Control unit for contact screen

A control unit, touch screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problem of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

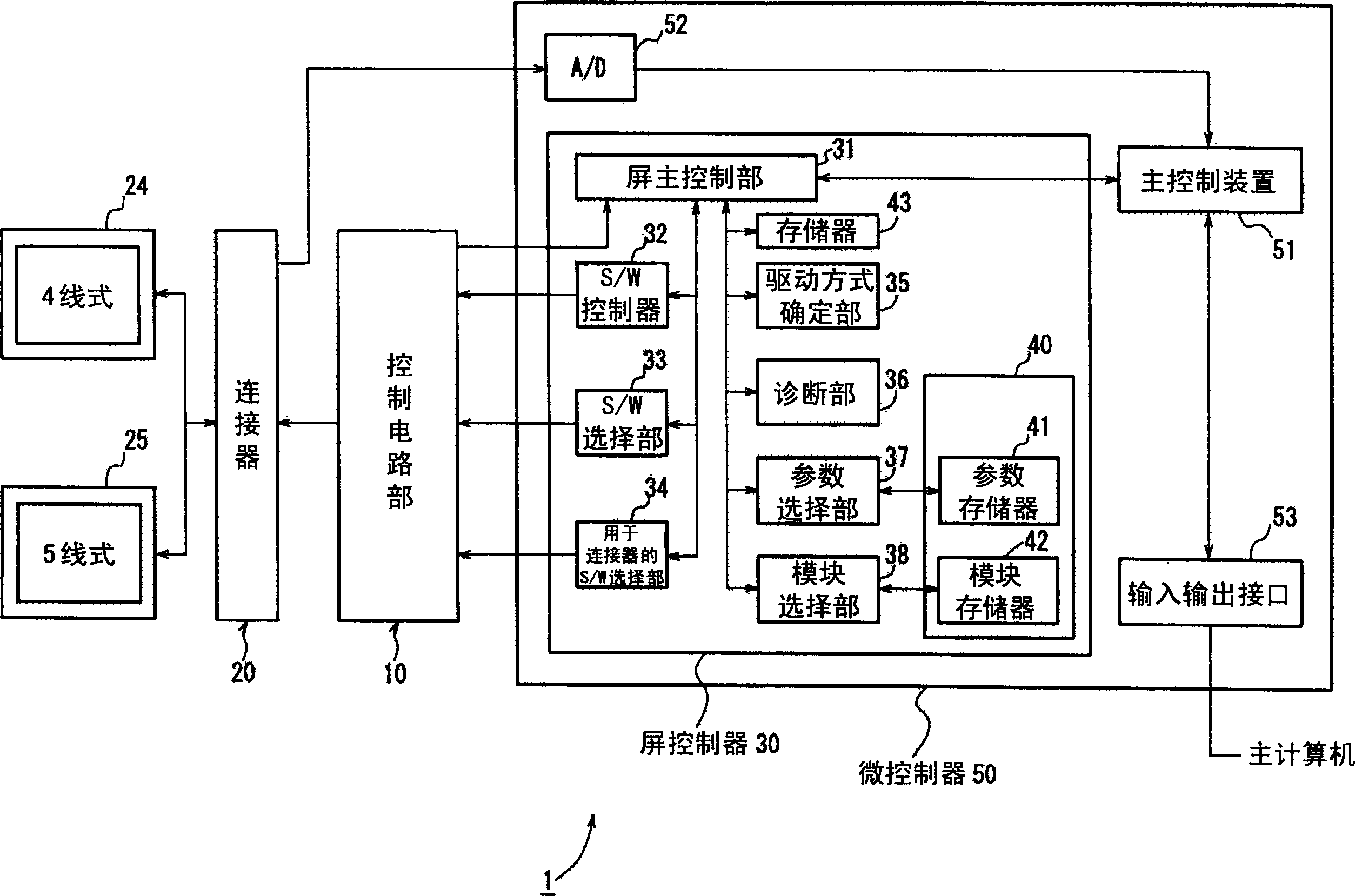

[0028] Next, components of the present invention will be described.

[0029] (touch screen)

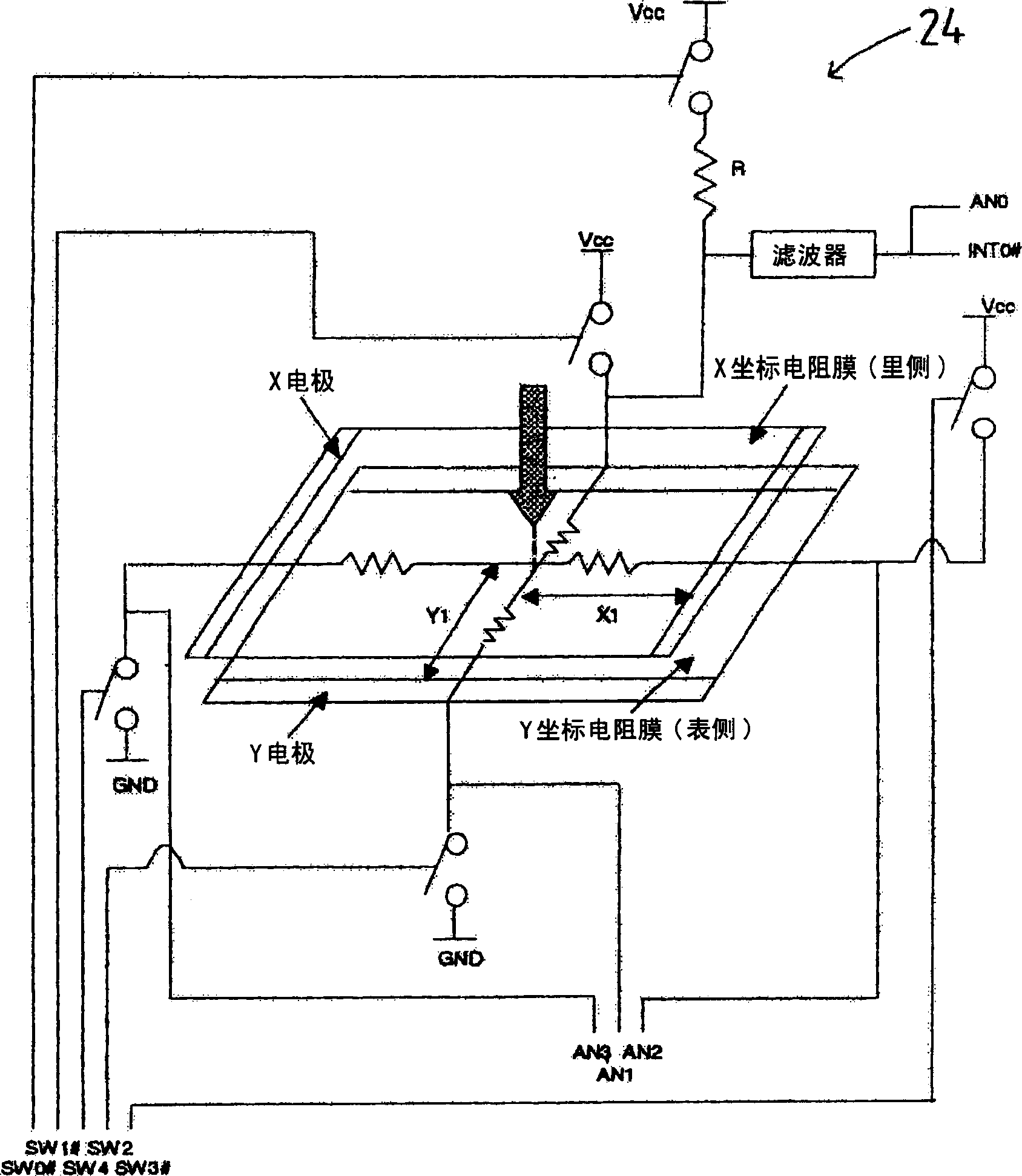

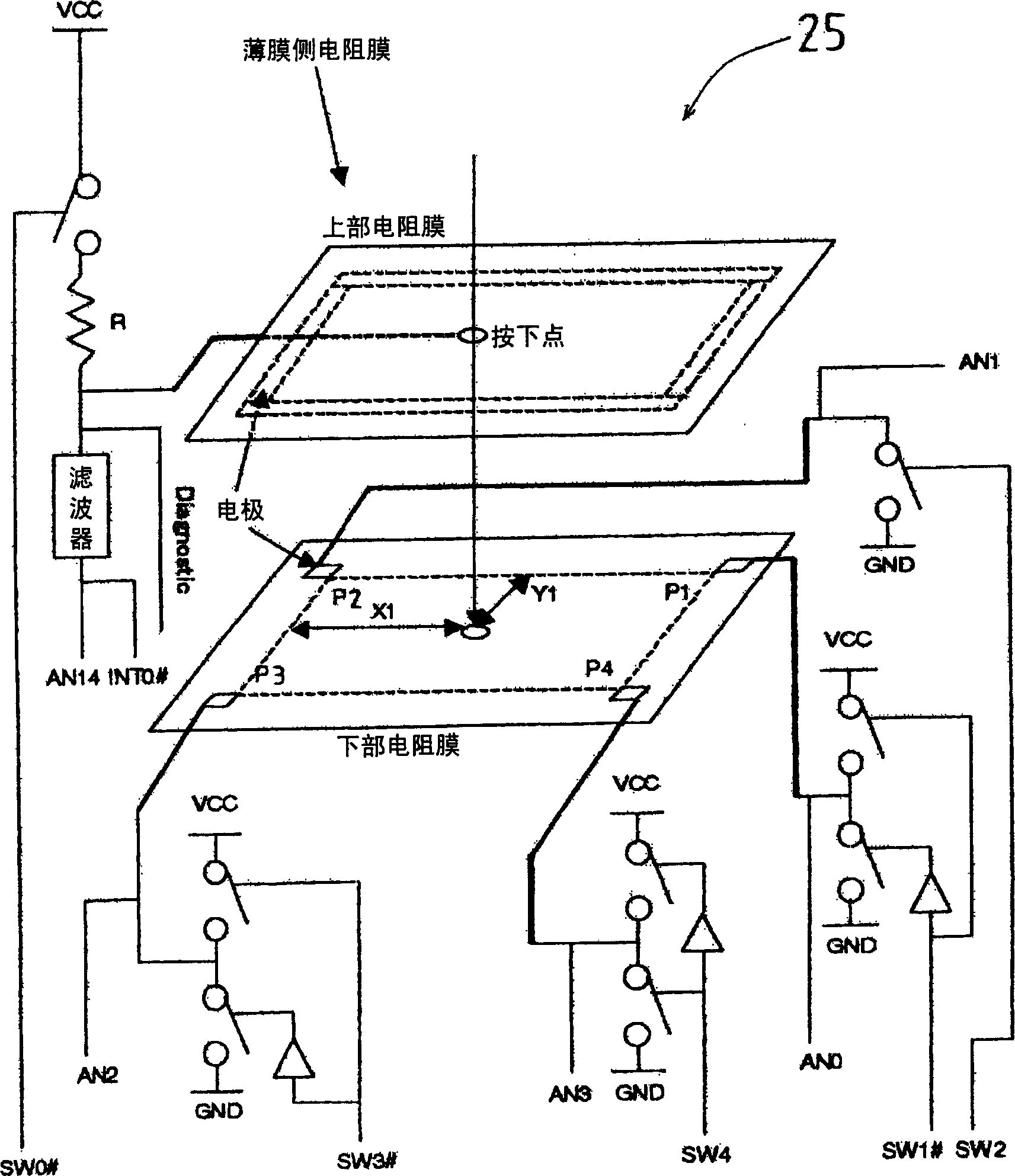

[0030] Since the resistive film driving method targeted by the present invention is roughly divided into touch screens, it has been proposed to be divided into a 4-wire resistive film method (hereinafter referred to as "4-wire type") and a 5-wire resistive film method (hereinafter referred to as "5-wire type"). Mode"). The characteristic of the 4-wire resistive film method is accurate positional accuracy. On the other hand, the characteristic of the 5-wire resistive film method is high durability. Therefore, the user can arbitrarily select a driving method in consideration of this characteristic. An 8-wire resistive film method is also known as a method using the same operating principle as the 4-wire method. The 8-wire resistive film system is also treated in the same manner as the 4-wire system in this specification.

[0031] (control circuit part)

[0032] The control circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com