Electrophotographic photoconductor for wet developing and image-forming apparatus for wet developing

A technology of electrophotography and photoreceptor, applied in the direction of developer, optics, electrography, etc., can solve the problem of being easily soaked, and achieve the effect of improving solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0212] (1) Preparation of electrophotographic photoreceptor for wet development

[0213] In the ultrasonic disperser, 4 parts by weight of X-type metal-free phthalocyanine (CGM-1), which is one of the compounds represented by formula (3), as a charge generating agent; 19) 40 parts by weight of a diphenylvinylamine compound (HTM-1) as one of the compounds represented; 40 parts by weight of a naphthoquinone derivative (ETM-1) as one of the compounds represented by the formula (8) as an electron transport agent Parts by weight; 100 parts by weight of a polycarbonate resin (Resin-1) with a viscosity average molecular weight of 50,000 represented by the following formula (20); as a leveling agent, dimethyl silicone oil KF-96- 50CS (manufactured by Shin-Etsu Chemical Industry) 0.1 parts by weight; 750 parts by weight of tetrahydrofuran as a solvent. Then, it was mixed and dispersed by ultrasonic treatment for 60 minutes to prepare a coating liquid.

[0214] The obtained coating solution...

Embodiment 2~10 and comparative example 1~3

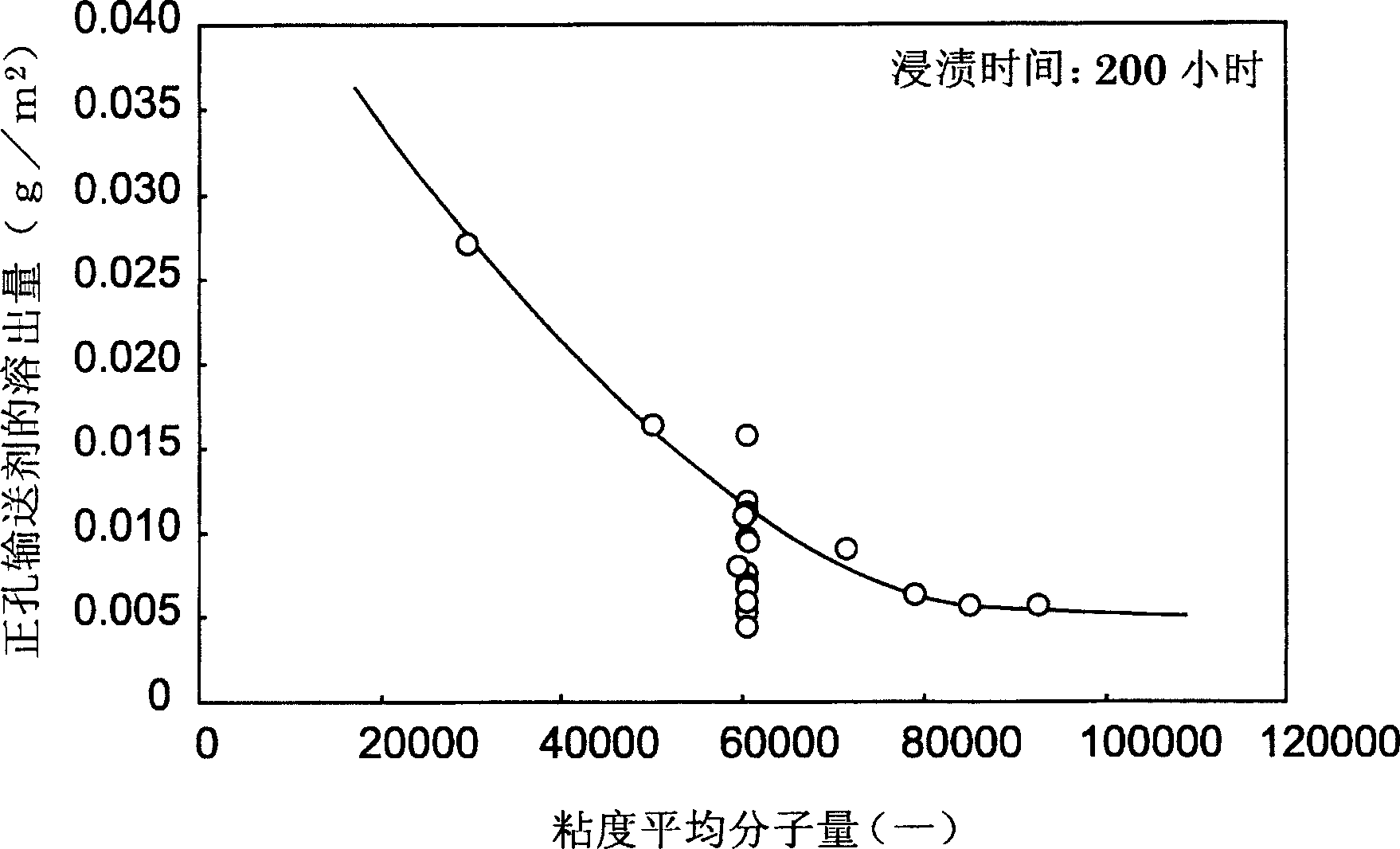

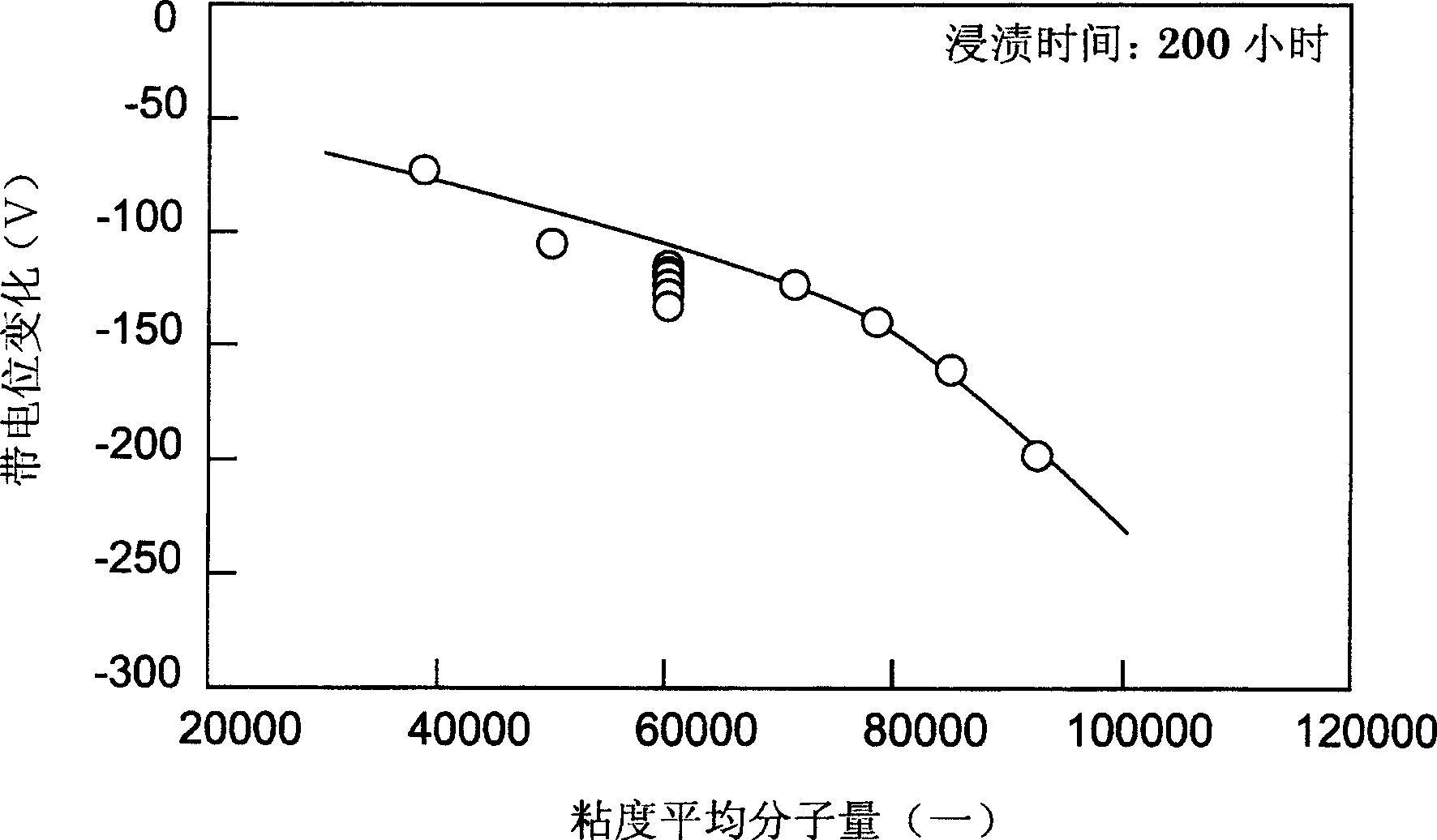

[0239] In Examples 2 to 10, the positive hole transport agent represented by the formula (19) shown in Table 1, the electron transport agent represented by the formula (8), and the electron transport agent represented by the following formula (23) were used, respectively. Except for the binder resin, in the same manner as in Example 1, a single-layer type electrophotographic photoreceptor for wet development was prepared and evaluated.

[0240] In addition, in Comparative Examples 1 to 3, in addition to the amine compound (HTM-36) represented by the following relational formula (21), the electron transport agent (ETM-10 and 11) represented by the following relational formula (22), Except for the binder resins (Resin-2 to 5) represented by the following relational expression (23), in the same manner as in Example 1, a single-layer type electrophotographic photoreceptor for wet development was prepared and evaluated. In addition, the viscosity average molecular weights of the binder...

Embodiment 11~22

[0252] In Examples 11-22, the single-layer electrophotographic photoreceptors for wet development obtained in Examples 1 to 4 were used instead of the isoparaffin solvent L used as the developer for wet development, and isoparaffin solvent G was used respectively. , Isoparaffin solvent H, Norpar12, respectively evaluated the above-mentioned solvent resistance test and sensitivity change. The results obtained are shown in Table 3, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com