Car bady fittings light weight method based on response surface method

A car body, response surface method technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve the problem of not considering the crashworthiness of the parts structure, and achieve easy parameter changes, controllable precision, and calculation. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

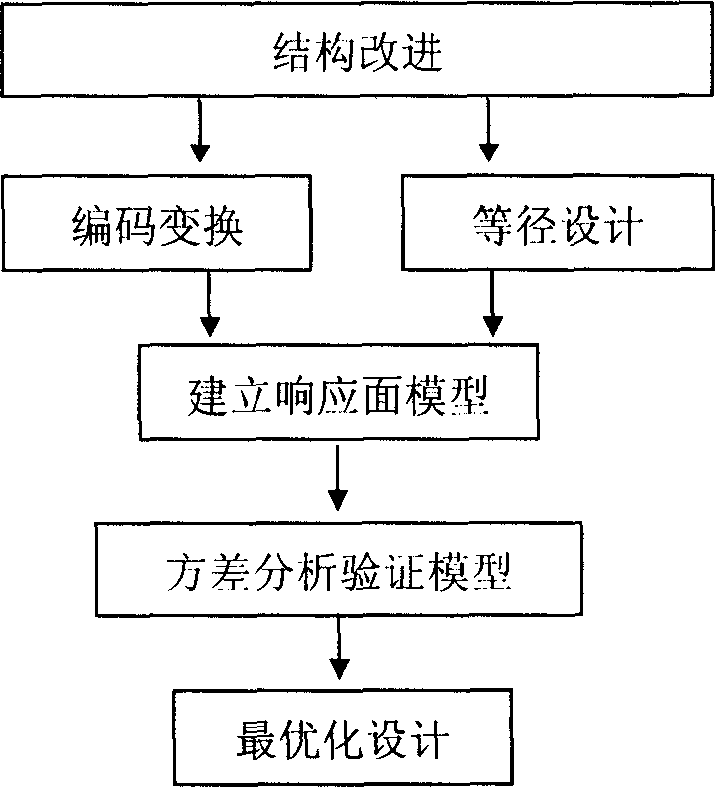

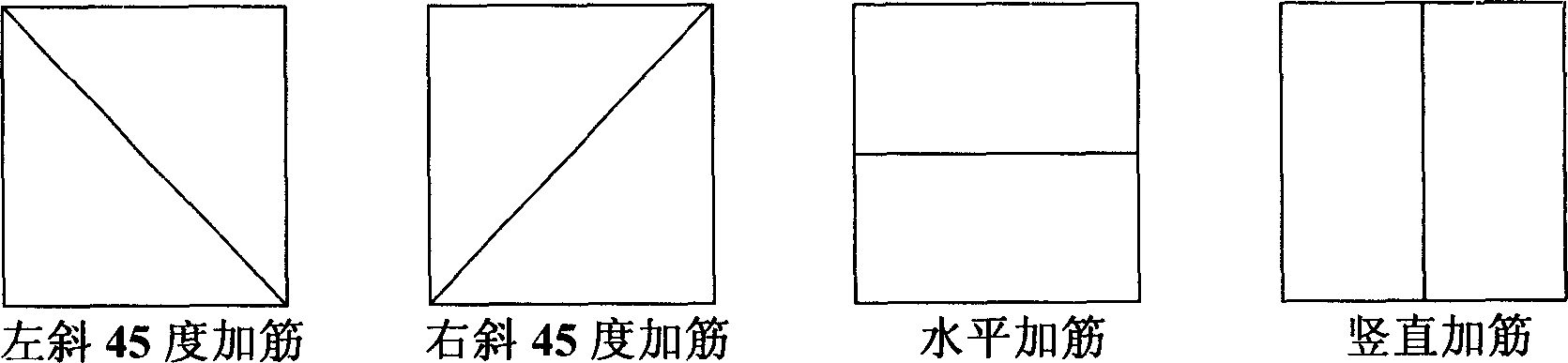

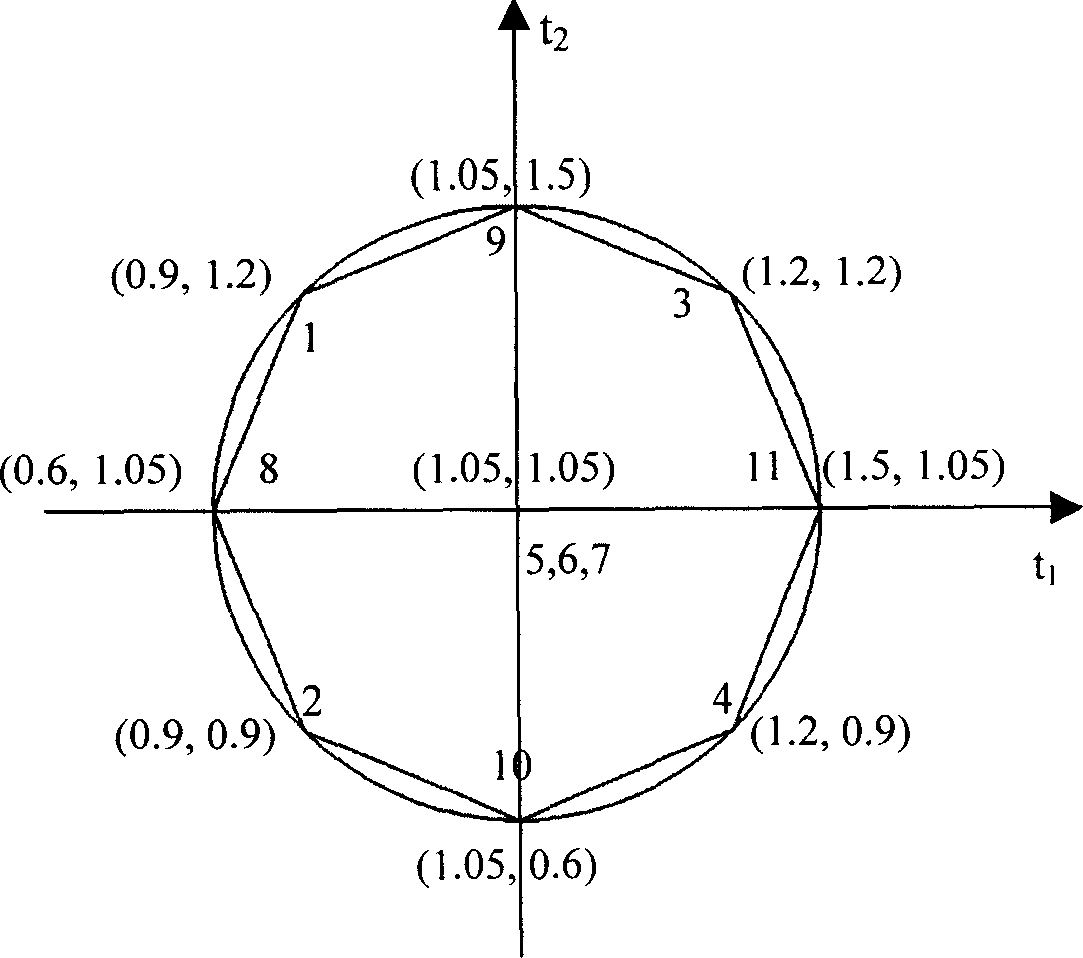

[0024] The present invention first improves the structure of the parts, and then theoretically establishes the mathematical model of the functional relationship between the collision energy absorption and its wall thickness and the linear functional relationship between the mass of the body parts and the wall thickness, and takes the mass of the body parts as the objective function , the original energy absorption is the constraint condition, the optimal solution of the objective function is obtained through optimization, that is, the minimum mass, and the corresponding thickness values of body parts and reinforcement plates in the feasible region are obtained, so that the original crashworthiness can be satisfied Under the premise, the optimal lightweight effect of parts can be achieved. Provide specific embodiments according to the content of the present invention, the following is the lightweight of a certain car left front side member based on the response surface method,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com