Wearing layer-possessing mould core and its preparation method

A technology of wear-resistant layer and mold core, which is applied in glass pressing, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of short service life and poor wear resistance of mold core, so as to prolong service life and increase repetition The number of times of molding and the effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings.

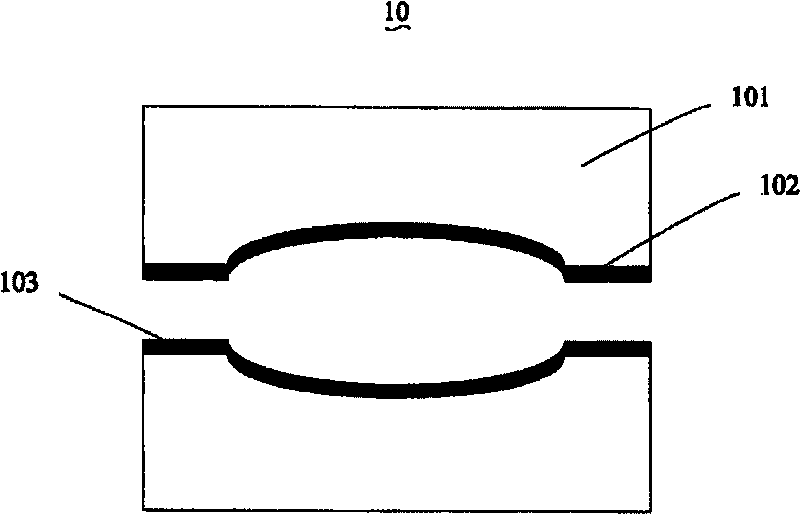

[0037] see figure 1 , the present invention provides a mold core 10 for molding aspheric optical glass products, which includes a mold core base 101 and a wear-resistant layer 103 formed on the molding surface 102 of the mold core base 101 . The thickness of the wear-resistant layer 103 is in the range of 20 nm to 200 nm.

[0038] The mold core base 101 can be manufactured by sintering the following ceramics, cermets or superhard alloys as main materials: SiC, Si, Si 3 N 4 , ZrO 2 、Al 2 o 3 , TiN, TiO 2 , TiC, B 4 C, WC, W or WC-Co.

[0039] The wear-resistant layer material 103 includes SiC, WC, Si 3 N 4 , TiN, BCN, Pt, Ir, Os, Re, Rh, and Pd.

[0040] Preferably, the thickness of the wear-resistant layer is in the range of 50 nm to 100 nm.

[0041] The molding surface 102 of the mold core base 101 needs to correspond to the shape of the aspheric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com