Superposition gear wheel with wide tooth form

A tooth profile and gear technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem of precise design of tooth profile and complex manufacturing process, and difficulty in multiplying the torque strength of gears , No major breakthroughs and other issues have been achieved, and the production cost is low, which is conducive to thinning and miniaturization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

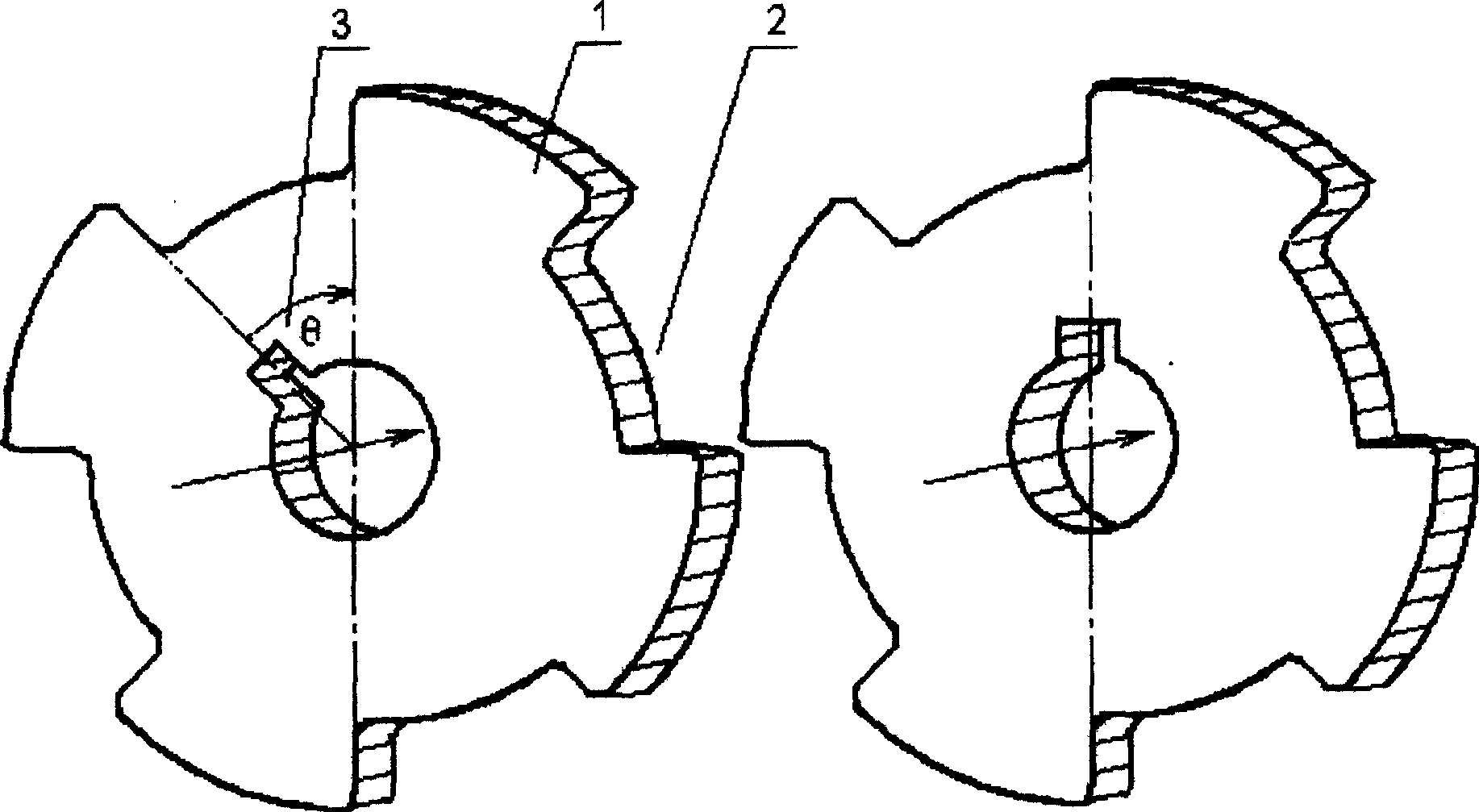

[0038] The gears can be stacked coaxially in series, with or without intervals in the middle, and can also be fixed together with connectors. The gears of this superposition mode are easy to forge processing and tooth profile repair, but the strength is not ideal enough. The other is the combined forging of two gears, the top of the tooth end and the corner point are trimmed for cutting, and the other parts can be considered for abrasive jet polishing. Regardless of whether it is an ordinary gear or a bevel gear with different radii, as long as the forging accuracy can meet the requirements, the latter should be preferred, which can further improve the strength.

