Winding device for removing cut binding material

The technology of a coiling device and a receiving part is applied in the field of a coiling device for taking away the cut binding material, which can solve problems such as hindering unbundling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

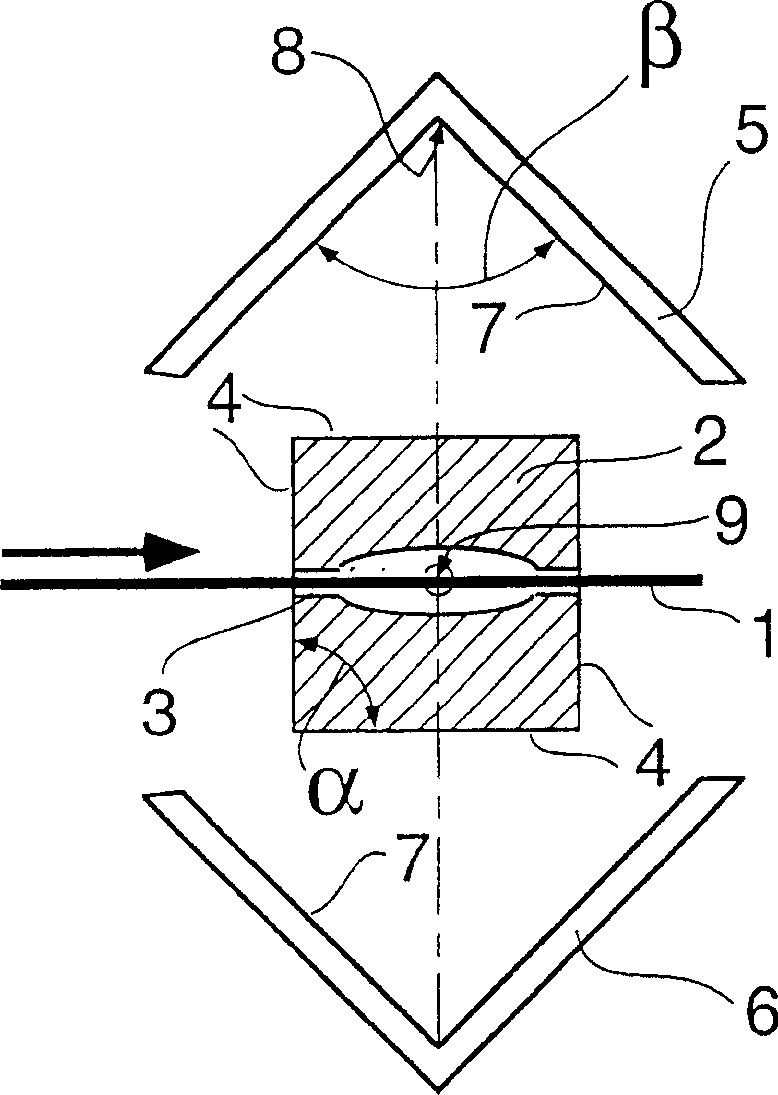

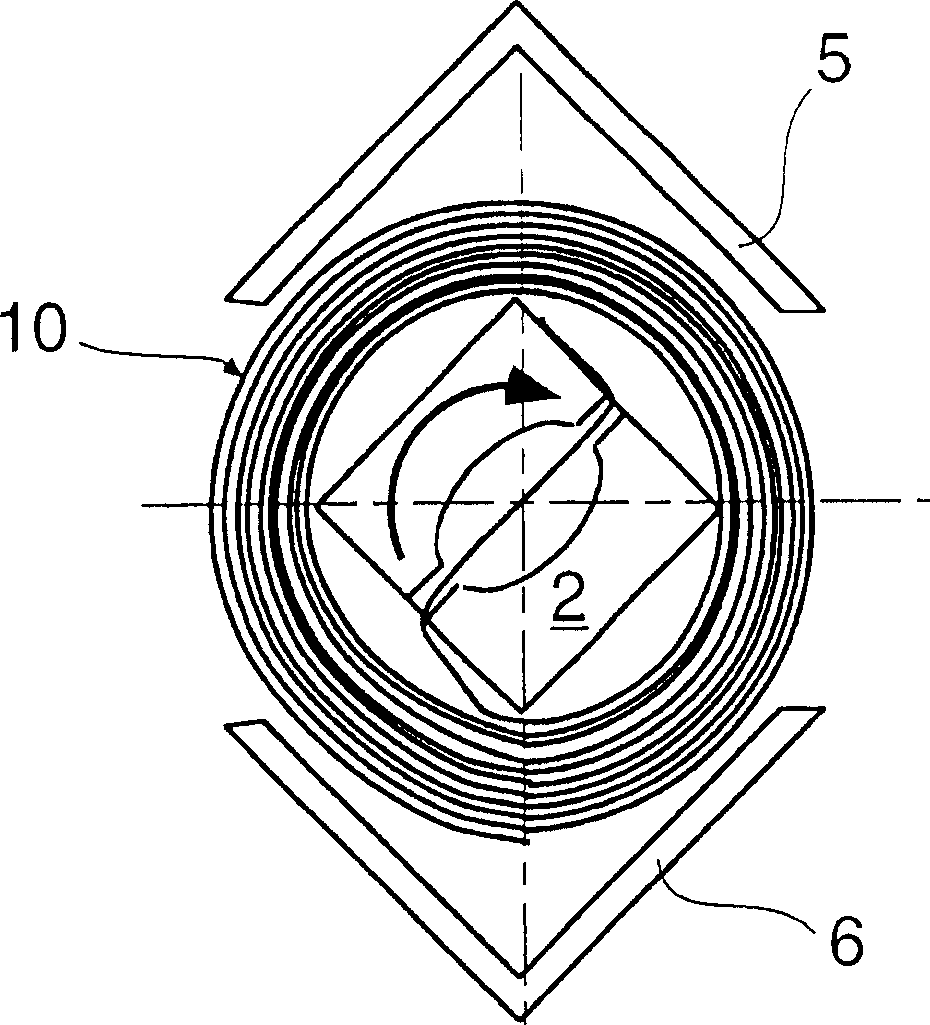

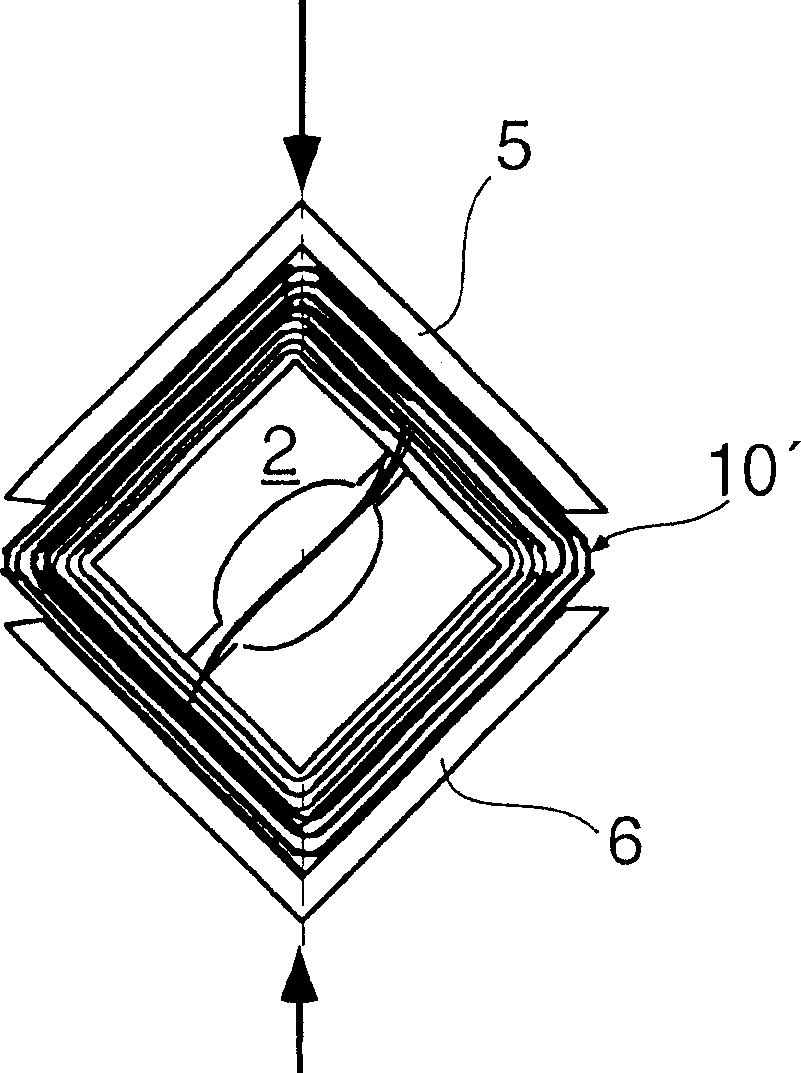

[0016] Figure 1a - 1d shows the components of the coiling device of the invention and the four main stages of its operation. The receptacle part 2 is placed with its winding surface 4 between the two extrusion parts 5 and 6 . Cutting off, loosening and slowly pulling out the binding material on the package is not shown in the figure. Next, the binding material is delivered to a suitable position facing the take-up device. exist Figure 1a In the state shown, the binding material 1 has been fed into the receiving groove 3 of the receiving element 2 . In this operating state, the two pressing parts 5 and 6 are at a greater distance from the receiving part 2, so that the binding material to be wound can assume the function of a guide. The inner surfaces of the pressing parts 5 and 6 respectively form a side wall opening toward the receiving part 2 at an included angle β=90°. The ridge line of the angle runs parallel to the axis of rotation 9 . Here, the cross section of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com