Energy saving equipment of double effect rectification for methanol, and method

A technology of double-effect rectification and energy-saving equipment, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as reflux pump not operating normally, increasing load of atmospheric tower, cavitation, etc. Achieve the effects of improving product quality and equipment use efficiency, reducing the possibility of cavitation, and improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

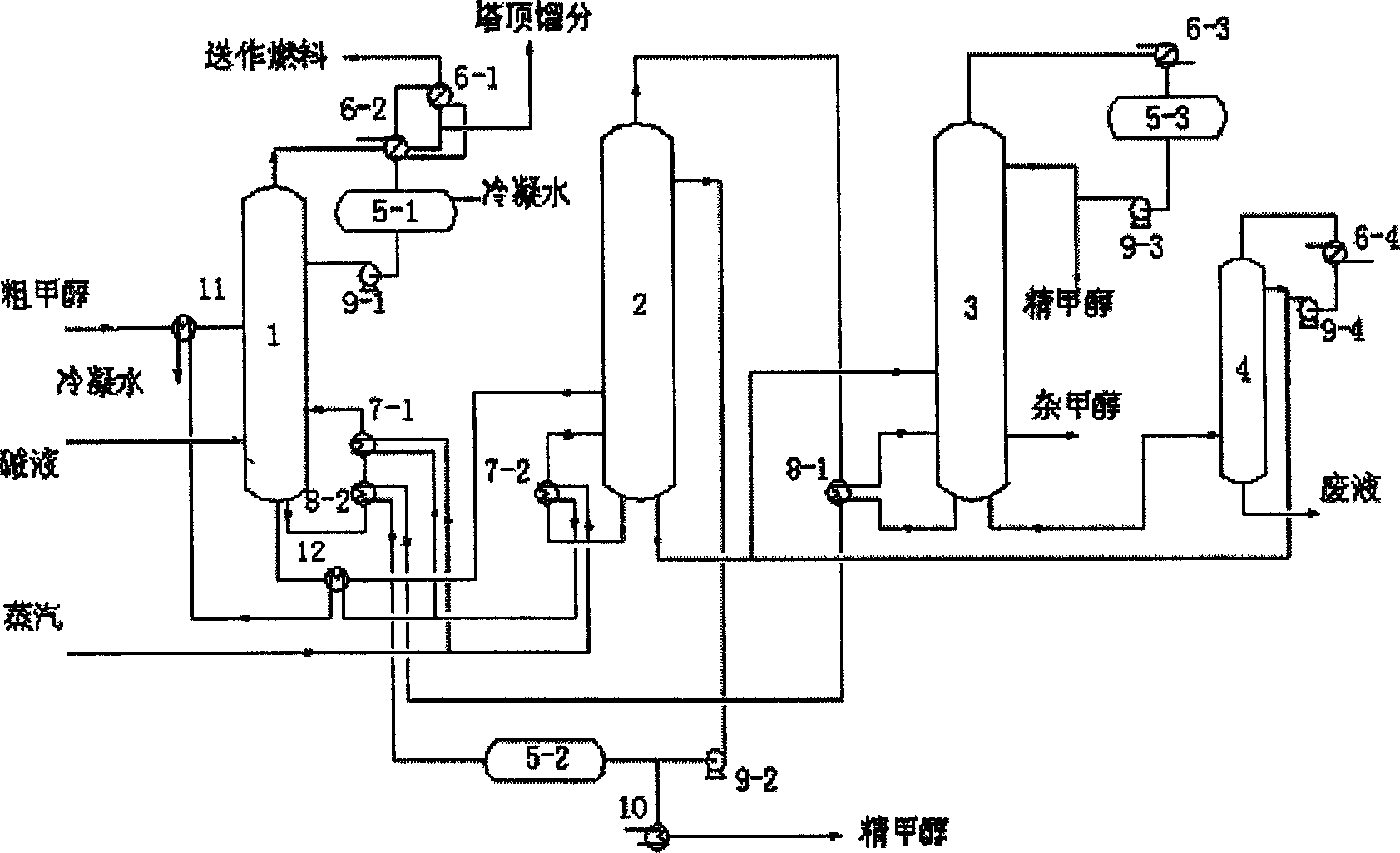

[0027] Below in conjunction with accompanying drawing 1, equipment and method of the present invention are further described, and concrete process is as shown in Figure 1:

[0028] 1. Crude methanol enters the middle and upper part of the pre-distillation tower (1) after the raw material preheater (11) exchanges heat with the steam condensate water of the reboiler of each tower. The vapor at the top of the pre-rectification column is partially condensed in the primary condenser (6-2), and the temperature of the condenser is controlled at 60-70°C. The non-condensable gas of the primary condenser enters the secondary condenser (6-1) and is cooled to 38-40°C, the non-condensable gas of the secondary condenser is sent as fuel, and the condensate passes through the return tank of the primary condenser (5-1) , returned to the top of the pre-rectification column by the reflux pump (9-1). The process extraction water is added into the secondary condenser or the primary condenser or i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com