Expandable injection bolt and grouting method using same

A technology of bolts and expansion parts, which is applied in the field of grouting using the bolts, can solve problems such as poor reinforcement effect and insufficient fixing force, and achieve the effects of good pouring workability, loosening suppression, and leakage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, the present invention will be described with reference to the drawings.

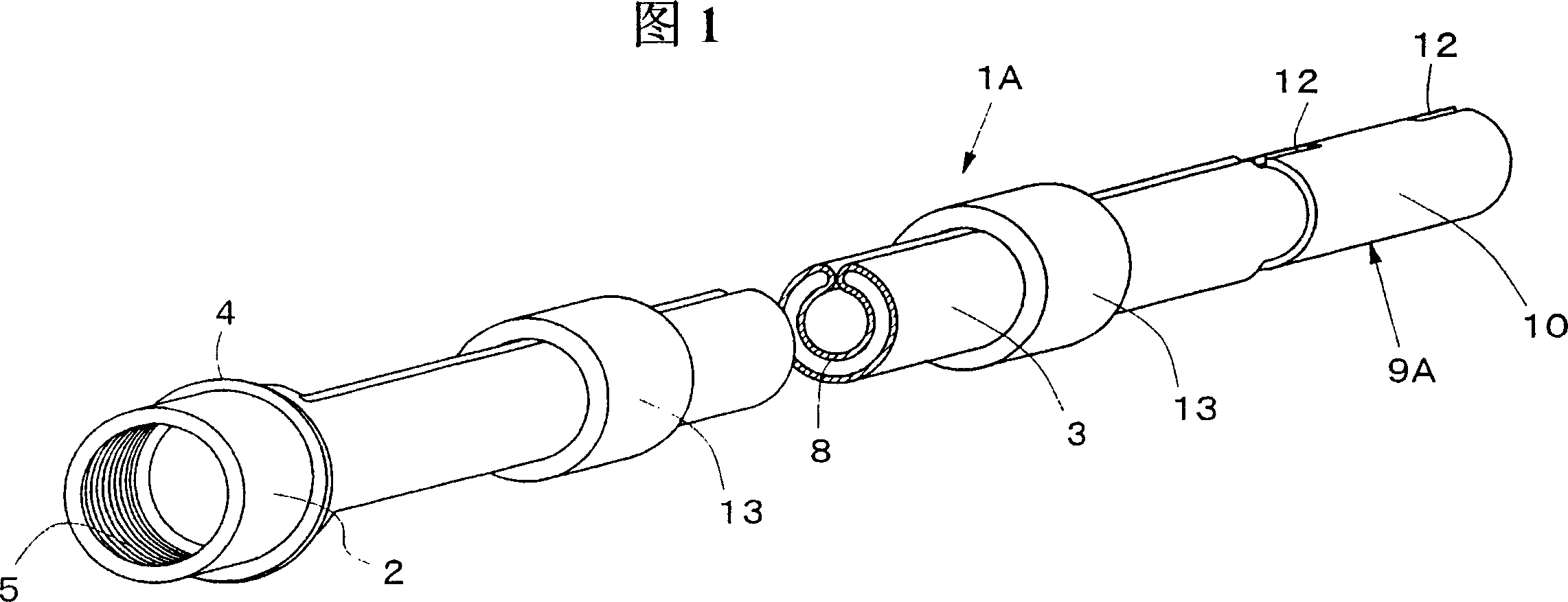

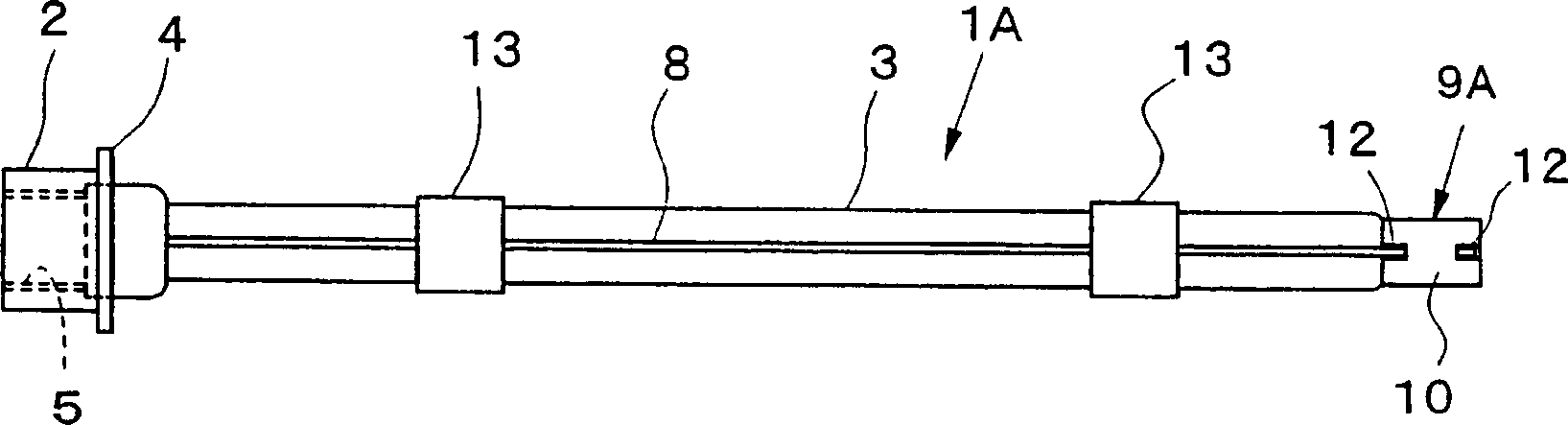

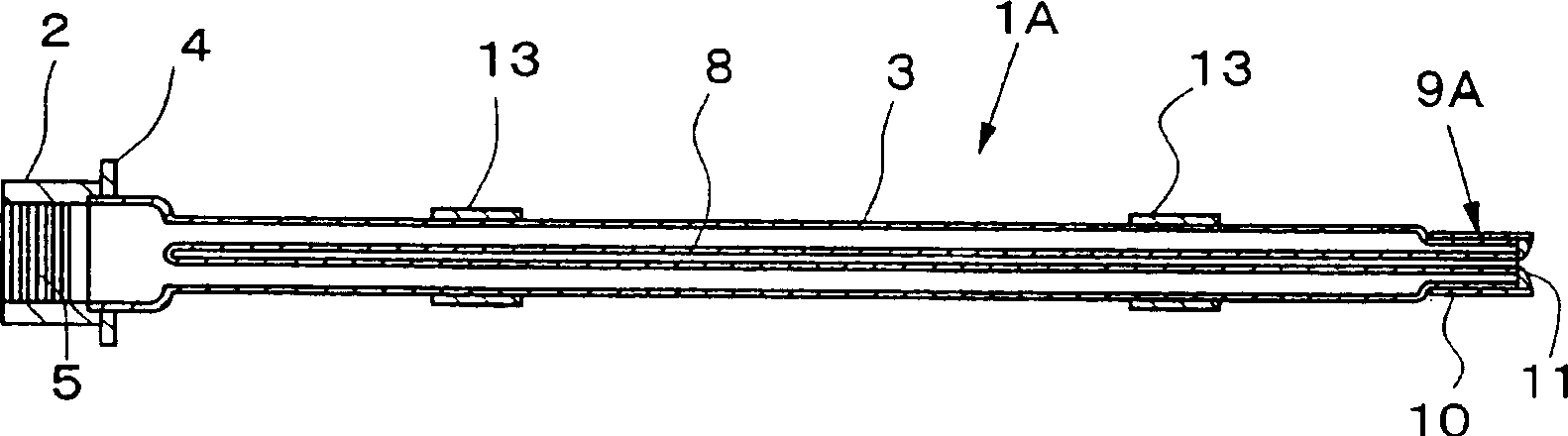

[0048] Fig. 1 is a perspective view showing the first embodiment of the expansion grouting bolt of the present invention, the middle part is omitted, figure 2 It is a top view of the expansion grouting bolt shown in Figure 1, image 3 is a cross-sectional view of the expansion grouting bolt shown in Figure 1, Figure 4A and 4B It is an enlarged sectional view and an enlarged front view of the front end portion of the expansion grouting bolt shown in FIG. 1 .

[0049] Figure 1~ image 3 As shown, the expansion grouting bolt 1A of this embodiment is formed into a tubular shape provided with an inlet sleeve 2 (mouth sleeve) provided at the rear end and an expansion part 3 integrally connected to the front of the inlet sleeve 2, and is configured to be able to pass through the inlet sleeve. 2 Apply internal pressure.

[0050] The inlet sleeve 2 is in the shape of a circular tube that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com