Film coating glass lens

A technology for coating glass and lenses, applied in instruments, coatings, optics, etc., can solve problems such as bending or deformation of glass substrates, affecting optical predetermined performance, affecting product quality, etc., to achieve the effect of increasing transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

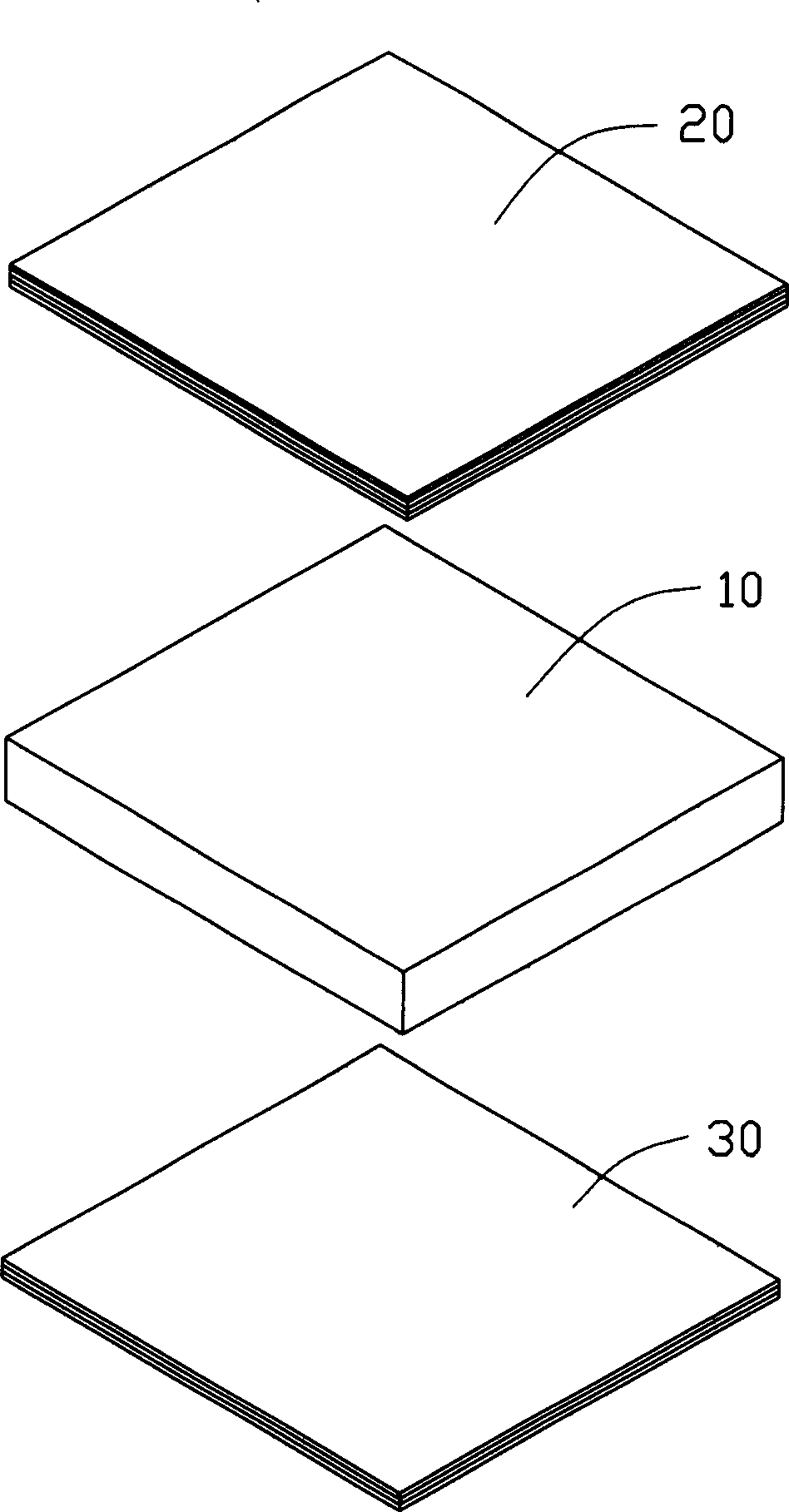

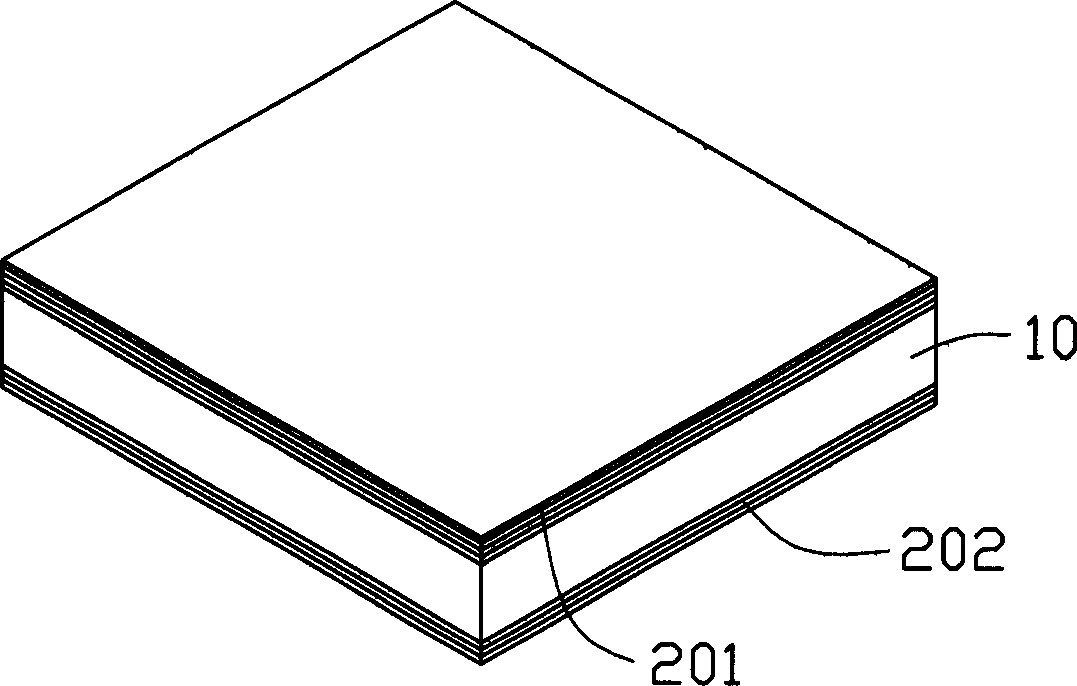

[0010] Please also see figure 1 and figure 2 The coated glass lens of the present invention comprises a glass substrate 10, a first film layer 20 and a second film layer 30, wherein the first film layer 20 is formed on the first surface of the glass substrate 10 by a multilayer optical film 201, The second film layer 30 is formed on the other surface of the glass substrate 10 corresponding to the first surface by a corresponding number of layers of anti-reflection coating (AR coating, Anti-Reflection coating) 301 .

[0011] The substrate 10 usually has a thickness of 0.175-0.3mm, or even thinner. The optical film 201 can be any one or a combination of filter films, spectroscopic reflective films, broadband multilayer films, and narrowband multilayer films. Infrared cut film (IR-CUT coating, Infra-Red coating) as an example, the multilayer optical film 201 is formed by stacking two kinds of high and low refractive index material films at intervals, wherein the high refractive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com