Method and device for forming sliced meat, and machine for puncturing meat string

A molding device and a technology for meat slices, which are applied in the direction of processing meat, meat processing equipment, slaughtering, etc., can solve the problems that the meat pieces cannot be matched, the meat skewers cannot be pierced, and the meat pieces are troublesome to handle, which is conducive to sales. It has the same effect as management, improving the utilization rate and quantity of meat pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

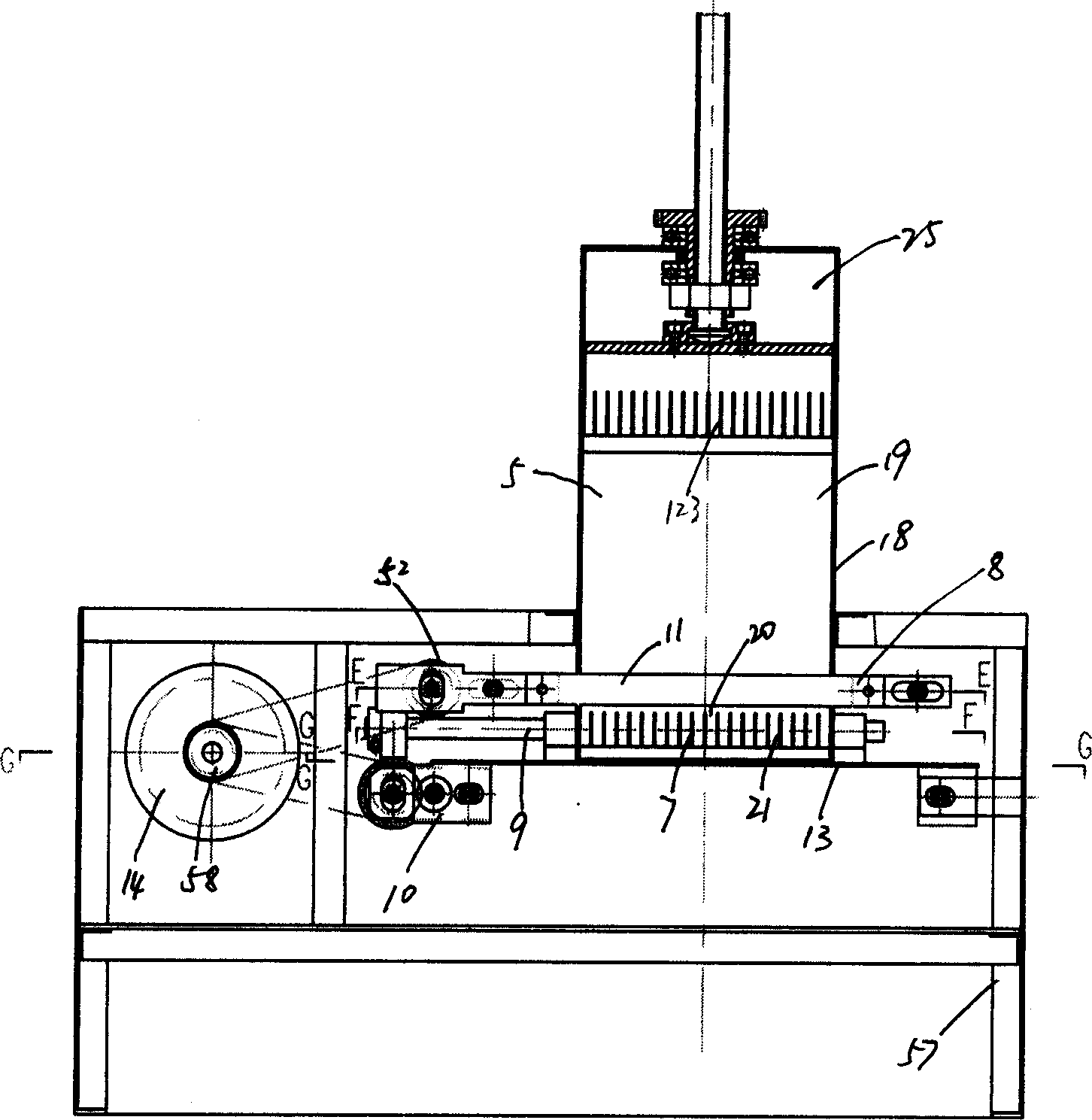

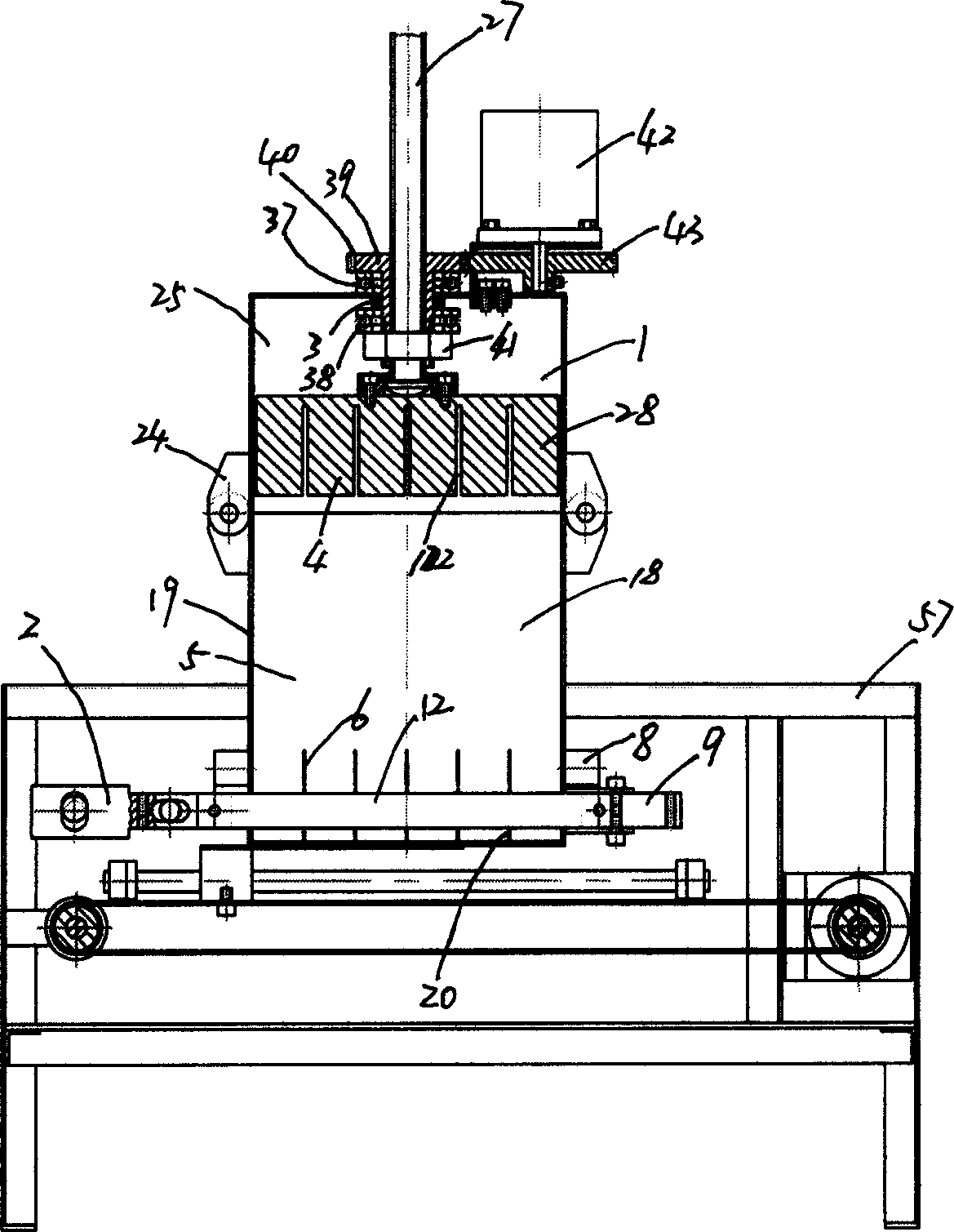

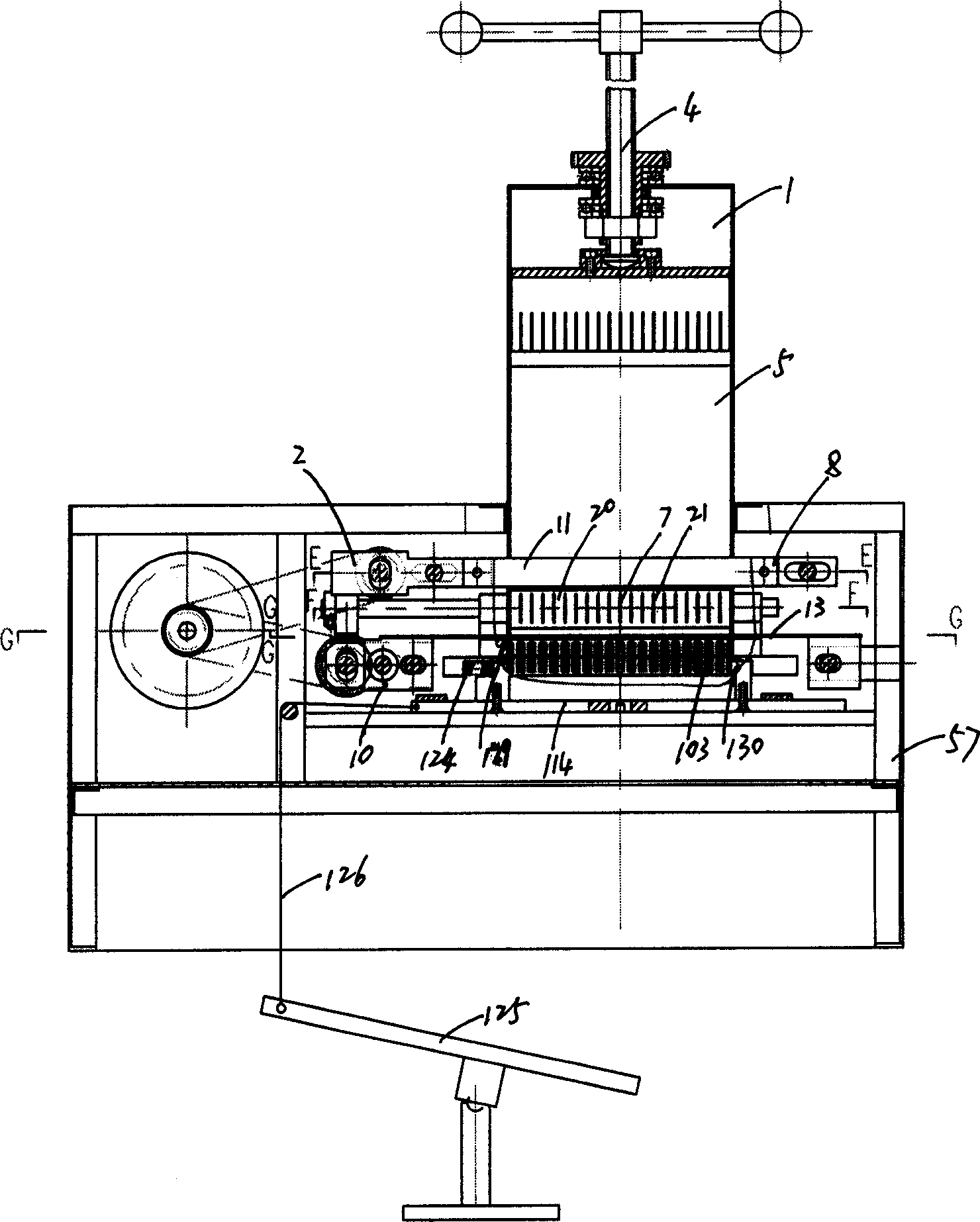

[0035] Such as figure 1 with figure 2As shown, a hopper 5 is installed on the platform of the frame 57, a part of the hopper 5 is above the platform of the frame 57, and the other part is under the platform of the frame 57, and the hopper 5 is evenly provided with a discharge hole bottom plate. The hopper has a bar-shaped groove one 6 and a bar-shaped groove two 7 symmetrically respectively at the bottom of the left and right sides 18 and the front and rear sides 19 of the hopper 5; a hopper cover 25 is connected by a hinge 24 on the top of the hopper 5. The hopper cover 25 can be easily opened and covered from one side, and a plane thrust bearing 37 is set above the hopper cover 25, and a centripetal bearing 3 and a plane thrust bearing 38 are arranged successively at the lower end of the hopper cover 25. A nut 39 is set in the thrust bearing 37, the radial bearing 3 and the plane thrust bearing 38, and the upper end of the nut 39 is set as a running wheel or a running whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com