Mixing member for blenders

A technology of mixing components and agitators, which is applied to mixers with rotating stirring devices, mixers, applications, etc., can solve the problems of difficult cleaning and poor operation of mixing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

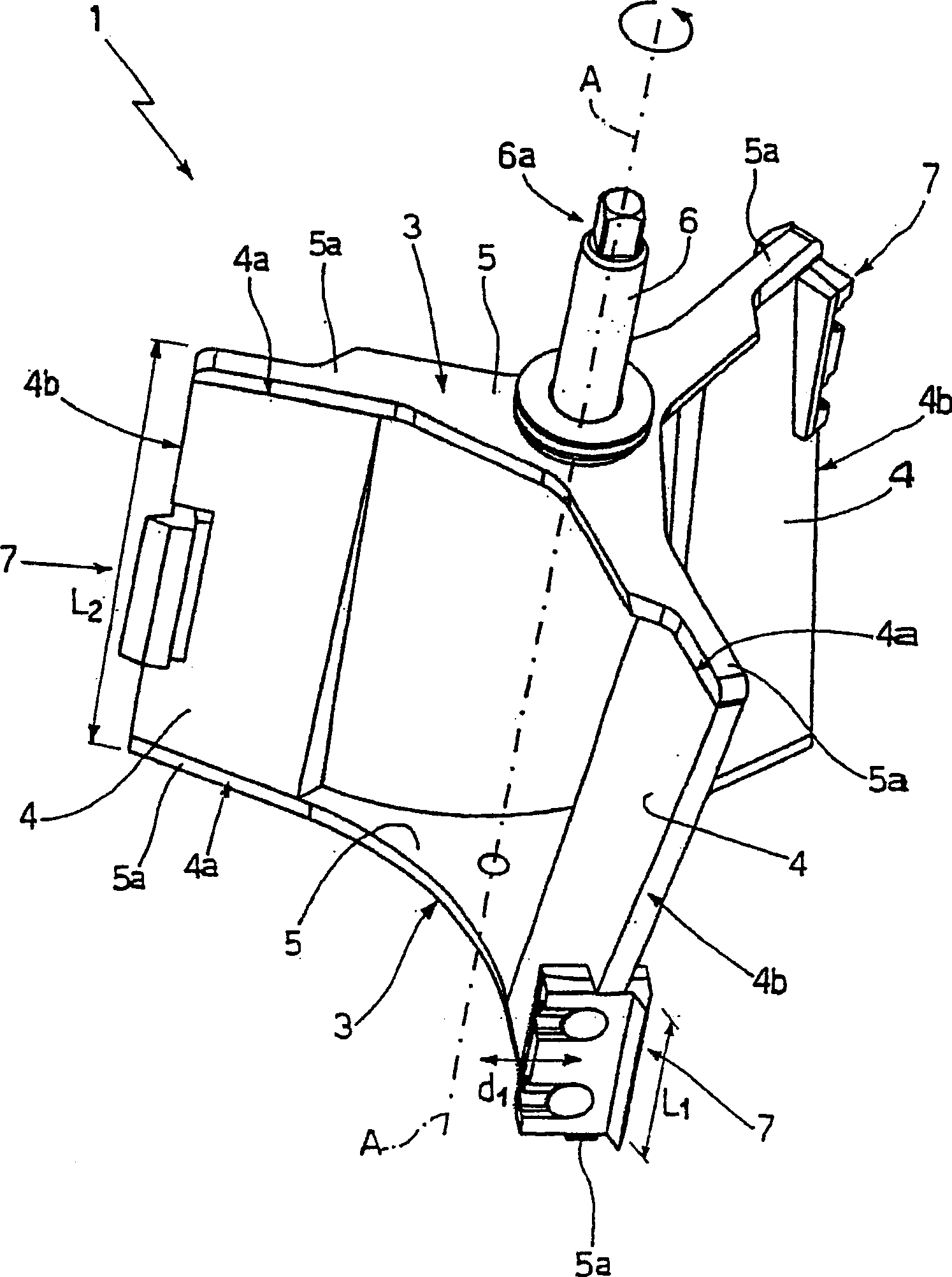

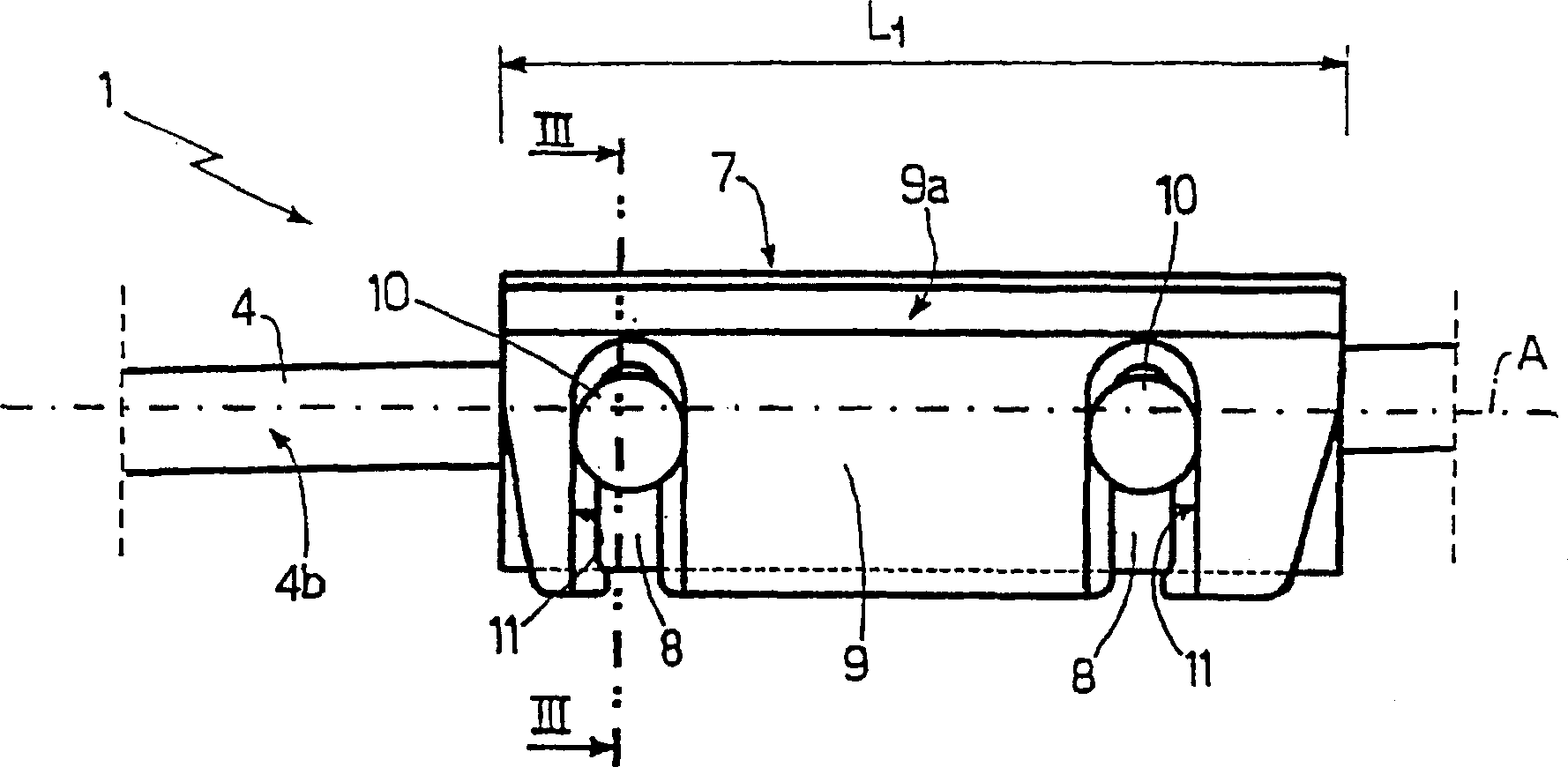

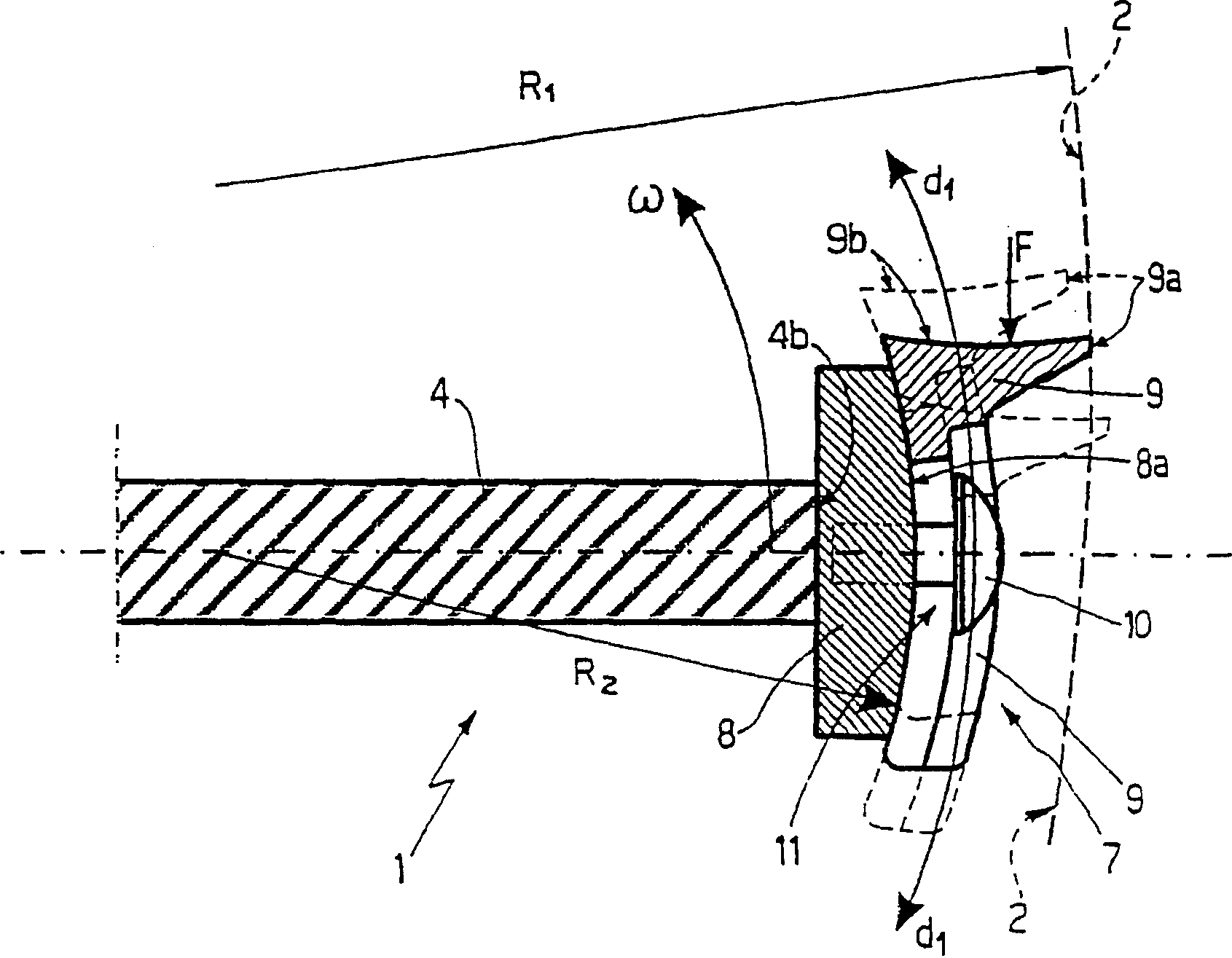

[0015] benchmark figure 1 , figure 2 and image 3 , the reference number 1 designates as a whole a rotating mixing member mounted for axial rotation within a container 2 of a known stirrer, wherein the container 2 is substantially cylindrical and the inner cylindrical surface has a radius of curvature R 1 Preferably, although not necessarily, it is in the range of 10 to 20 centimeters.

[0016] benchmark figure 1 , the mixing member 1 extends coaxially with a longitudinal axis A which in use coincides with the longitudinal axis of symmetry (not shown) of the container 2, the mixing member 1 comprising: coaxial with the longitudinal axis A and spaced a given distance apart two supporting hubs 3; and a plurality of longitudinal blades 4 extending from one hub 3 to the other and generally parallel to the longitudinal axis A of the mixing member 1 and angularly spaced about the longitudinal axis A To form a "squirrel cage" structure which is bounded laterally by a cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com