Embodiment 2

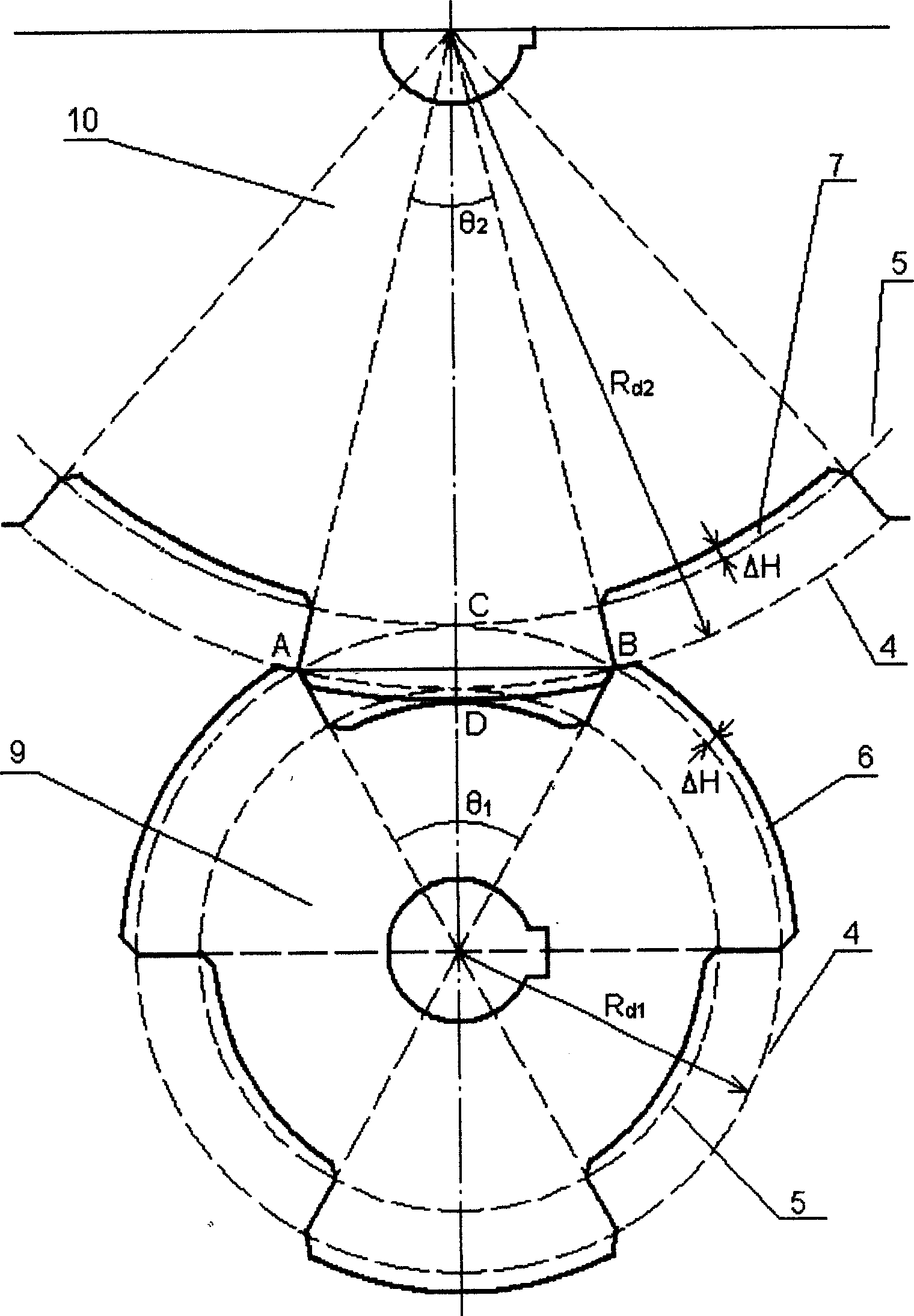

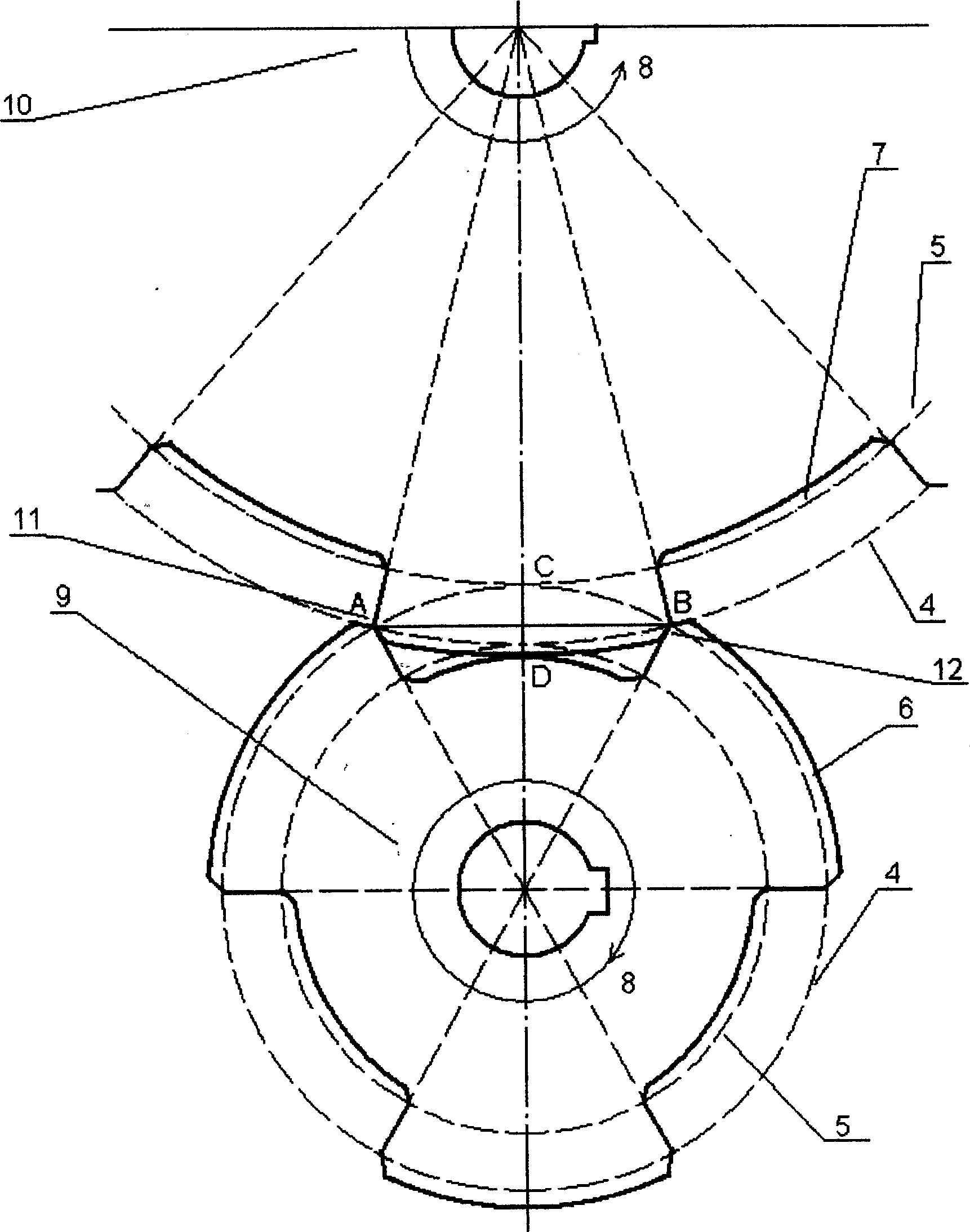

[0040] For planetary gears, the node distance CD in formula (1.3), see Figure 6, should be changed to:

[0041]

[0042] It will result in less sliding distance and wear on the tooth flanks on the nodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com