Permanent magnet biased external rotor radial magnetic bearing

A permanent magnetic bias, external rotor technology, applied in the direction of magnetic bearings, bearings, shafts and bearings, etc., can solve the problems of large excitation current, increased bearing power consumption, long axial length, etc., to reduce copper consumption and control power amplifiers Effects of loss, elimination of bias current, and reduction of axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

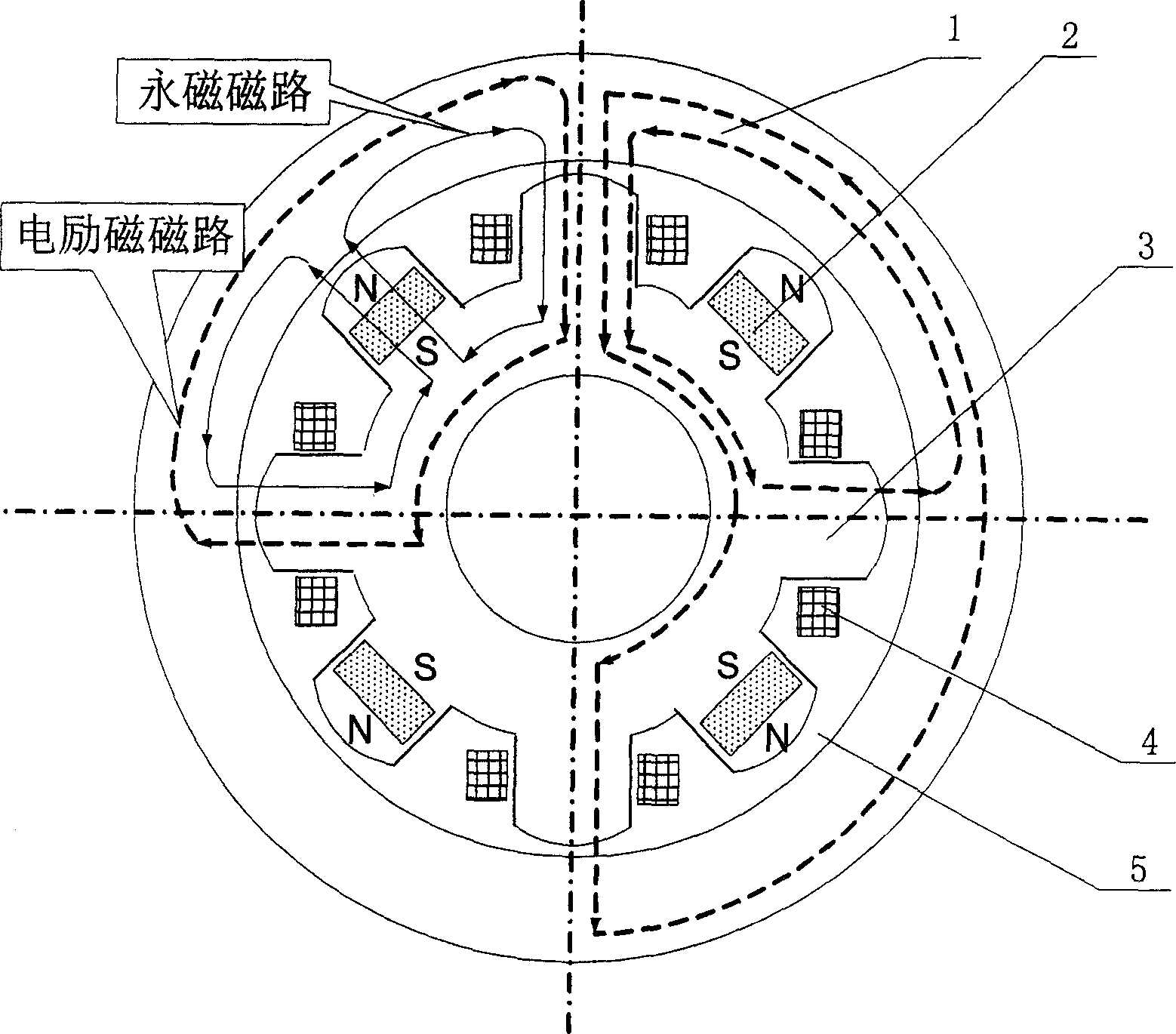

[0008] like figure 1 As shown, the present invention is composed of a rotor core 1, a permanent magnet 2, a stator core 3, and an excitation coil 4. The magnetic poles of 8 stator cores 3 are evenly distributed on the circumference of the magnetic bearing, and 4 permanent magnets 2 are embedded in the stator core at intervals. Among the four magnetic poles of 3, that is, the two sides of the stator core pole embedded with the permanent magnet 2 are the stator core poles not embedded with the permanent magnet 2. And the four magnetic poles of the stator core 3 not embedded in the permanent magnet 2 are distributed along +X, -X, +Y and -Y, and are surrounded by exciting coils. For the convenience of processing and installation, and considering the factor of magnetic saturation, the distance between the two ends of the stator core 3 and the two ends of the permanent magnet 2 embedded in it is about 0.5mm; there is a certain gap between the outer surface of the stator core 3 and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap