Layered ordered ultramicroporous material and synthesis method thereof

A synthesis method and ultra-microporous technology, applied in the directions of silicon dioxide, silicon oxide, etc., can solve the problem of difficulty in synthesizing layered ordered ultra-microporous materials, and achieve the effects of stable structure, easy control of conditions, and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

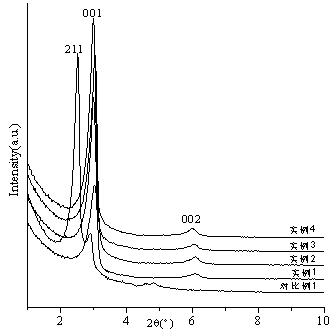

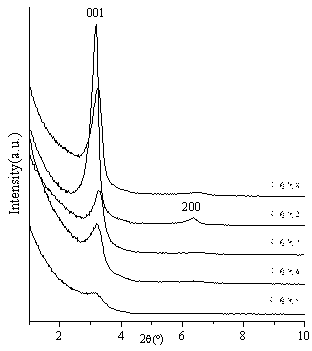

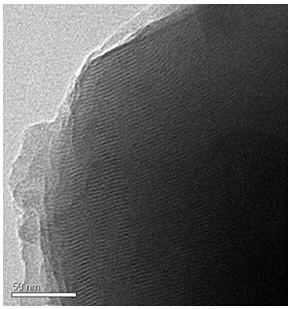

[0023] At 35°C, dissolve dehydroabietylamine (DHAA) and cetyltrimethylammonium bromide (CTAB) in deionized water, stir well, then add sodium hydroxide to adjust the pH value, under stirring conditions Add silicon source tetraethyl orthosilicate dropwise, wherein the molar ratio of silicon source tetraethyl orthosilicate, cetyltrimethylammonium bromide, dehydroabietylamine, and sodium hydroxide is 1:0.114:0.00286: 0.5, continue to stir for 2 h, then transfer to a hydrothermal reaction kettle, crystallize at 100°C for 72 h, wash, filter, and dry to obtain silica powder.

Embodiment 2

[0025] It is basically the same as Example 1, except that the molar ratio of the silicon source tetraethyl orthosilicate, cetyltrimethylammonium bromide, dehydroabietylamine, and sodium hydroxide is 1:0.114: 0.00457:0.5.

Embodiment 3

[0027] It is basically the same as Example 1, except that the molar ratio of the silicon source tetraethyl orthosilicate, cetyltrimethylammonium bromide, dehydroabietylamine, and sodium hydroxide is 1:0.114: 0.00714:0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com