Pipe connecting structure

A technology for connecting structures and pipelines, applied in the direction of pipeline layout, etc., can solve the problems of poor connection, damaged sealing ring, unreliable construction of missed inspection, etc., and achieve the effect of good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

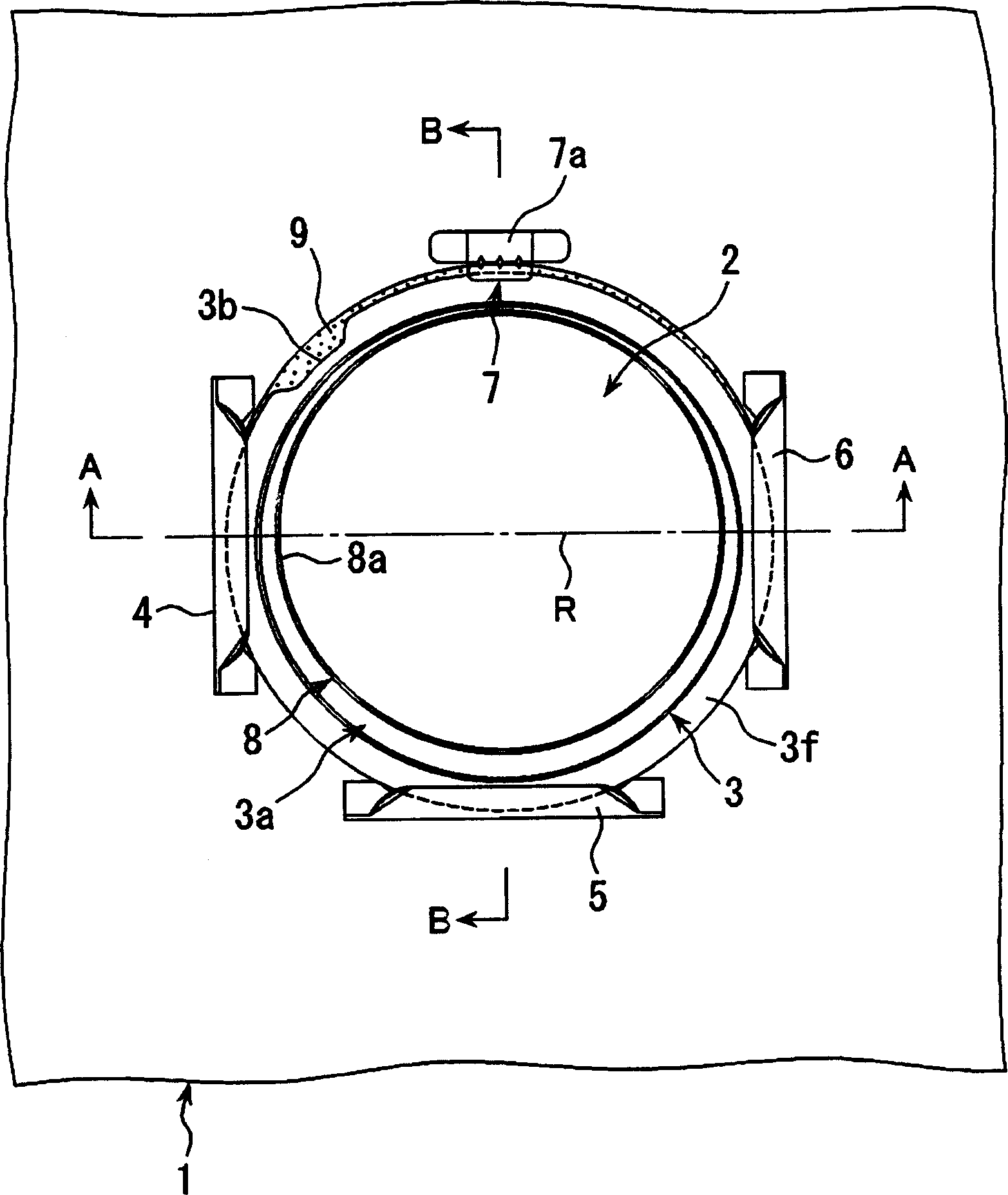

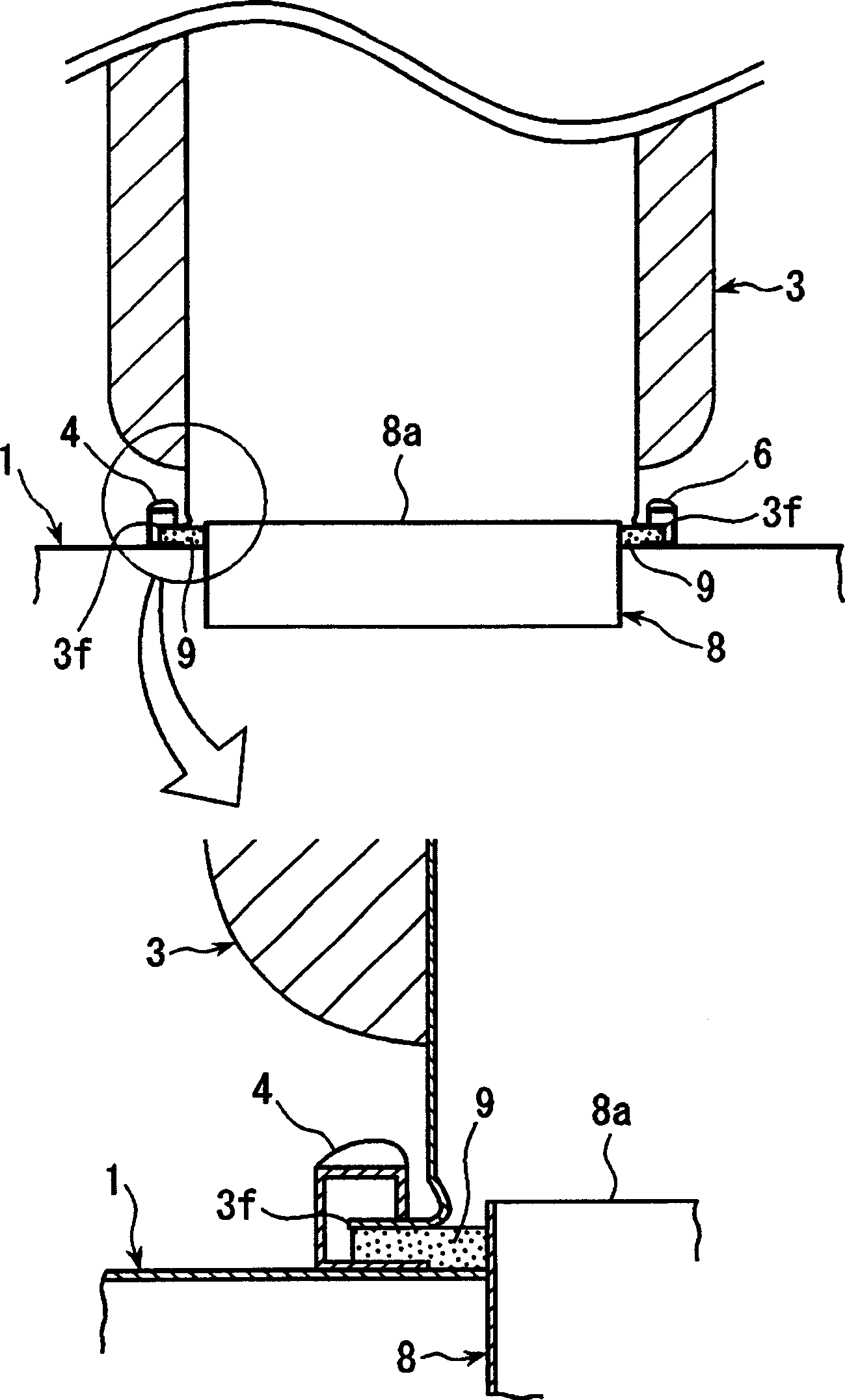

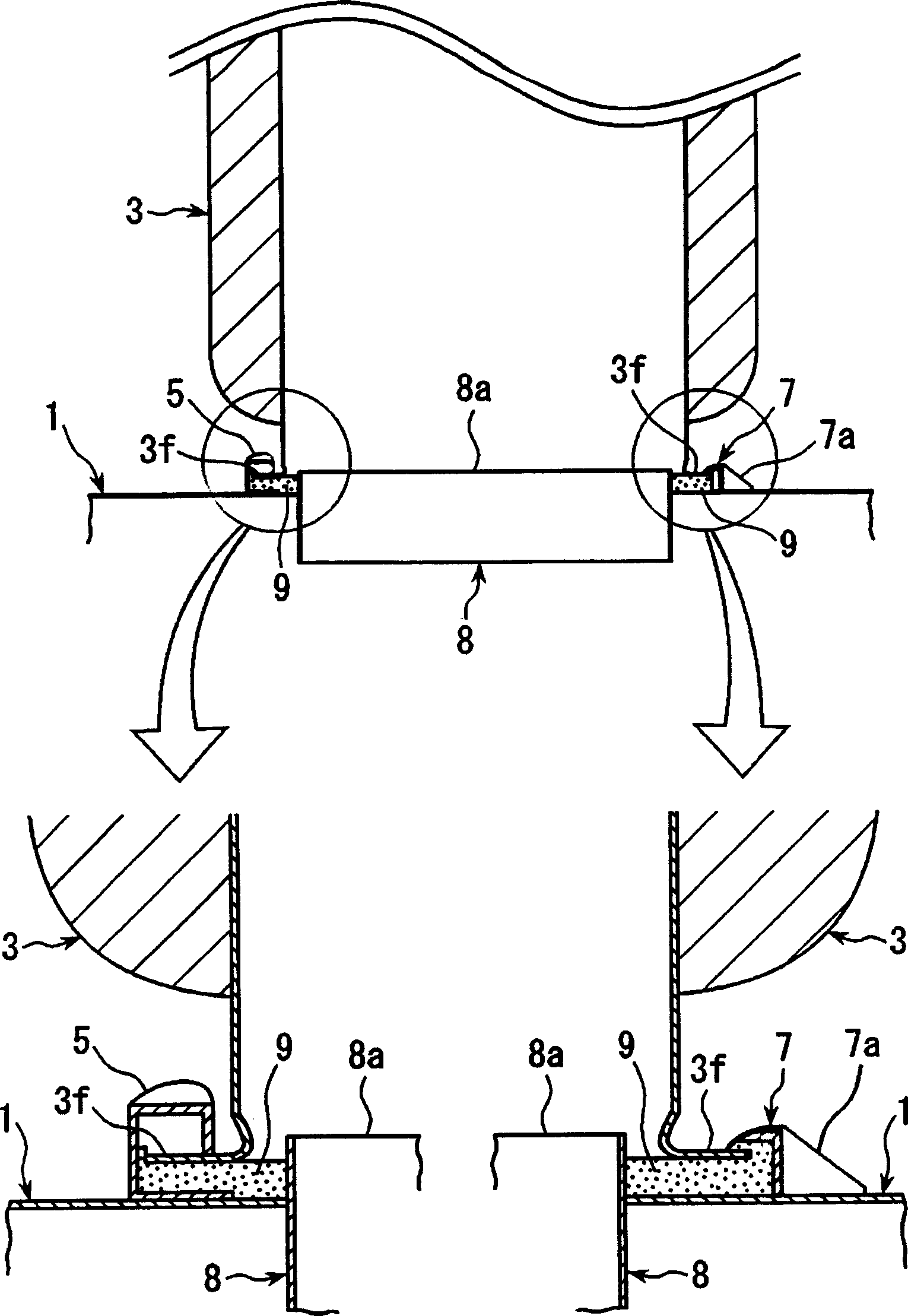

[0047] figure 1 It is a partially omitted front view showing a pipe connection structure according to an embodiment of the present invention; figure 2 yes figure 1 A sectional view along line A-A of ; image 3 yes figure 1 The sectional view along the B-B line; Figure 4 is the composition figure 1 Partial cut-away side view of the pipe of the shown pipe connection structure; Figure 5 yes means Figure 4 a drawing of the opening of the duct shown; Figure 6 is the composition figure 1 The front view near the pipe connection port of the shown pipe connection structure; Figure 7 is along Figure 6 Sectional view of line C-C; Figure 8 is along Figure 6 Sectional view of line D-D.

[0048] Such as Figure 1 ~ Figure 3 As shown, the duct connection structure of this embodiment is a connection structure provided at the duct connection port 2 of the hollow box-shaped air conditioner 1 and the opening 3a of the cylindrical duct 3 . In this duct connection struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com