Engine transmission method for forklift

A technology of engines and forklifts, which is applied in the direction of machines/engines, transmissions, mechanical equipment, etc., and can solve problems such as complex structures, difficult spatial arrangements, and poor lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

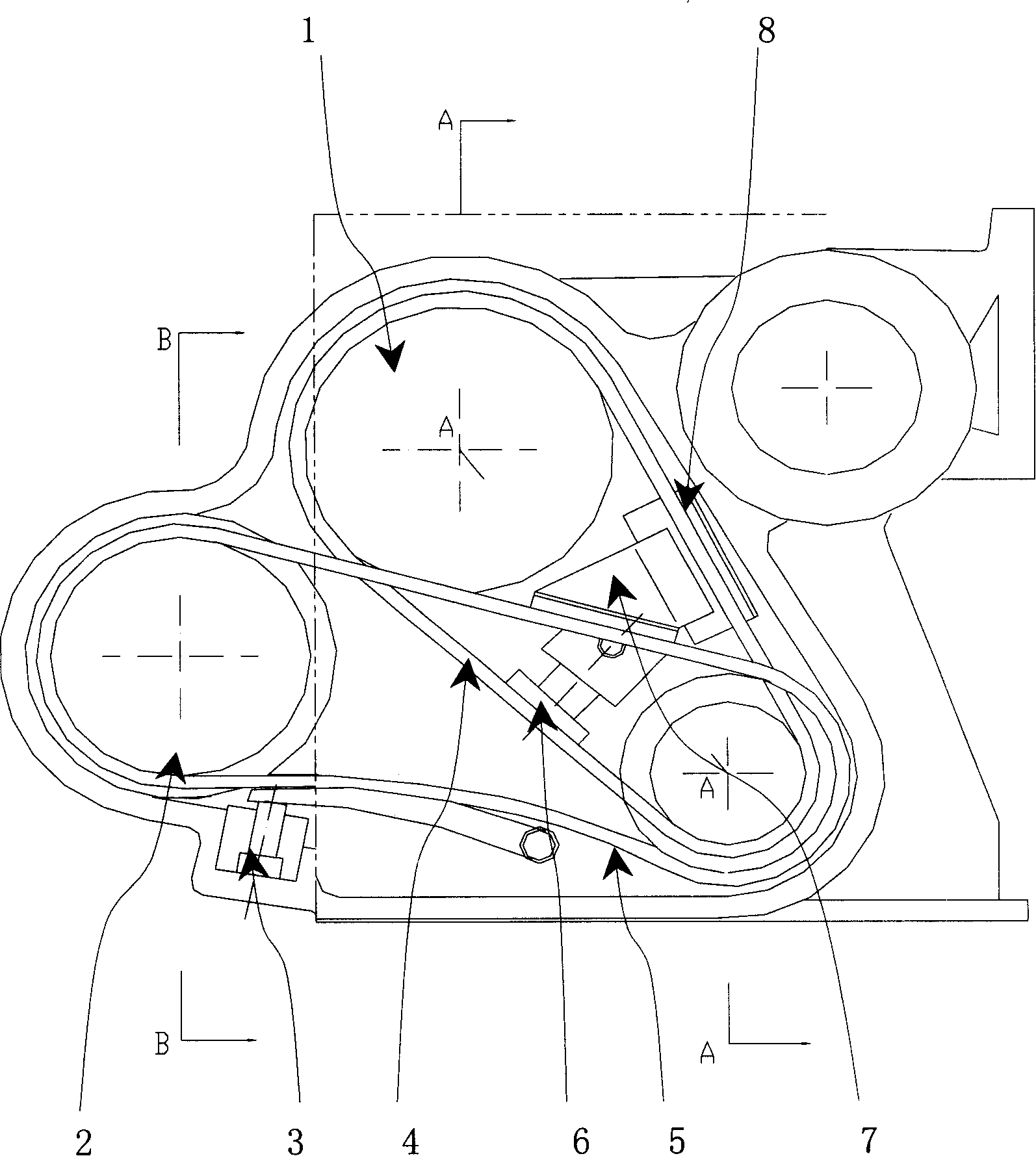

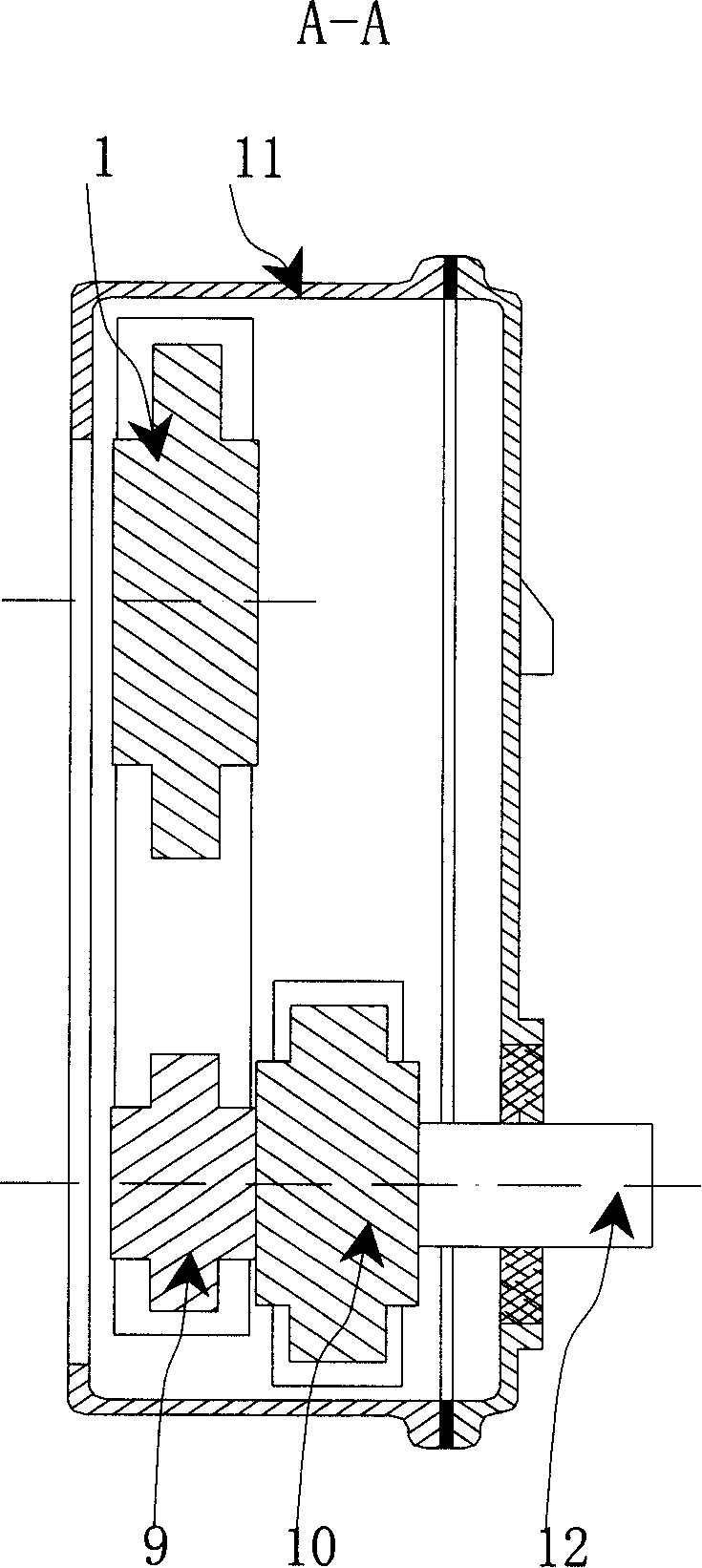

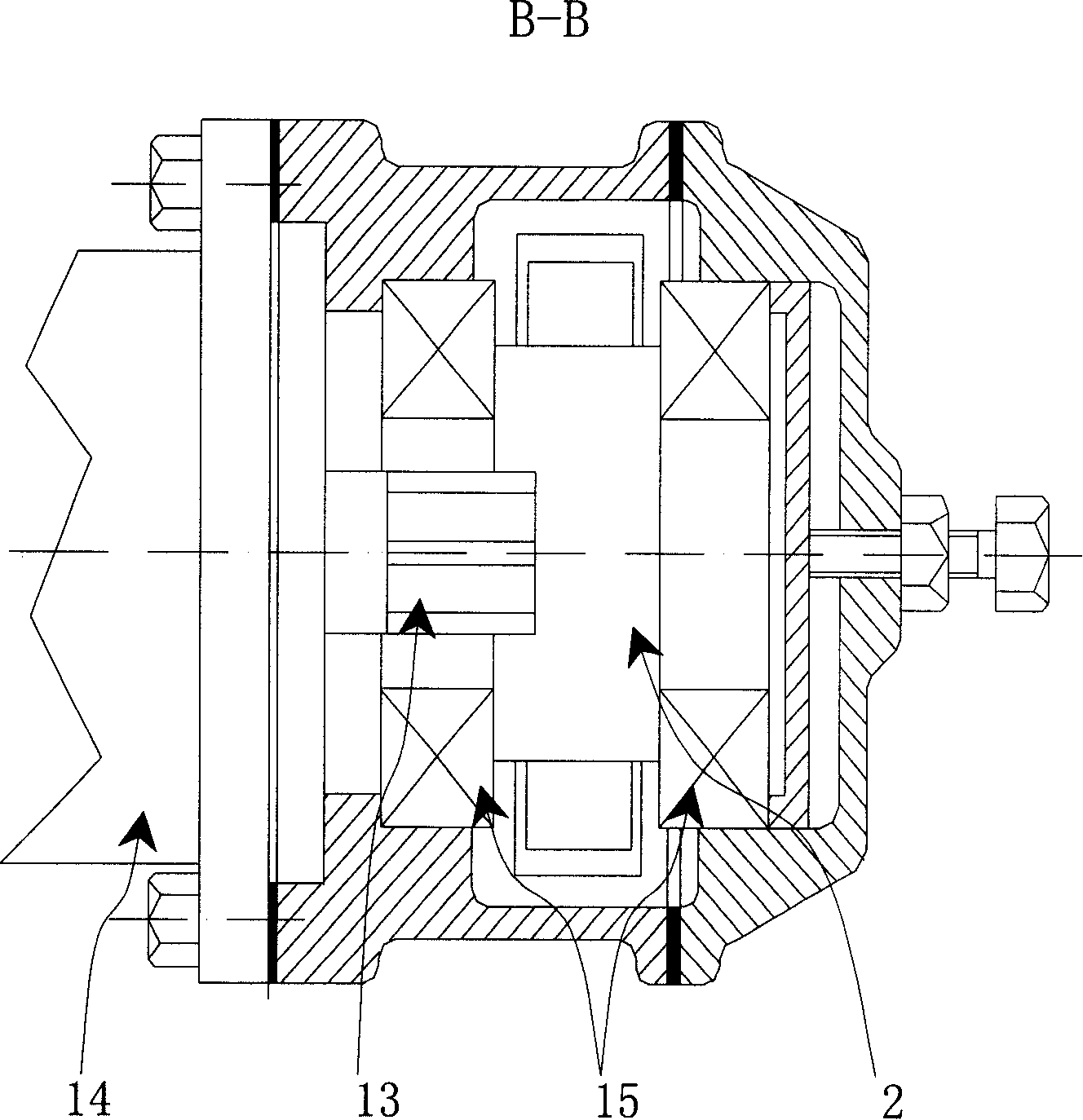

[0011] As shown in the figure, in the transmission method of an engine with a hydraulic pump for a forklift, in the sprocket chamber 11 of the engine with a hydraulic pump for a forklift, in order to keep the timing transmission ratio unchanged, the original timing roller chain 4 and the camshaft timing chain are used. Wheel 1, crankshaft timing sprocket 9, timing chain damper 8 and timing chain tensioner 6. The power transmission of the toothed chain is realized in this way: when the engine outputs power, the toothed power drive sprocket 10 installed on the crankshaft 12 is transmitted to the toothed power output sprocket 2 through the toothed chain 5, and the toothed power output The two ends of the sprocket are positioned with two bearings 15; because the spline shaft 13 of the hydraulic pump 14 has been inserted into the spline groove of the toothed power output sprocket, the hydraulic pump is driven when the toothed power output sprocket 2 rotates. 14 rotate synchronously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com