White light LED package radiating structure

A technology of LED packaging and heat dissipation structure, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve the problems of heat accumulation, high heat generation of lamps, short life of white LEDs, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

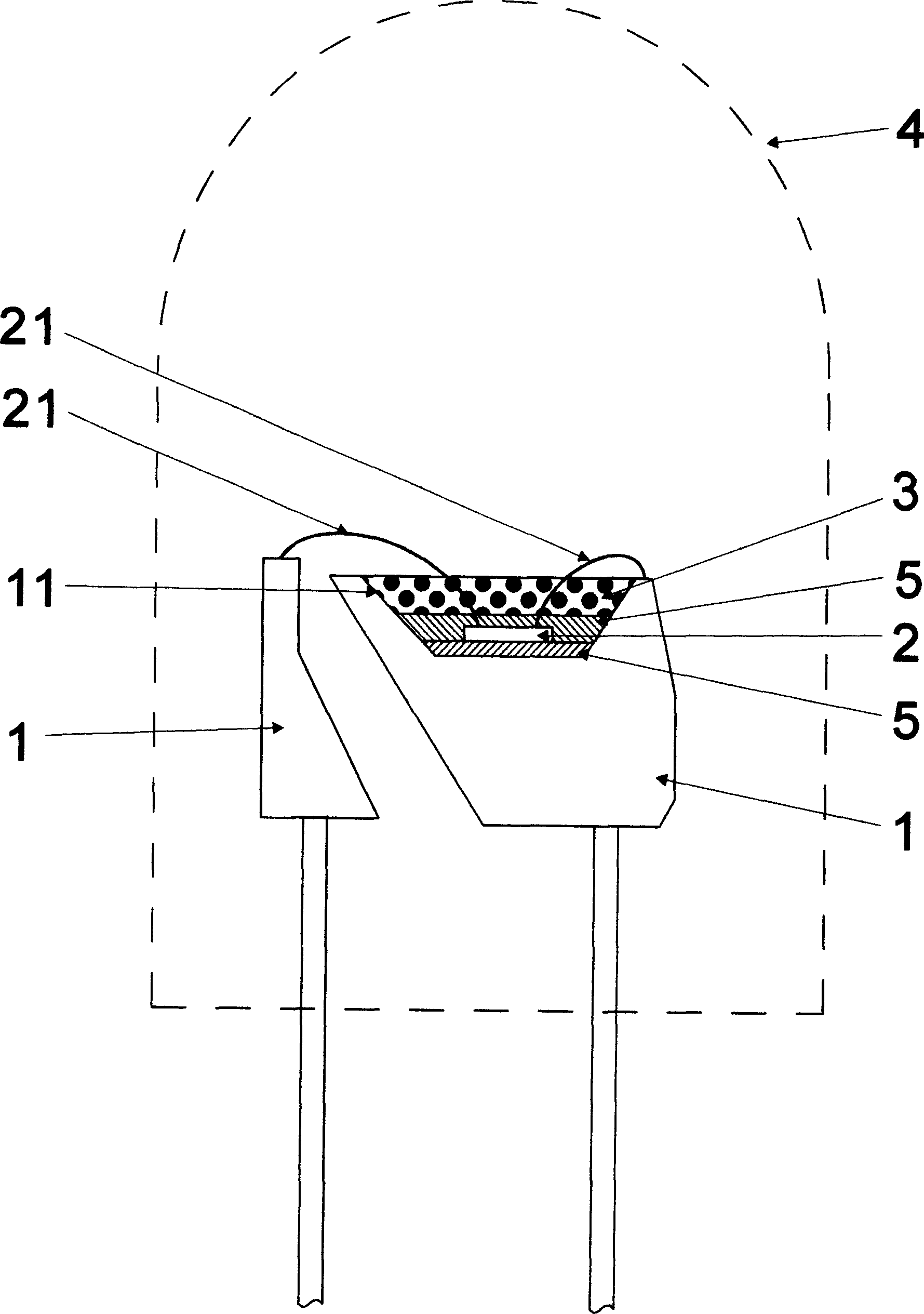

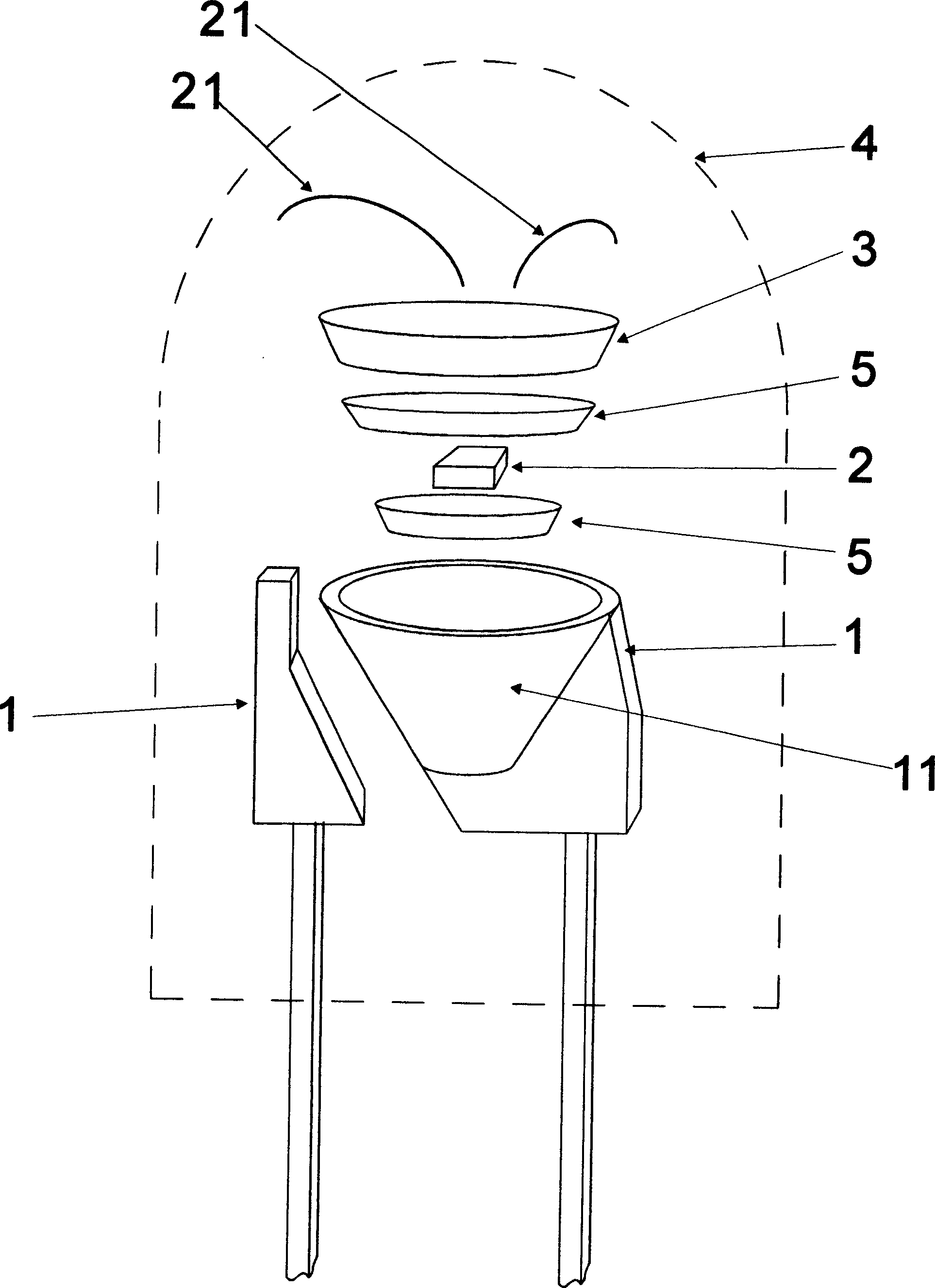

[0014] Such as figure 1 , figure 2 As shown, the heat conduction and heat dissipation structure of the white light LED package according to the present invention has two metal lead frames 1, the upper end of one lead frame is a support cup 11, and a blue light-emitting crystal 2 and fluorescent powder glue are arranged in the cup. Layer 3, the blue light-emitting crystal 2 leads two wires 21 to be connected to the two lead frames 1 respectively; the upper and lower sides of the blue light-emitting crystal are respectively provided with a conductive heat-dissipating glue layer 5, and the two conductive heat-dissipating glue layers 5 connect the blue light-emitting crystal 2 The encapsulation, and the fluorescent powder adhesive layer 3 are arranged on the upper conductive thermal adhesive layer. The upper end of the two-lead frame is encapsulated with a colorless and transparent resin 4 .

[0015] The packaging process steps of the present invention are as follows: first inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com