Vortex compressor

A technology of scroll compressors and moving scrolls, applied in the field of scroll compressors, can solve the problems of unstable working conditions, limited use occasions, and shortened service life of compressors, and achieve compact structure, increased stability, and reduced power consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

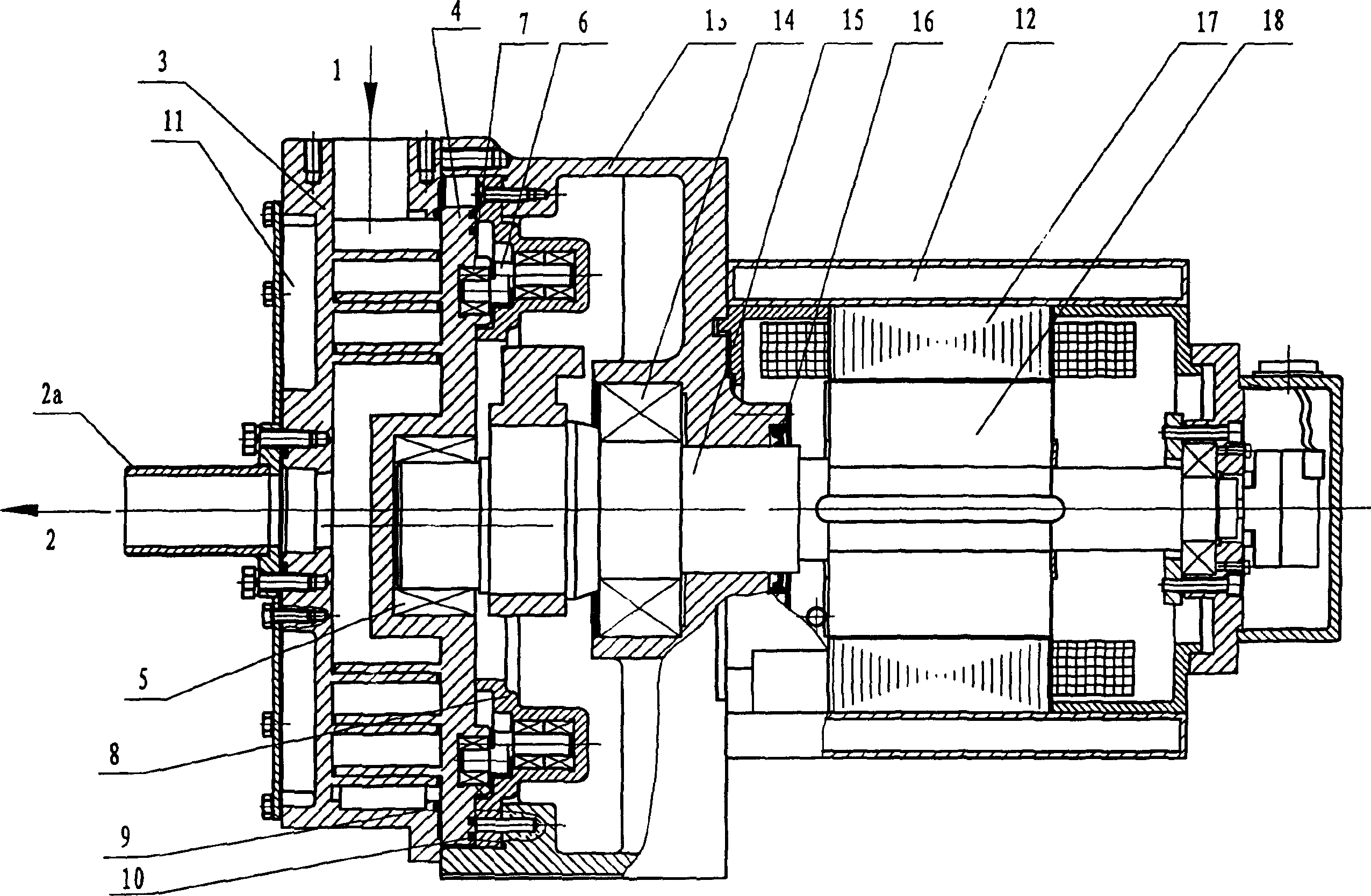

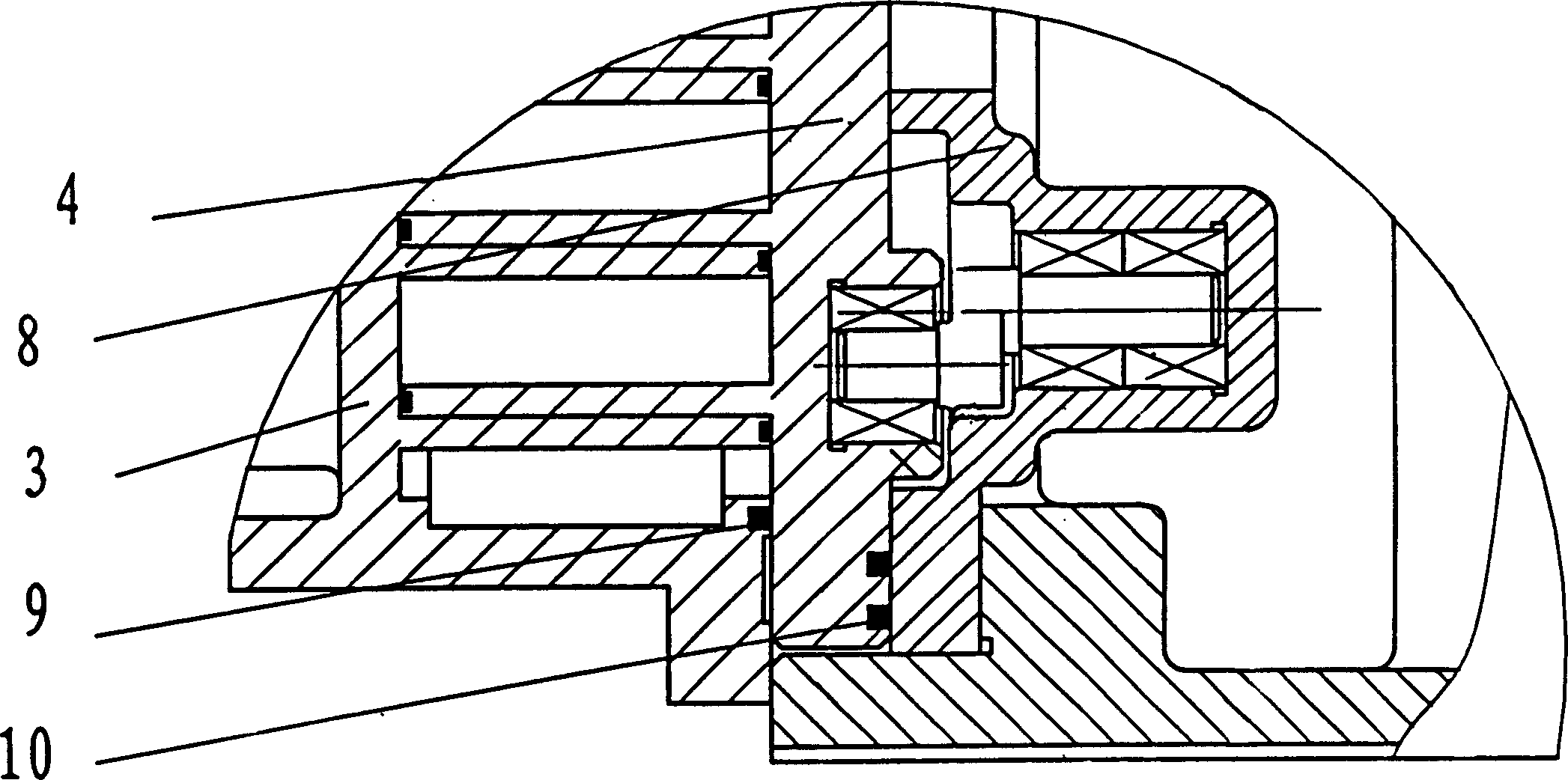

[0008] Such as figure 1 , figure 2 As shown, the compressed medium is inhaled through the suction port (1), and discharged through the exhaust port (2) after being compressed. The crankshaft (15) is installed on the support body (13) through the bearing (14), and the motor stator (17) Connected with the support body (13), the motor rotor (18) is directly installed on the crankshaft (15), driving the movable scroll (4) to perform rotary and translational motions, and the scroll teeth on the movable scroll (4) are in contact with the static The scroll teeth on the scroll (3) are staggered and meshed to form a closed compression chamber, which is composed of an orbiting scroll (4), a small bell crank (6), a bearing (7) and a support insert (8) to prevent rotation Mechanism, the upper end of the small crank throw (6) is embedded in the end plate of the movable scroll (4) through the bearing (7), the lower end is installed in the supporting embedded iron (8), and the supporting e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com