Material feeding pushing aid device for tube bending machine

A tube bending machine and boosting technology, which is applied to the feeding device, positioning device, storage device, etc., can solve the problems of low precision, bulging, and pipe slippage, and achieve high quality, high transmission precision, and simple mechanical structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

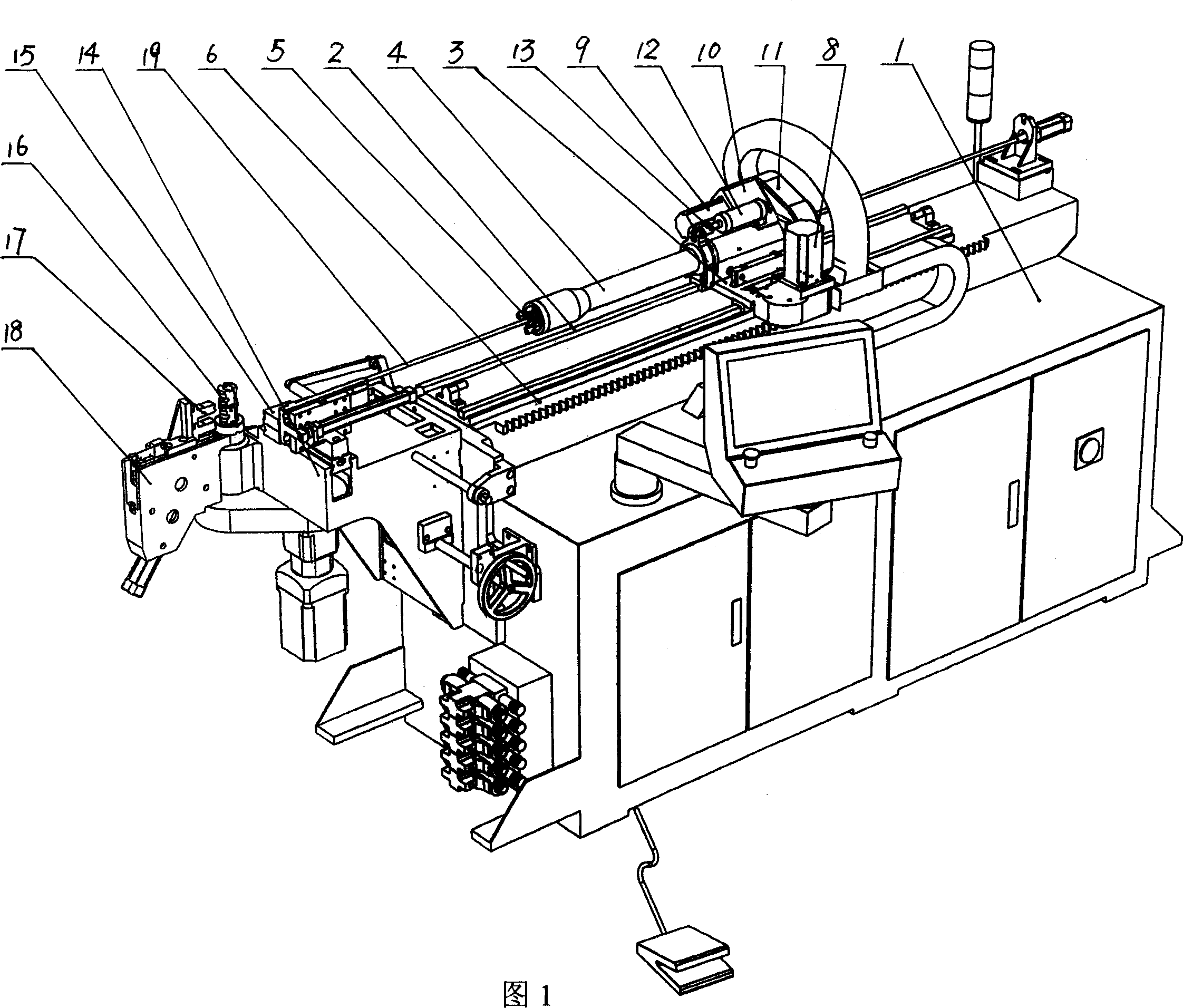

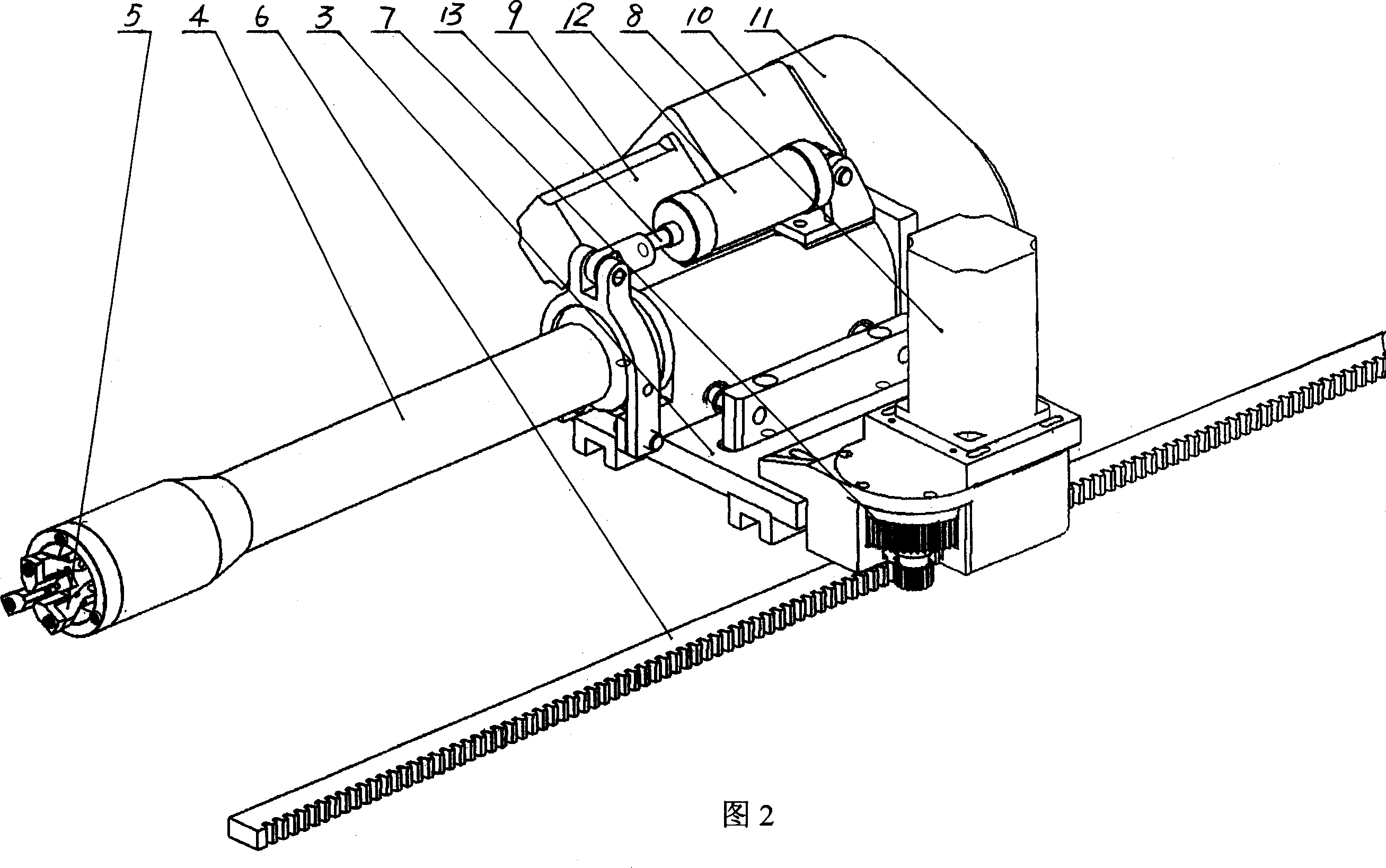

[0010] As shown in Figures 1 and 2, a feeding booster device for a pipe bender includes a feeding trolley 3 arranged on the guide rail 2 of the fuselage 1, a push-tight sleeve 4 and its transmission device arranged on the feeding trolley 3, and are arranged on the Push the clamp 5 at the end of the sleeve 4 and its driving device, a rack 6 is arranged on one side of the guide rail 2, and a gear 7 meshing with the rack 6 is arranged on the bottom side of the corresponding feeding trolley 3, and the gear 7 is driven by The device is connected with the servo motor 8, the servo motor 8 is connected with the computer automatic control device, and the computer automatic control device is not drawn in the figure; The rotary tube motor 9, the reduction gear 10 and the rotary tube gearbox 11 on the trolley 3 are composed, and the push-tight sleeve 4 is connected with the rotary tube gearbox 11; the driving device of the clamp 5 is also the prior art, which is usually a The clamping cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com