Method for cooling power transformer and cooling device

A technology of power transformer and cooling method, which is applied in the direction of transformer/inductor cooling, etc., which can solve the problems of large water consumption, stop production and cleaning, and high operating cost, and achieve the effect of eliminating power accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

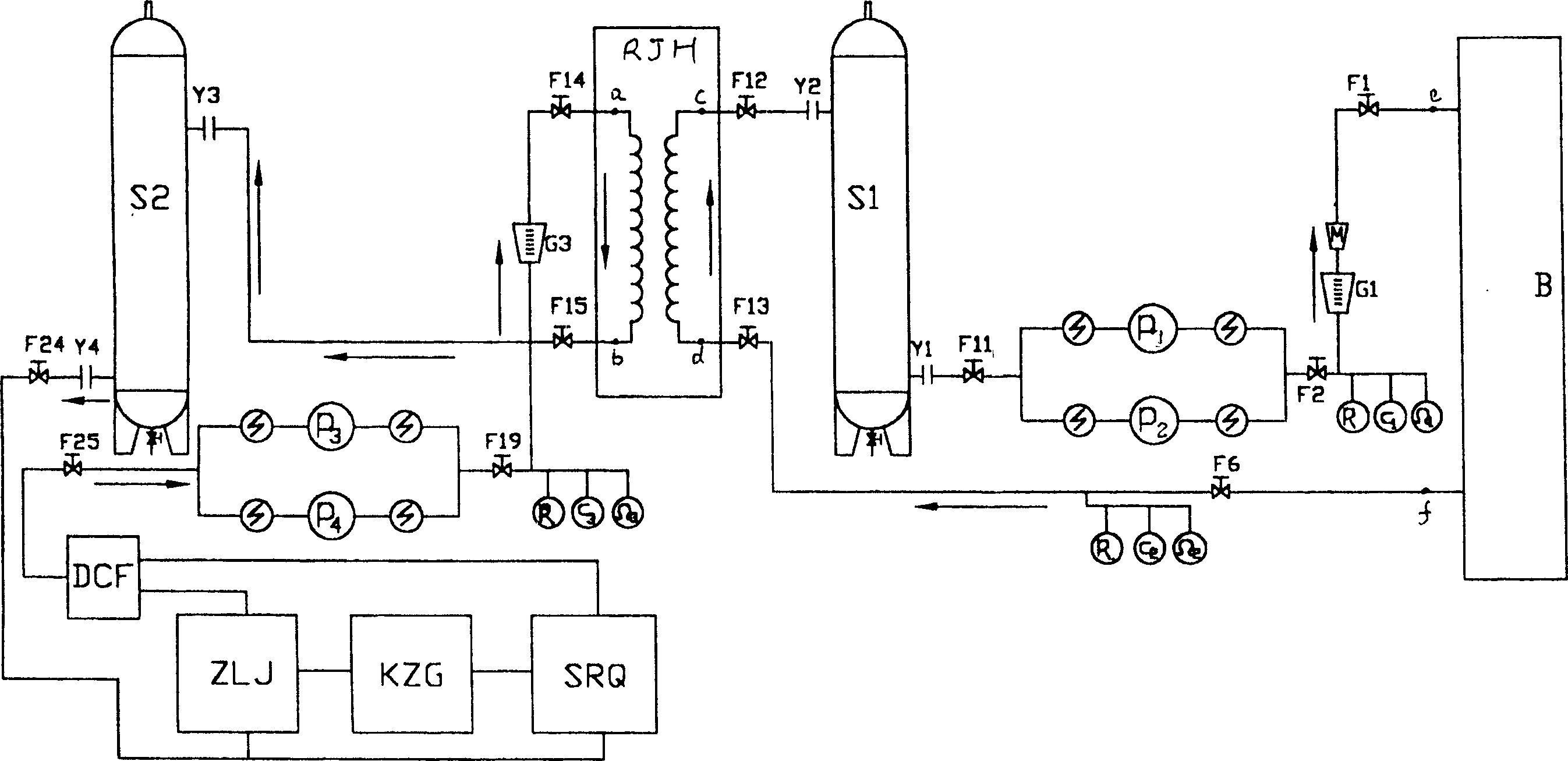

[0013] For a certain type of power transformer, it is first necessary to find out the type of transformer oil in it, or measure its quality parameters, and then select the same transformer oil or transformer oil with the same quality parameters to inject into expansion tanks S1 and S2; The two ports are connected with the oil outlet f and the oil inlet e of the transformer B, the oil pumps P1 and P3 are started, and the cooling device starts to work.

[0014] Embodiment The cooling device includes a commercially available heat exchanger RJH, in which the hot oil passage (connected in series with the closed circulation loop I) is isolated from the surrounding cold oil passage (connected in series with the closed circulation loop II). The oil inlet d of the hot end of the heat exchanger RJH is connected to the oil outlet f of the transformer B, and the oil outlet c is connected to the upper oil inlet of the low-pressure expansion tank S1, and the sensor Y2 and the valve F12 compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com