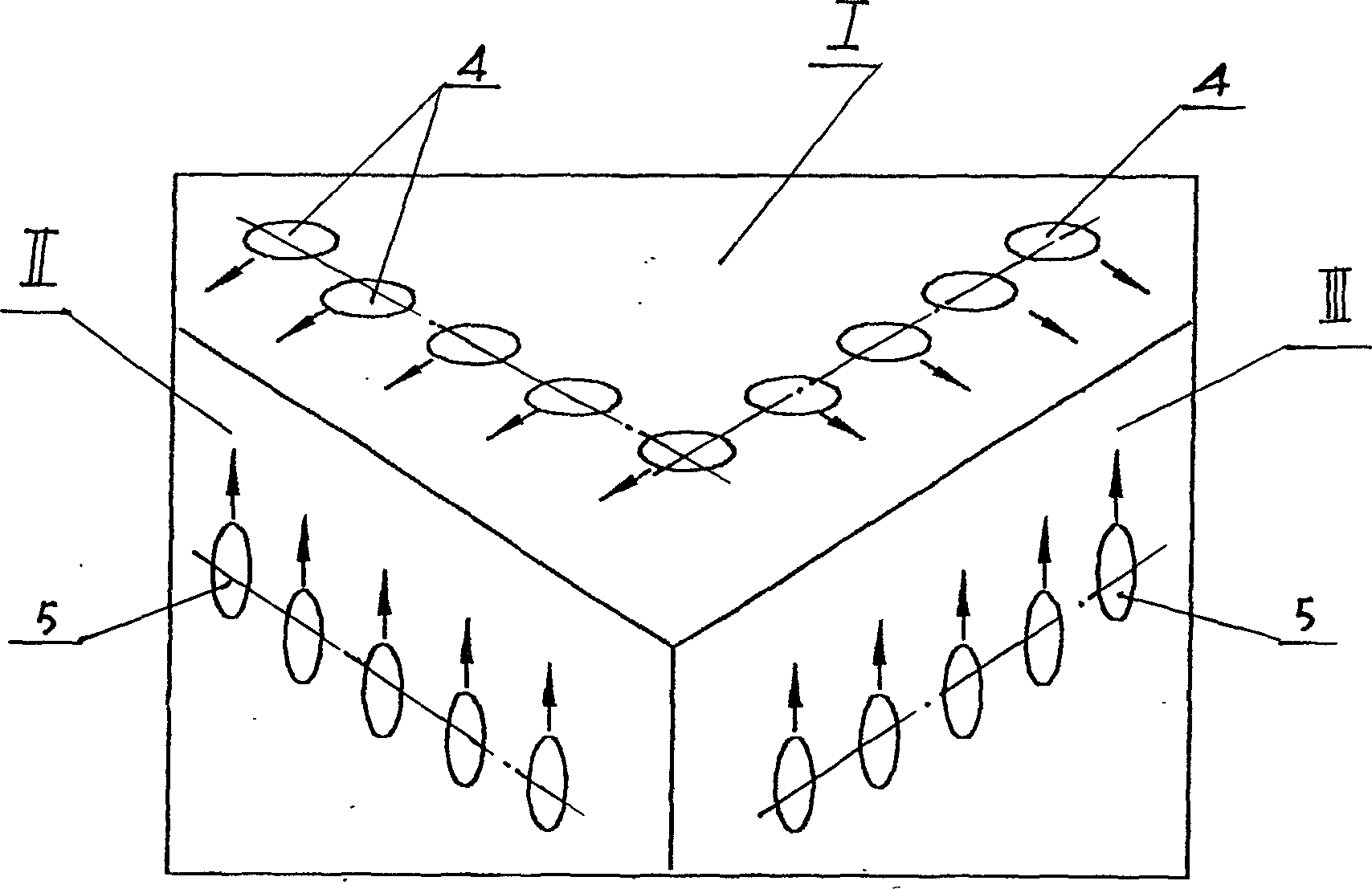

[0024] In a joint mining test in a mine, on a vertical working surface with a horizontal working surface and two adjacent vertical working surfaces that are approximately at right angles to each other, first use a drilling machine to drill a right-angled hole on the horizontal working surface with a depth of 805mm. , the hole diameter is 120mm, the hole distance is 800mm and the hole depth is 1000mm, the hole diameter is 65mm, and the hole distance is 800mm. There are 5 horizontal holes with a drilling depth of 810mm, a hole diameter of 70mm, 105mm, and 200mm, and a hole spacing of 800mm. A splitter is placed in each vertical hole and horizontal hole, and the splitter placed in the vertical hole The plunger points to the corresponding vertical working surface, the plunger of the splitter placed in the horizontal hole points to the corresponding horizontal working surface, the peripheral oil source is connected, each splitter works, and the rock mass is split within 4-5 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com