Transpositional method for partial defective print circuit module in print circuit board

A technology of printed circuit boards and printed circuits, which is applied in the direction of printed circuits, printed circuit manufacturing, and assembly of printed circuits with electrical components, which can solve the problems of rising production costs of finished substrates, poor connection stability, cumbersome operations, etc., and achieve rapid replacement, Effect of reducing waste and simplifying the replacement procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

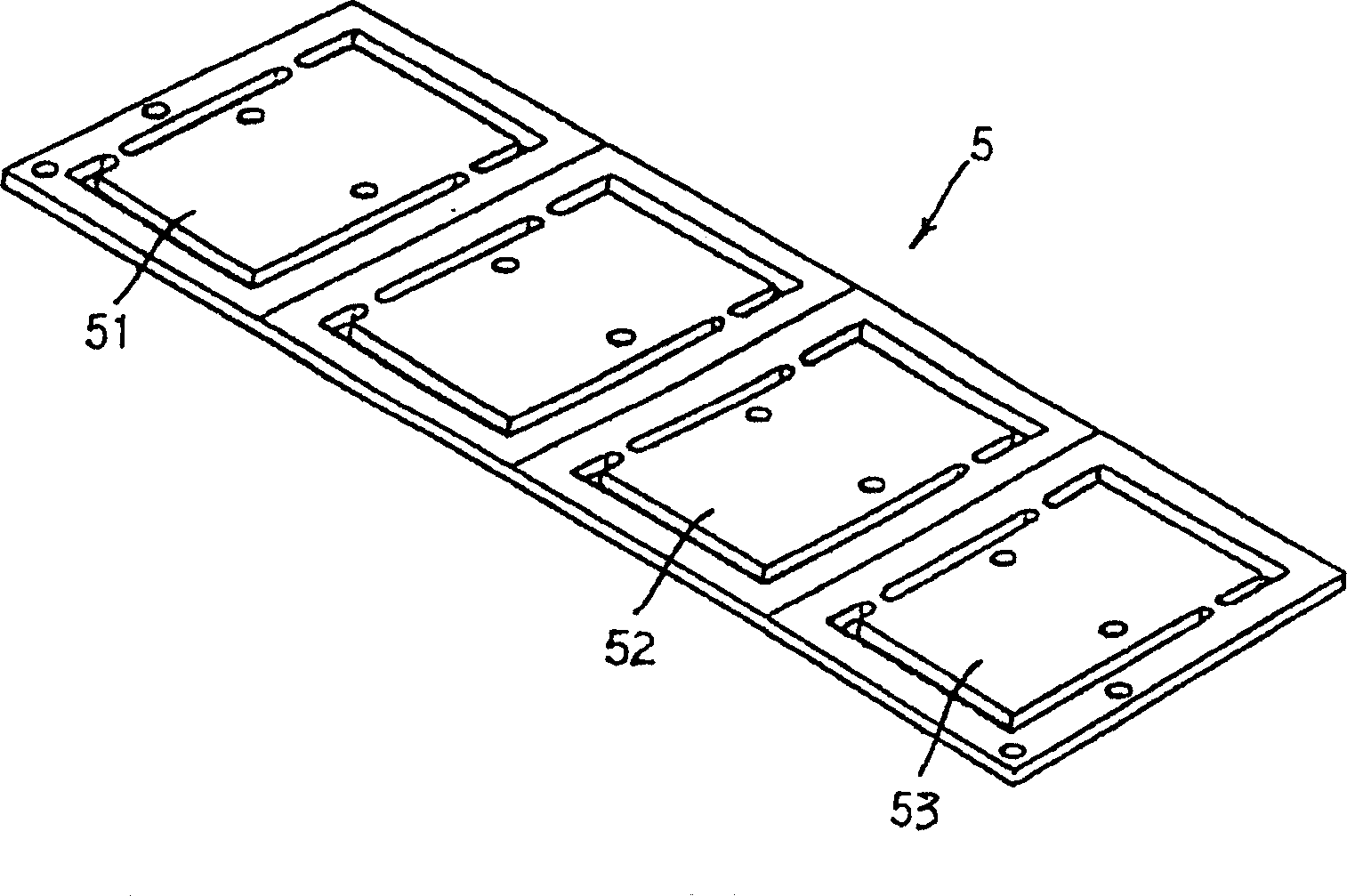

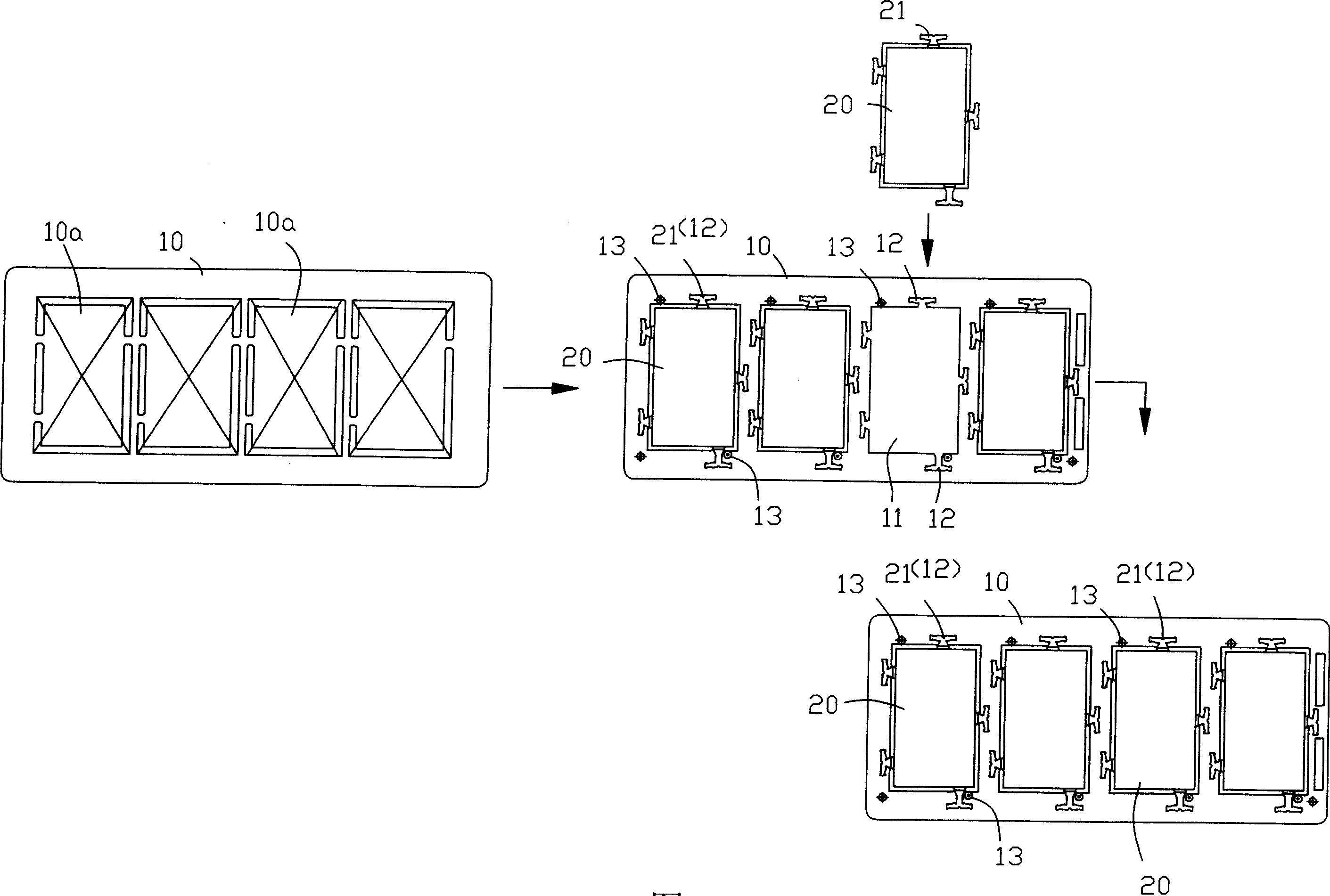

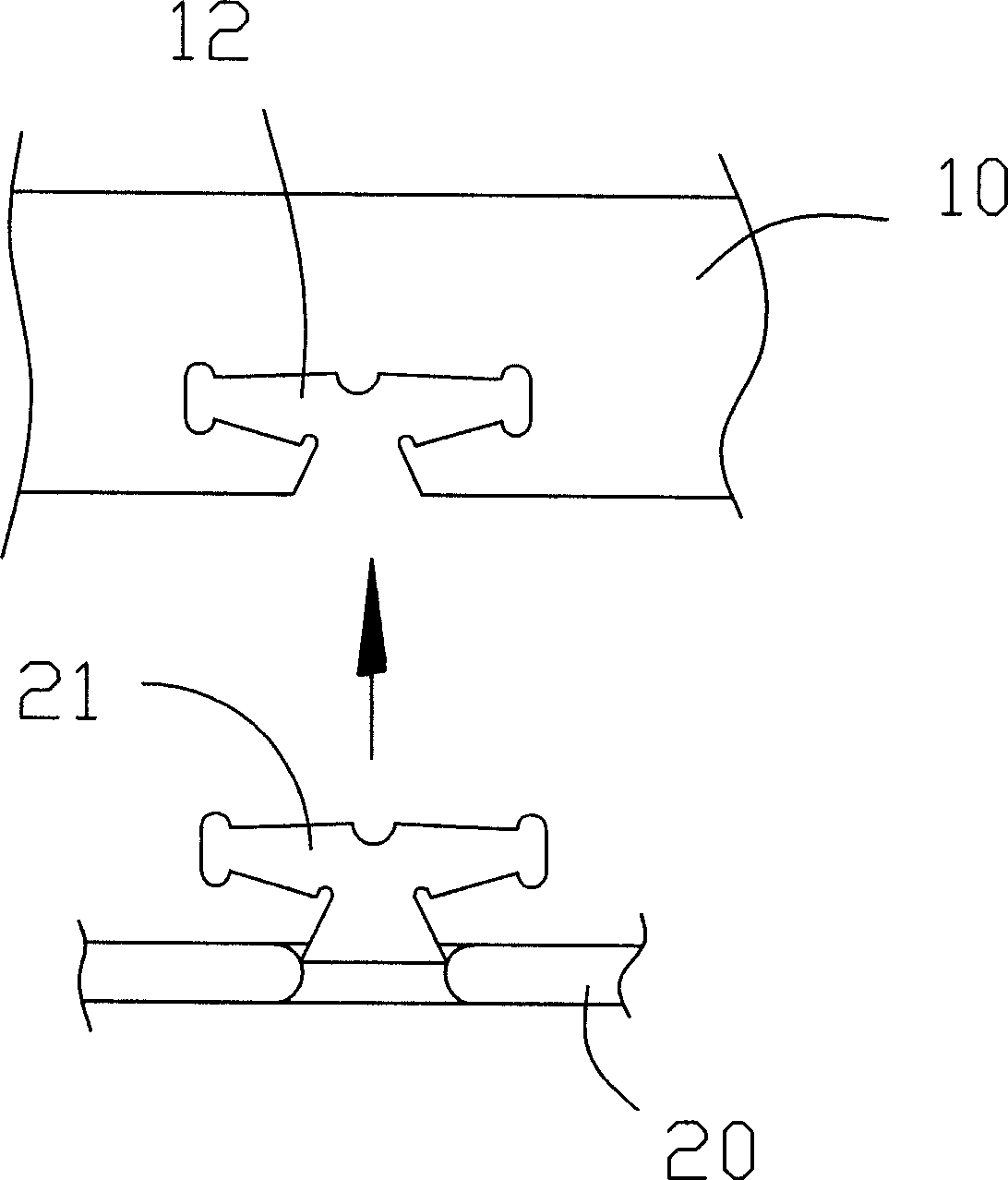

[0024] The present invention mainly includes the following steps: removing the defective printed circuit module in the first substrate 10; selecting the second substrate 20 with a good printed circuit module; embedding the second substrate 20 in the defective printed circuit module in the first substrate 10 The position of 10a realizes replacement. When removing the bad printed circuit module 10a of the first substrate 10, process this part into a corresponding shape and size of accommodating groove 11, and extend one or more than two embedding ports 12 on the edge of the accommodating groove 11; The base plate 20 is made as a plate body matching the shape and size of the above-mentioned receiving groove 11 , and the second base plate 20 is provided with an ear buckle 21 which is inlaid and connected with the embedding interface 12 . The ear buckle 21 and the embedded inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com