Pug fired cinerary box

A technology for cremation urns and mud materials is applied in the field of funeral urns, funeral supplies, and mud material burning urns. Simple, easy-to-follow effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

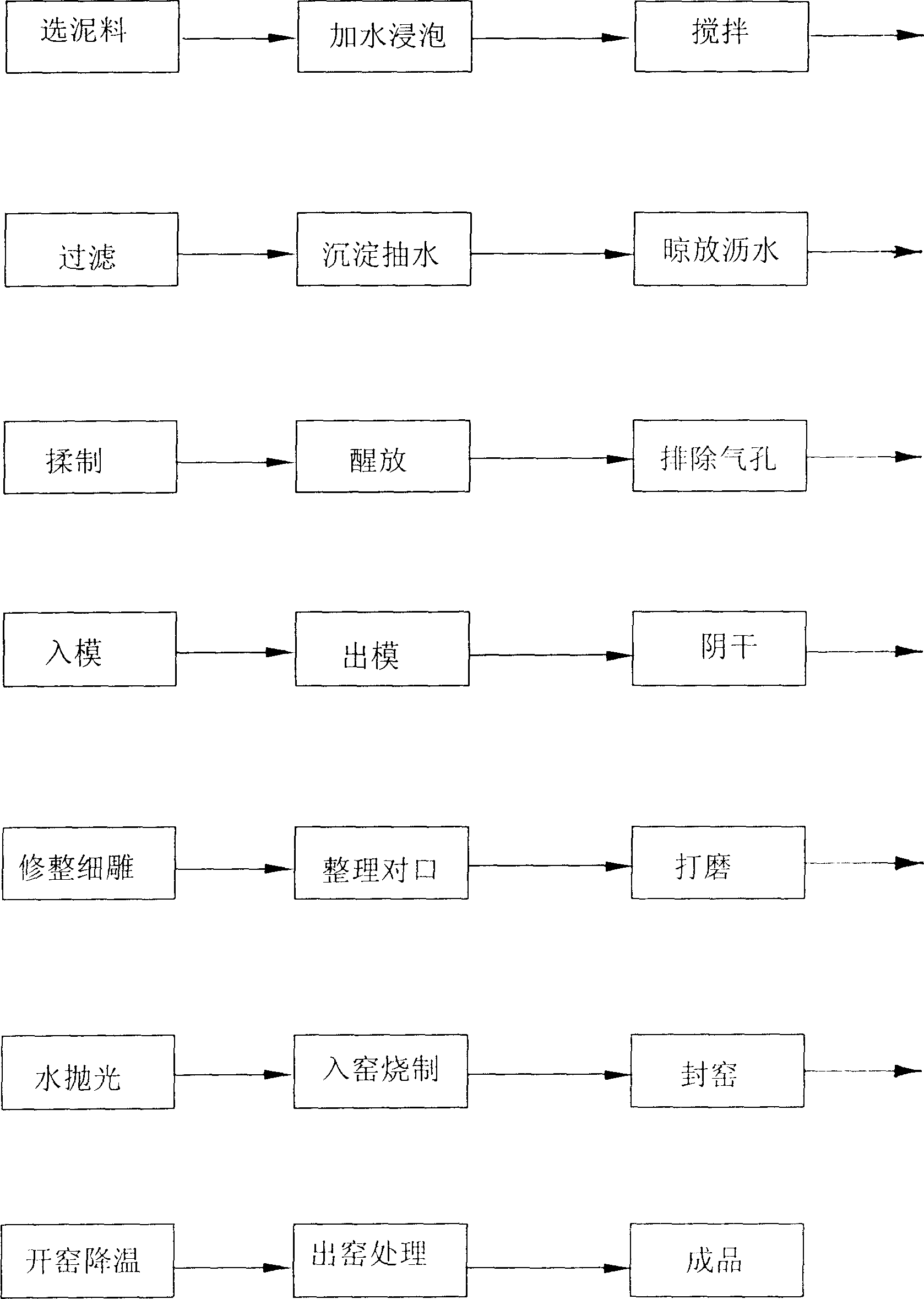

Method used

Image

Examples

specific Embodiment approach 2

[0074] Carry out by specific embodiment one, just in concrete implementation process: the sand content of mud material is 5.5%, and the water temperature in adding water soaking is 20 ℃, the time of static immersion is 4 days, and the water temperature of stirring is 20 ℃, Stir in a counterclockwise direction and at a speed of once every two seconds. The temperature for airing and draining is 20°C, the time for airing and draining is 6 days, and the temperature for waking up is 20°C. Cut into 1.25 cm thick mud pieces, exhaust and eliminate pores by vacuuming with vacuum equipment, dry in the shade at 25°C for 5 days, the first day of firing in the kiln at 150°C, the second The temperature on the second day is 350°C, the temperature on the third day is 550°C, the temperature on the fourth day is 750°C, and the temperature on the fifth day is 950°C. The temperature inside dropped to 50°C. Good results were obtained as expected.

specific Embodiment approach 3

[0075] Carry out by specific embodiment one, just in concrete implementation process: the sand content of mud material is 8%, and the water temperature in adding water soaking is 30 ℃, the time of static immersion is 5 days, and the water temperature of stirring is 30 ℃, Stir in one direction horizontally, at a speed of once every 3 seconds. The temperature for airing and draining is 25°C, the time for airing and draining is 8 days, and the temperature for waking up is 25°C. The final mud is cut into 1.5 cm thick mud pieces, exhausted and eliminated pores by means of vacuuming equipment. The temperature of drying in the shade is 30°C for 6 days, and the temperature on the first day of firing in the kiln is 200°C. °C, the second day temperature is 400 °C, the third day temperature is 600 °C, the fourth day temperature is 800 °C, the fifth day temperature is 1000 °C, the time for closing the kiln is 5 days, and the time for opening the kiln to cool down is 3 days , The temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com