Light guide plate with analogous triangular prism structure

A triangular prism and light guide plate technology, applied in prism, optics, nonlinear optics, etc., can solve the problems of panel waste, cost reduction, light energy loss, etc. of liquid crystal displays, and achieve brightness improvement, manufacturing cost reduction, cost control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

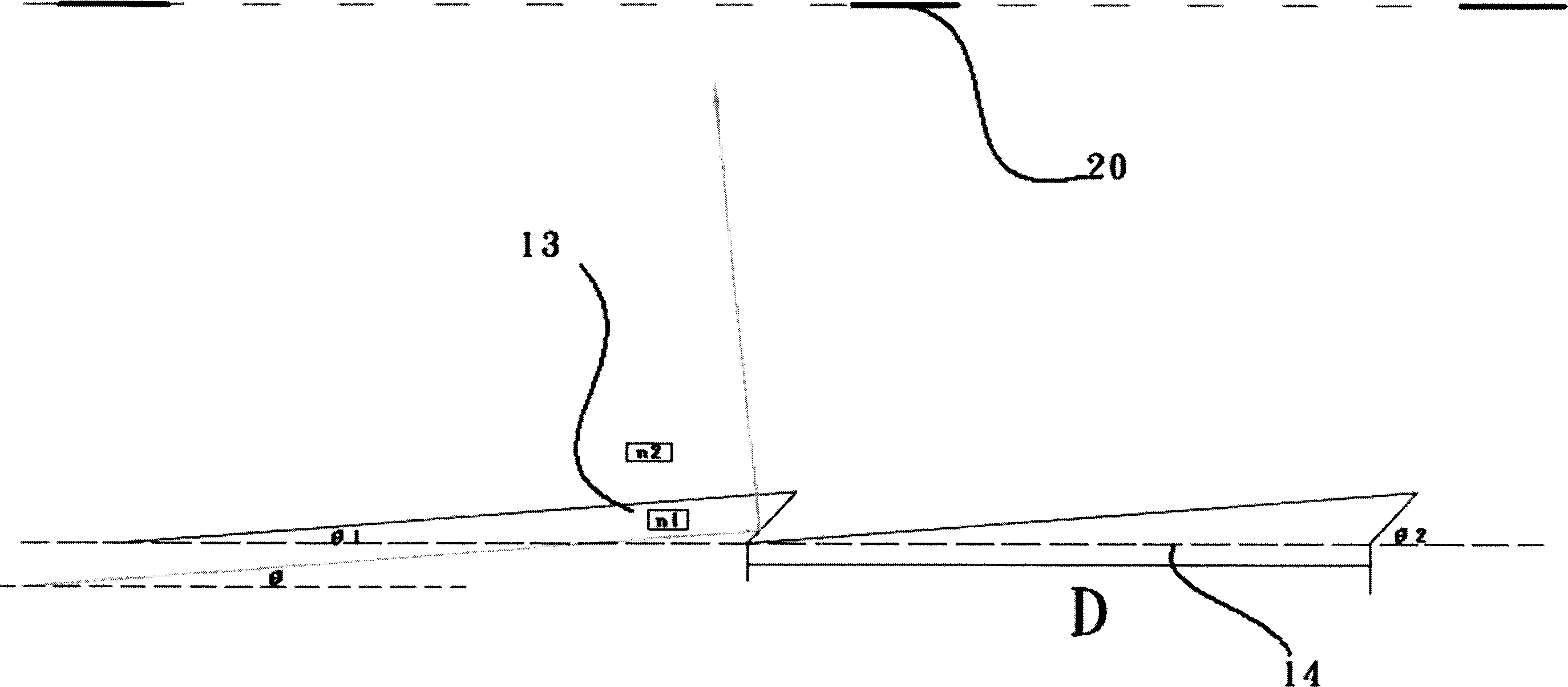

[0055] The present invention is a light guide plate with triangular prism structure, such as figure 1 As shown, the arrangement of the quasi-triangular prisms 13 is a neatly arranged obtuse triangle, wherein D is the width of the bottom surface 14 of the quasi-triangular prism, and the width of the quasi-triangular prism bottom just corresponds to the distance from the opening 20 of the panel of the liquid crystal display, so that the light passes through The light emitted by the total reflection inside the quasi-triangular prism 13 just corresponds to the opening 20 of the panel of the liquid crystal display, so that the light energy is effectively used, the brightness can be improved, and the picture quality of the liquid crystal display can be improved.

