High-temp oxygen-enriched air fire lighting method for coal powder boiler and device thereof

An oxygen-enriched air, pulverized coal boiler technology, applied in the directions of combustion ignition, combustion method, incandescent ignition, etc., to maintain long-term stable operation, easy operation, and reasonable device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

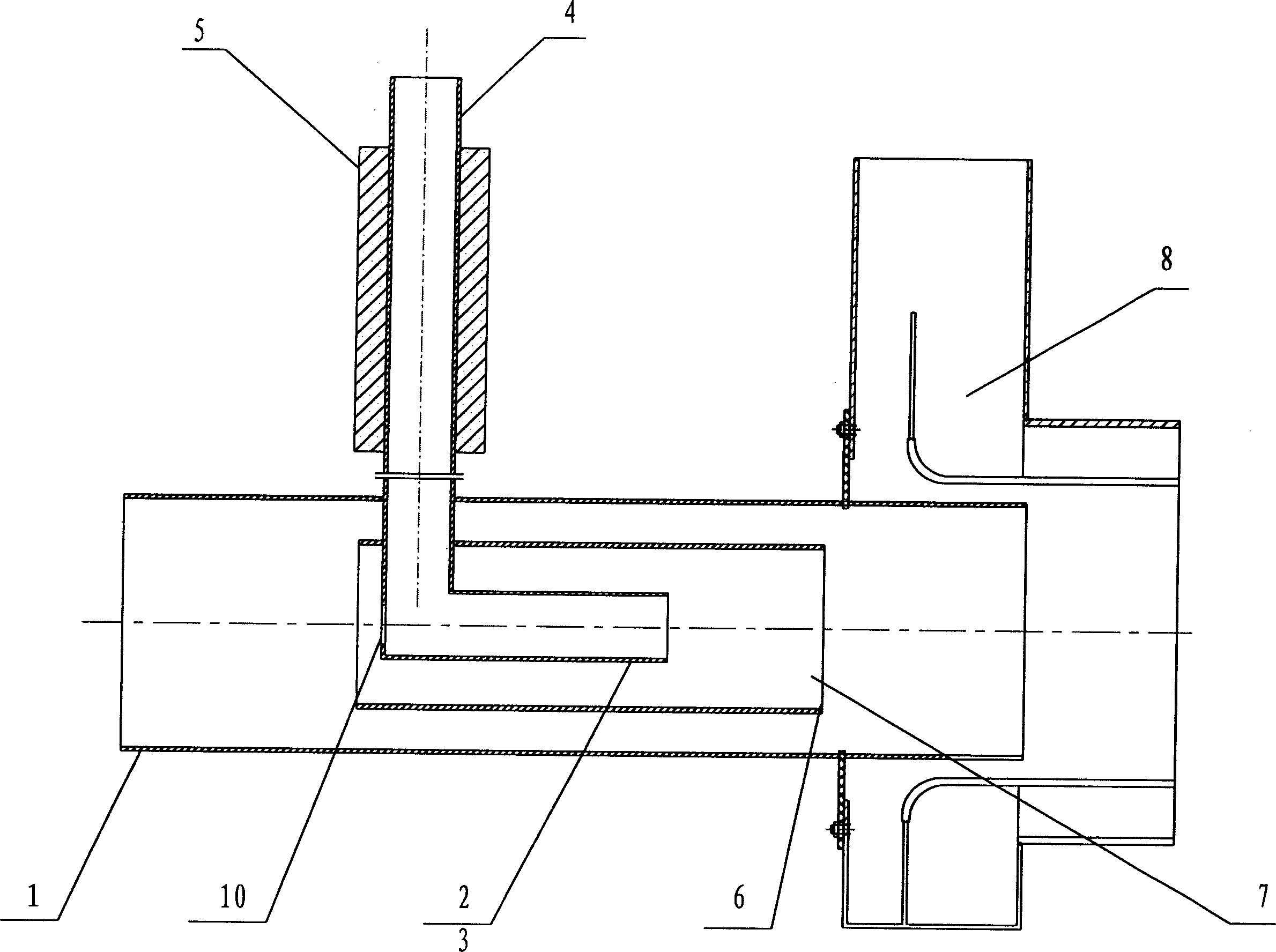

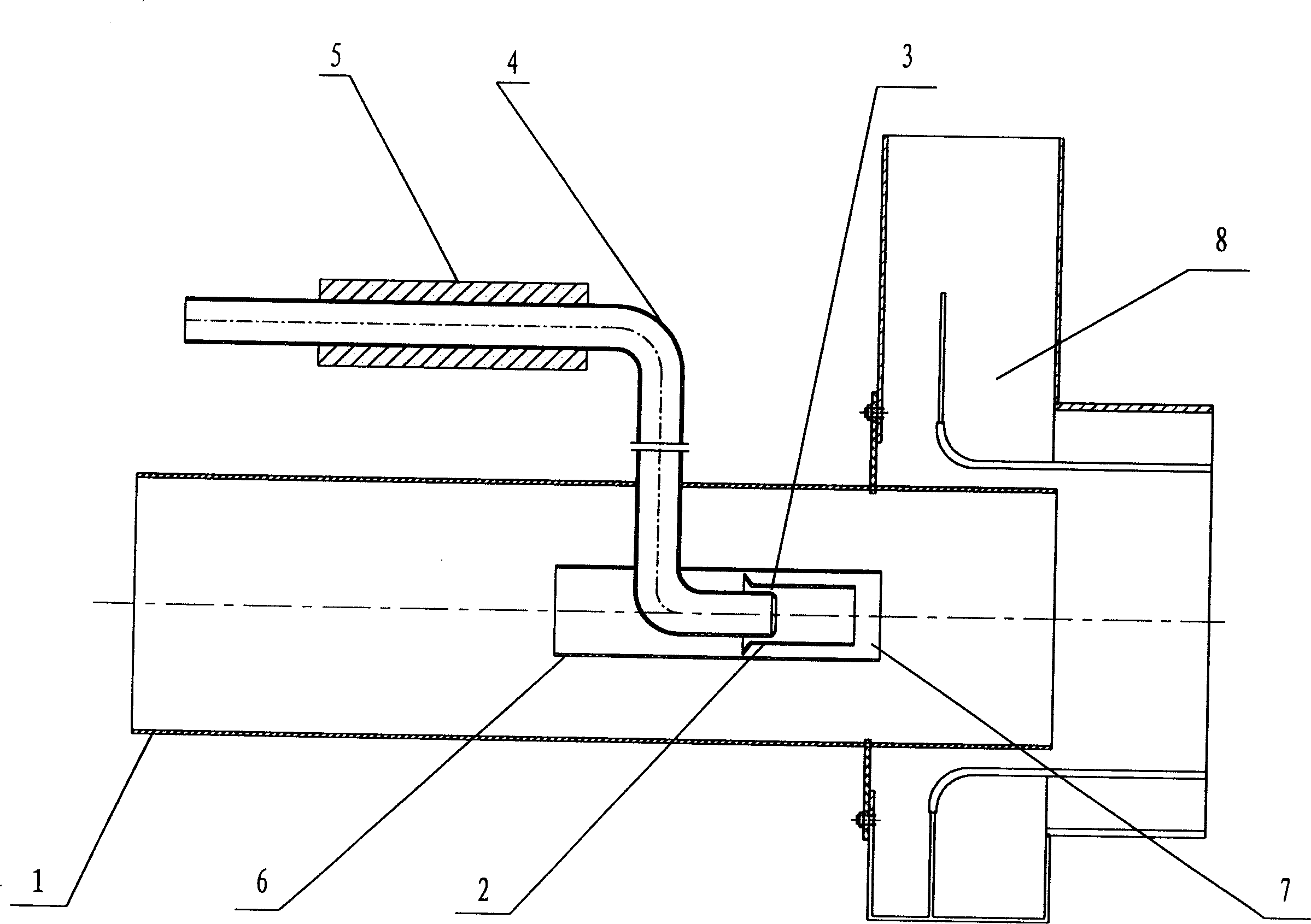

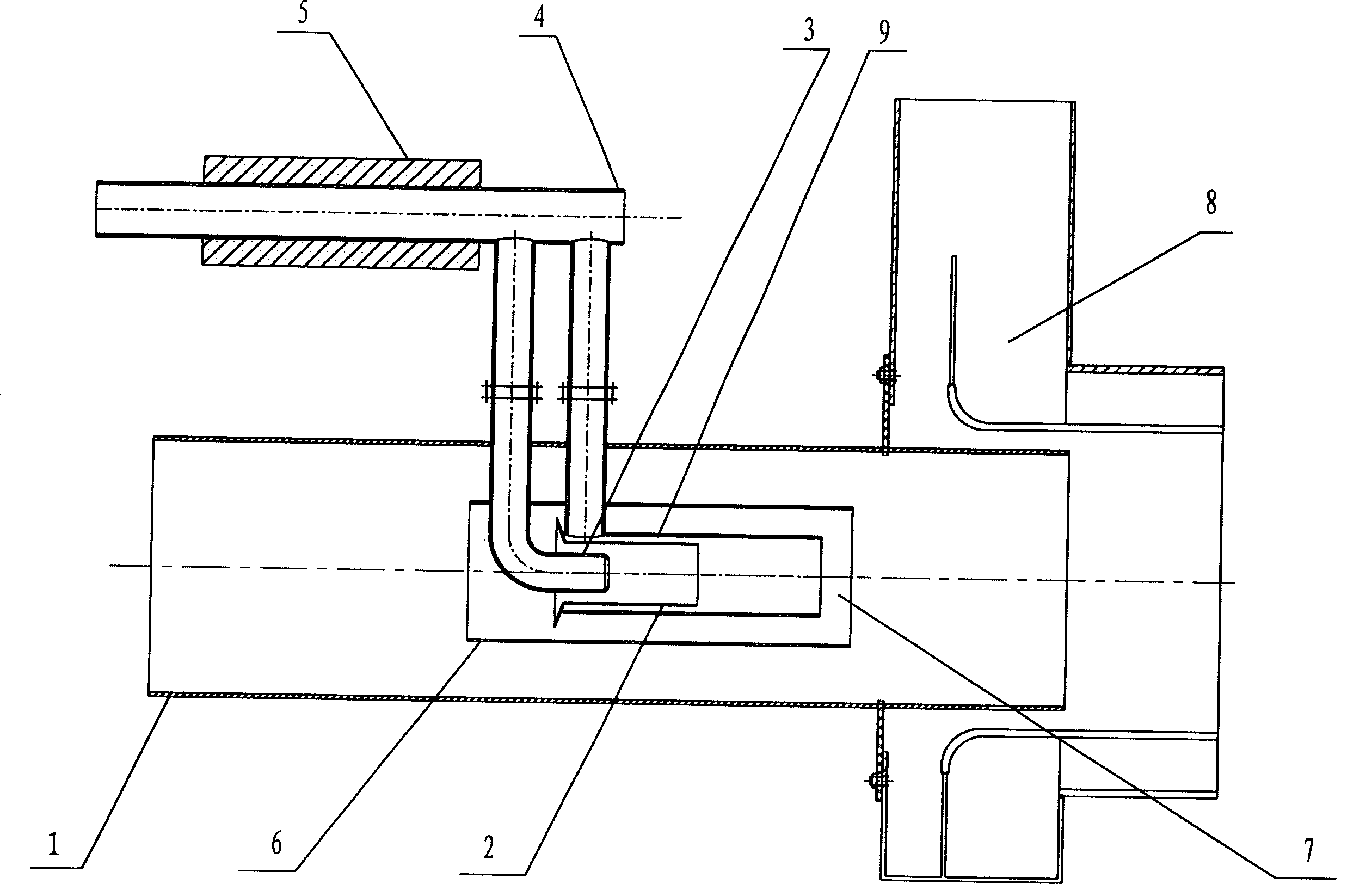

[0017] attached figure 1 It is the first implementation structure of the present invention. After the pulverized coal is carried into the pulverized coal pipe 1 by the primary air, it is divided into three parts: the small coal pulverized enters the ignition chamber 2 through the entrance 10 of the ignition chamber, that is, the high temperature oxygen-enriched chamber 3 and the The high-temperature oxygen-enriched air is mixed to form the first-level pulverized coal flow; another part of more pulverized coal enters the inner sleeve 6 of the pulverized coal pipe arranged outside the ignition chamber to form the second-level pulverized coal flow; most of the remaining pulverized coal is still in the pulverized coal The flow in the pipe forms a three-stage pulverized coal flow and finally enters the combustion chamber.

[0018] Burning chamber 7. The high-temperature oxygen-enriched chamber is connected with the oxygen-enriched gas pipe 4, and a high-temperature oxygen-enriched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com