Environment-friendly energy-saving stepless speed changing engine

An environmentally friendly, energy-saving, continuously variable speed technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of engine noise, increased vibration, increased engine braking force, shortened engine life, etc., to reduce noise and vibration, Effect of increasing centrifugal force and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

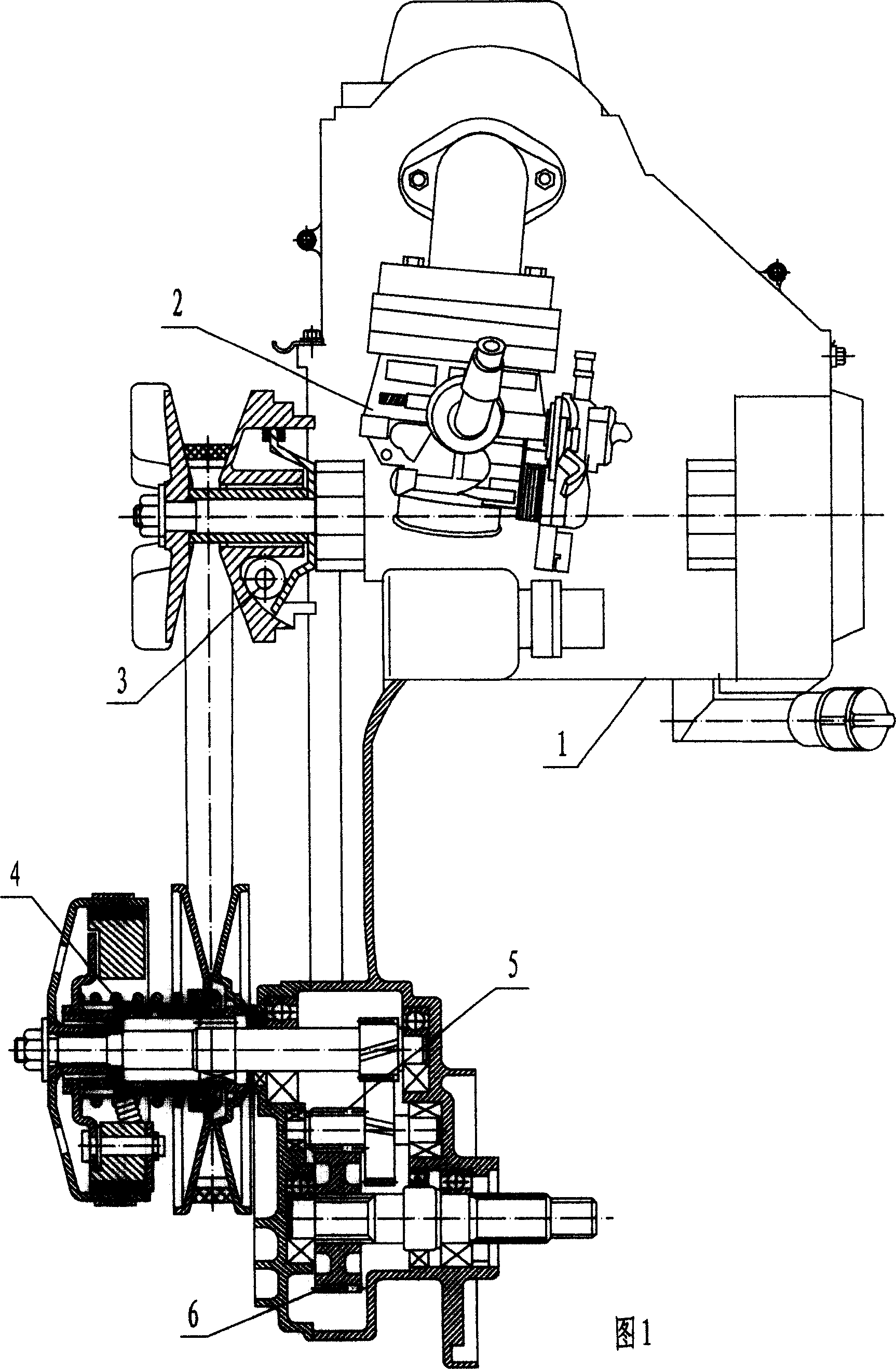

[0009] The present invention is further described below in conjunction with accompanying drawing:

[0010] Referring to Figure 1, the carburetor 2 is converted from the original flat-suction vacuum film plunger carburetor to a flat-suction plunger carburetor; the weight of the centrifugal roller 3 of the driving wheel of the CVT is changed from the original 12±1 The gram weight is 18±2 grams, and the parameters of the driven wheel compression spring 4 of the CVT are changed (it includes: the number of coils of the spring, pitch, height and its compression force); the distance between the gears in the reduction box is reduced Speed ratio, and increase the intermediate shaft gear 5 of the reduction box from the original 13 teeth to 16 teeth, and reduce the final gear 6 from the original 40 teeth to 37 teeth, and retain the gears of the original reduction box The center distance, modulus and total number of teeth remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com