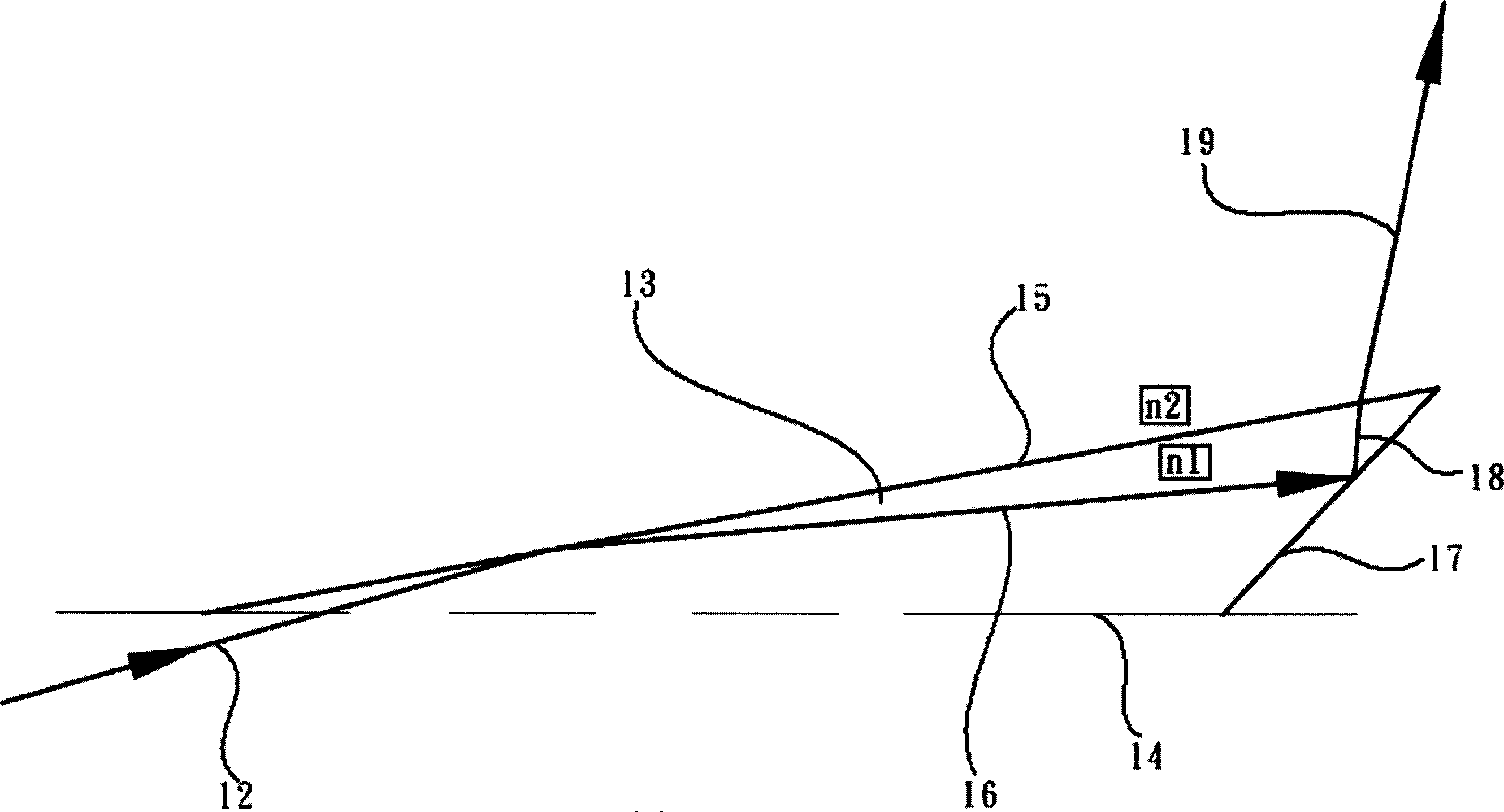

[0056] cooperate again figure 2 and Figure 6-1 As shown, it is one of various light angles entering it, wherein the light is injected into the light guide plate 11 by the light source 10, and then the incident light 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com