Batch production device, batch, and press form mounting method in batch production device

A technology of manufacturing device and extrusion die, applied in the field of badge manufacturing device, can solve the problems of moving drawing paper, unable to bend the surface plate, unable to manufacture uniformly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

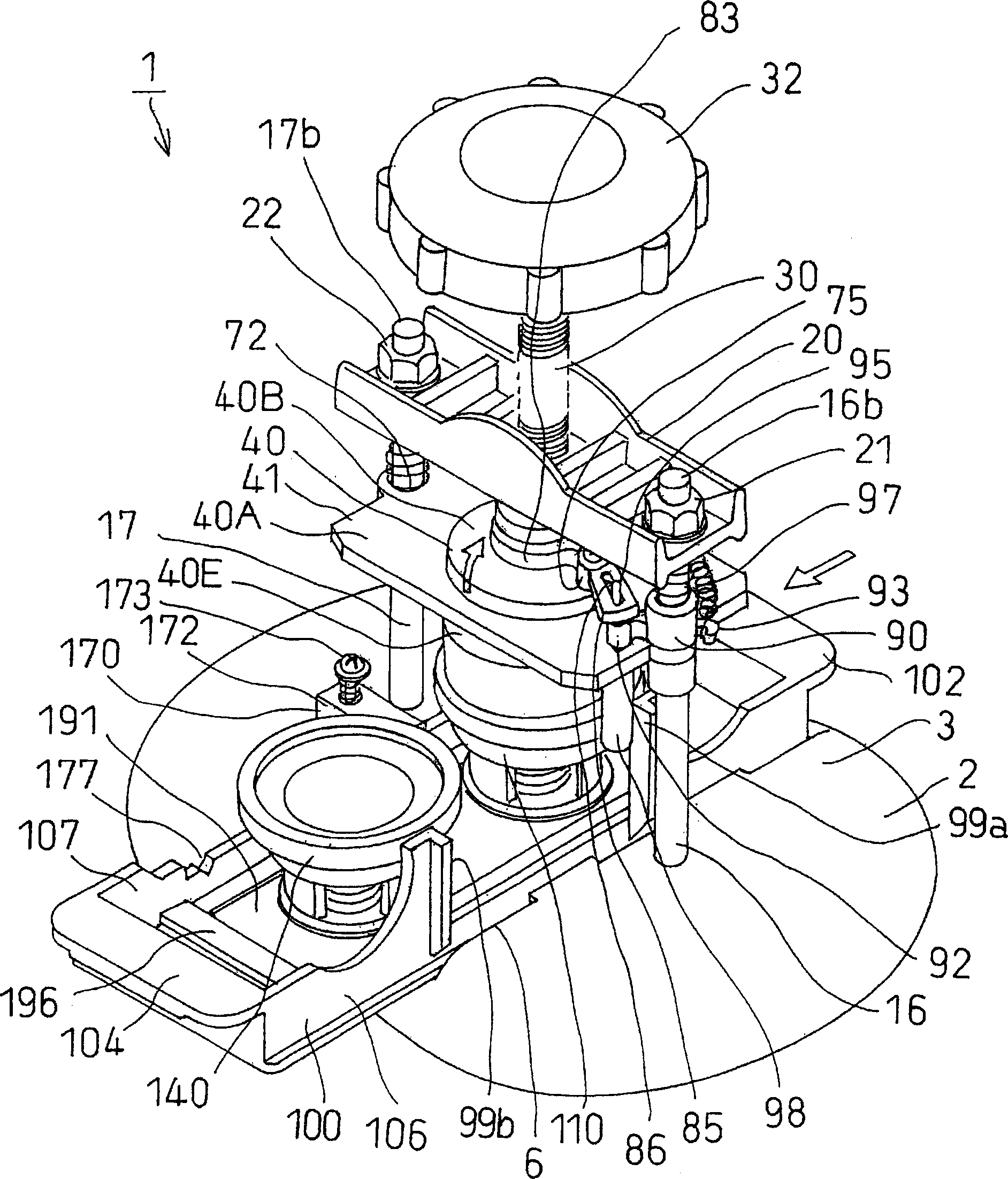

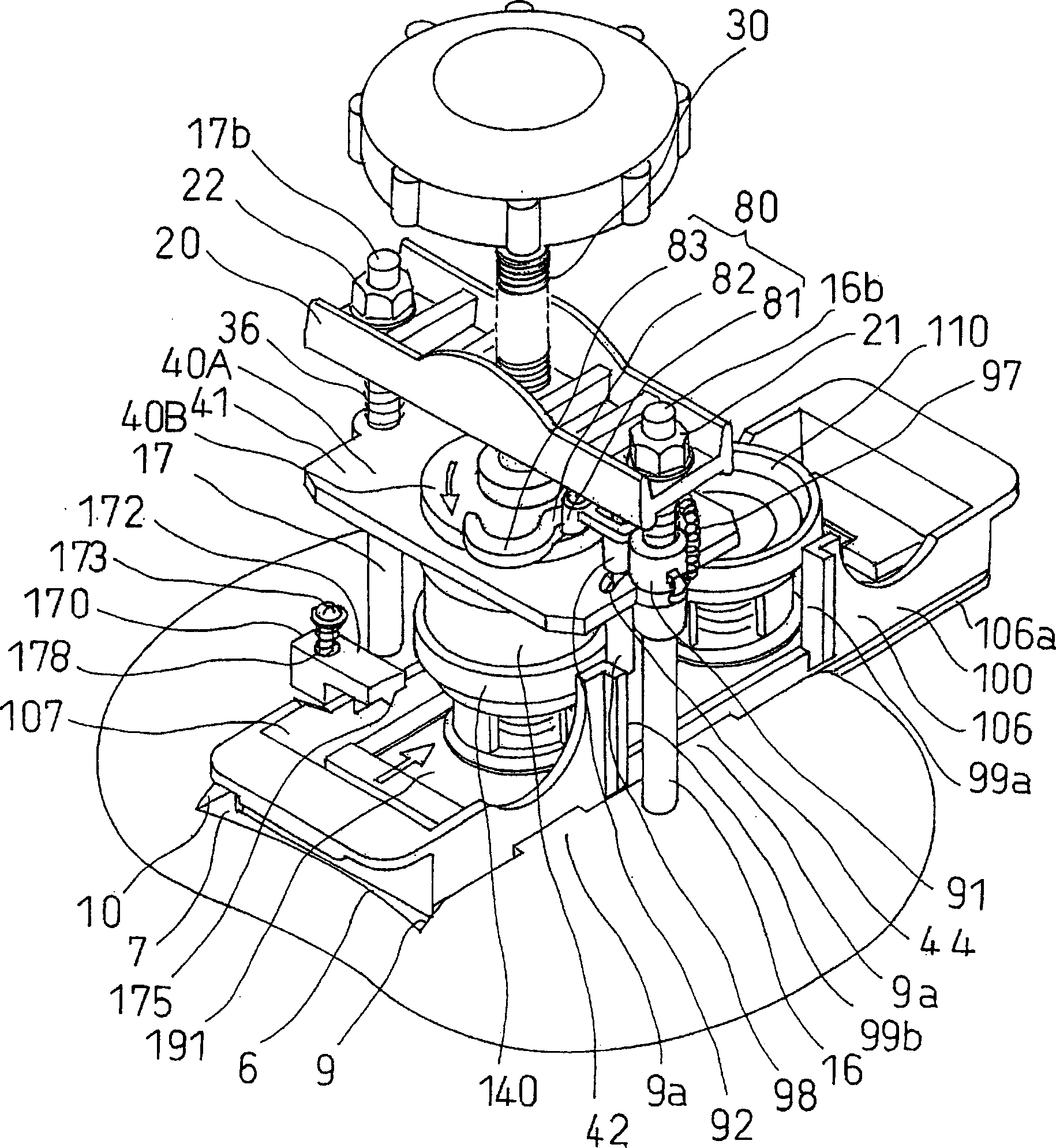

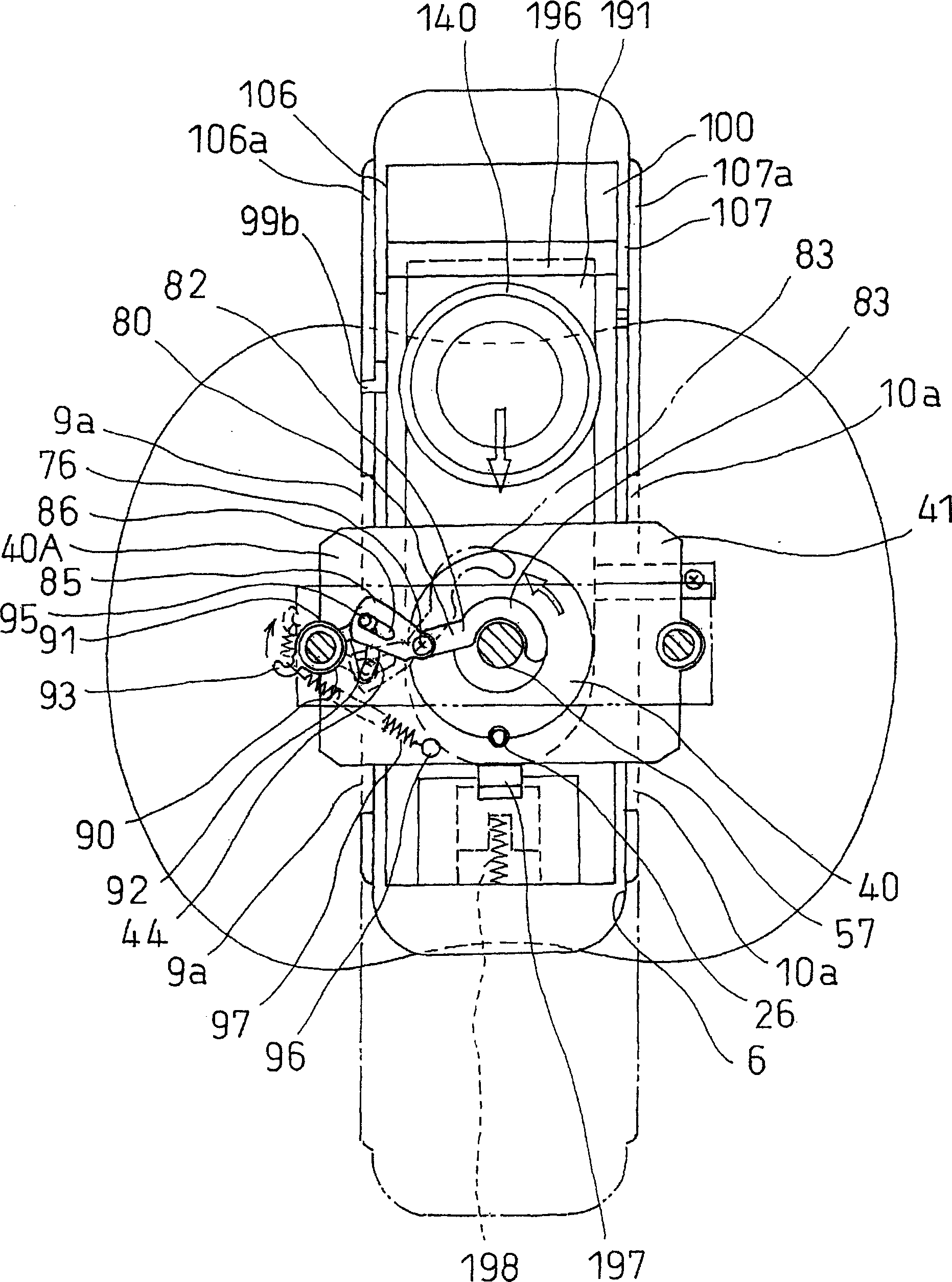

[0146] refer to Figure 1 to Figure 9 One embodiment of the emblem manufacturing apparatus according to the present invention will be described. figure 1 is an overall perspective view of the emblem manufacturing apparatus according to the present invention. figure 2 is description figure 1 Overall stereogram of the action. image 3 is description figure 1 An overall top view of the action. Figure 4 Yes figure 1 overall side sectional view. Figure 5 is an overall front sectional view showing the first die. Image 6 is description Figure 5 The overall front sectional view of the action. Figure 7 is an overall front sectional view showing the second die. Figure 8 is description Figure 7 The overall front sectional view of the action. Figure 9 It is a partially enlarged perspective view of the emblem manufacturing device.

[0147] The emblem manufacturing apparatus 1 is used to manufacture the following emblem, which includes: an outer cover 201 having a subst...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap