Semiconductor device having tin-based solder layer and method for manufacturing the same

A solder layer, semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

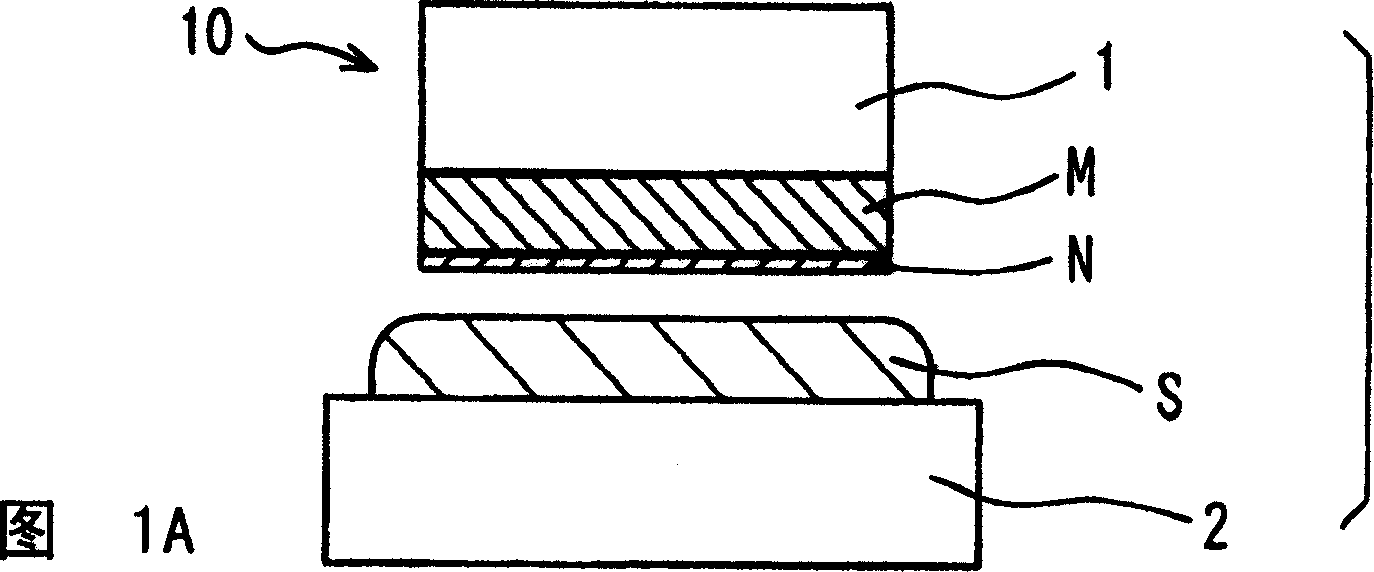

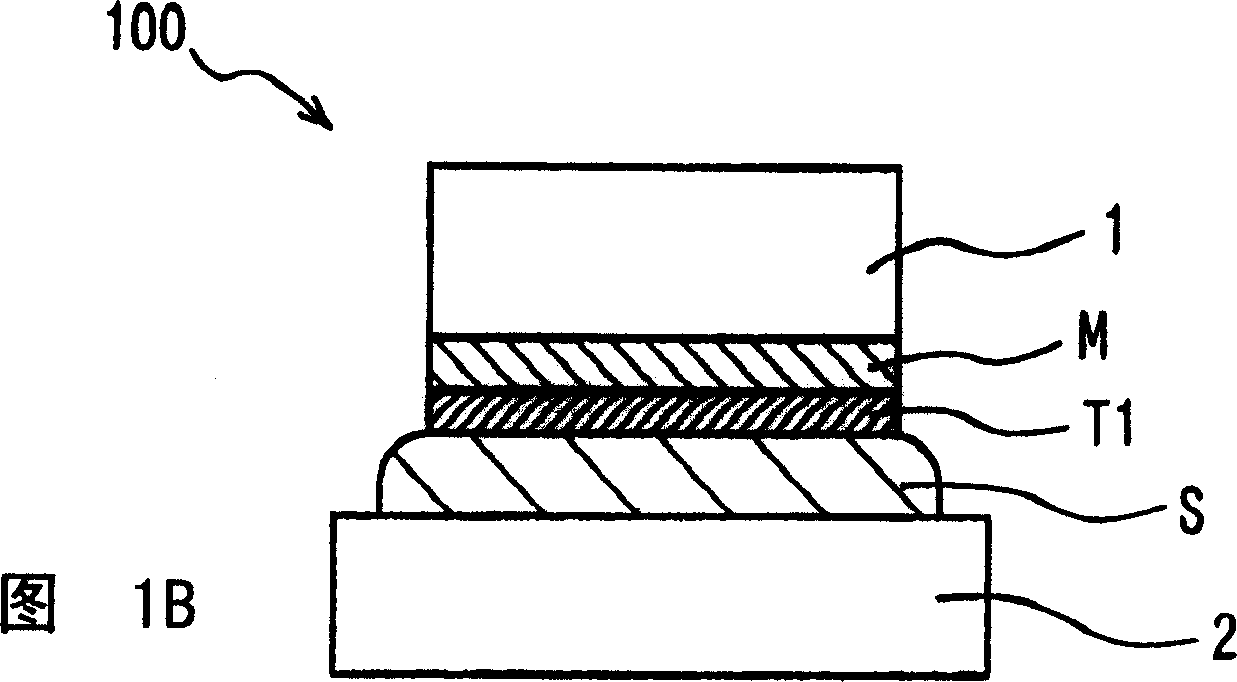

[0025] A semiconductor device 100 according to a first embodiment of the present invention is shown in 1A and 1B. FIG. 1A shows the device 100 before heat treatment, ie before soldering, and FIG. 1B shows the device 100 after heat treatment, ie after soldering.

[0026] The device 100 includes a semiconductor substrate 1 and a base member 2 . The substrate 1 has electronic components, such as power transistors, formed on the front side of the substrate 1 . The backside of the substrate 1 opposite the semiconductor component is bonded to the base component 2 with a layer S of tin-based solder. The base member 2 is, for example, a heat sink, a lead frame, or a circuit board. Device 100 was fabricated as follows.

[0027] First, electronic components are formed on the front side of the substrate 1 . A first metal layer M and a second metal layer N are sequentially formed on the backside of the substrate 1 . Thus, the semiconductor chip 10 is formed. Then, the chip 10 is mou...

no. 2 example

[0044] A semiconductor device 101 according to a second embodiment of the present invention is shown in Figure 6A to 6C. Figure 6A shows the chip 10 prior to the first heat treatment, Figure 6B The chip 10 after the first heat treatment and the base member 2 before soldering are shown. Figure 6C shows the device 101 after the second heat treatment, ie after soldering.

[0045] Device 101 was fabricated as follows. First, a first metal layer M and a second metal layer N are sequentially formed on the backside of the substrate 1 to prepare the semiconductor chip 10 . Chip 10 is first heated to form intermediate alloy layer O. The intermediate alloy layer O consists of a first metal and a second metal alloy. An intermediate alloy layer O is disposed between the first and second metal layers M, N. After this first heat treatment, the chip 10 is mounted on the base member 2 via the solder layer S. As shown in FIG. Then, the chip 10 and the base member 2 are heated a secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap