Hydrocracking method for composite catalyst bed layer

A composite catalyst, hydrocracking technology, used in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

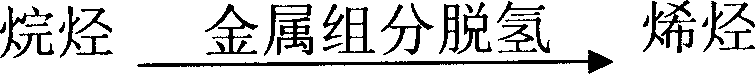

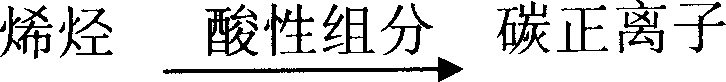

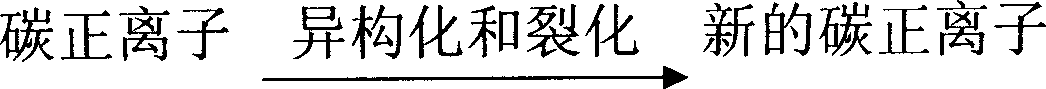

Problems solved by technology

Method used

Image

Examples

example 1

[0027] This scheme belongs to a one-stage series process flow, which can be applied to existing conventional industrial devices without investing in the modification of the reaction system. Two reactors in series are used, the first reactor (R1) uses a hydrorefining catalyst, the second reactor (R2) uses a hydroupgrading catalyst and a hydrocracking catalyst, and the two reactors are used in series and share a Set of circulating hydrogen system. Catalyst loading scheme:

[0028] The hydrofining catalyst is 3996 hydrofining catalyst developed by Fushun Petrochemical Research Institute and produced by Fushun Petrochemical Company Catalyst Factory. The hydrocracking catalyst was the 3974 catalyst produced by Fushun Petrochemical Company Catalyst Factory developed by Fushun Petrochemical Research Institute. The main properties of each catalyst are shown in Table 1.

[0029] catalyst

[0030] The operating conditions of this process scheme: reaction pressure 15MPa, hydr...

example 2

[0035] The hydrogenation upgrading catalyst in Example 1 was mixed with 20V% hydrocracking catalyst, installed in the upper layer of the cracking reactor, and the remaining cracking catalysts were installed in the lower layer, and the operating space velocity was changed. The results are shown in Table 2.

example 3

[0037]The hydrogenation upgrading catalyst in Example 2 was mixed with 60V% hydrocracking catalyst, installed in the upper layer of the cracking reactor, and the remaining cracking catalysts were installed in the lower layer, and the operating space velocity was changed. The results are shown in Table 2.

[0038] Program

[0039] From the data, it can be seen that compared with the traditional positive sequence process, the process of the present invention, due to the use of the catalyst process involved in the present invention and its use scheme, compared with the comparative example, due to the hydrogenation modification, additional intermediate products are produced, which improves the conventional hydrogenation process. The degree of difficulty of carrying out the cracking process has accelerated the reaction speed, so although the scheme of the present invention is used under high space velocity or handles more materials per unit time (modifying and cracking to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com