Drum type washing and drying machine

A washing and drying machine, drum-type technology, applied in the direction of household clothes dryer, washing machine with container, washing device, etc., can solve the problems of odor, soaking heating unit, reliability decline, etc., to prevent odor and ensure reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, an embodiment of the present invention will be described in detail with reference to the accompanying drawings. It should be noted that such embodiments do not limit the present invention.

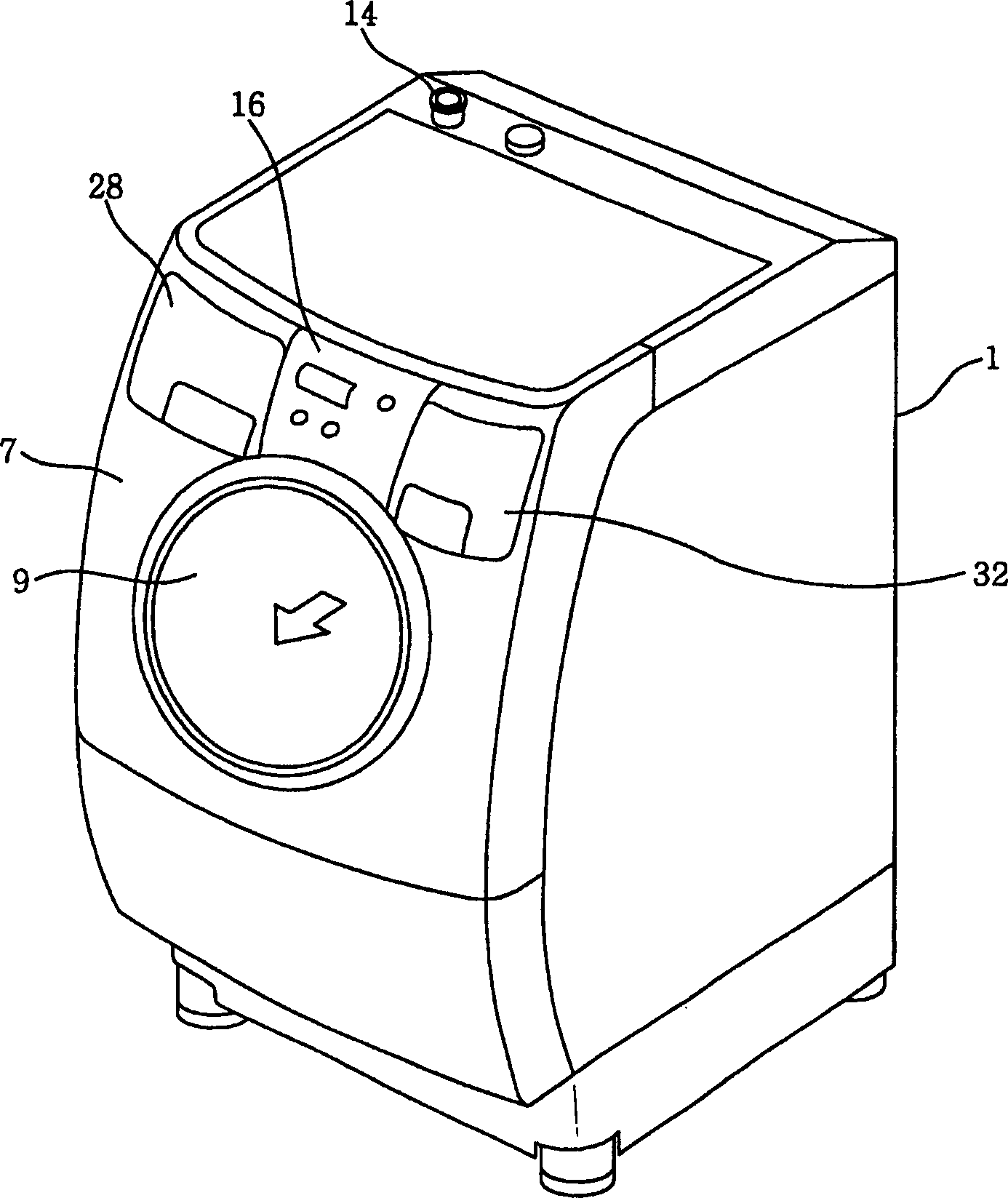

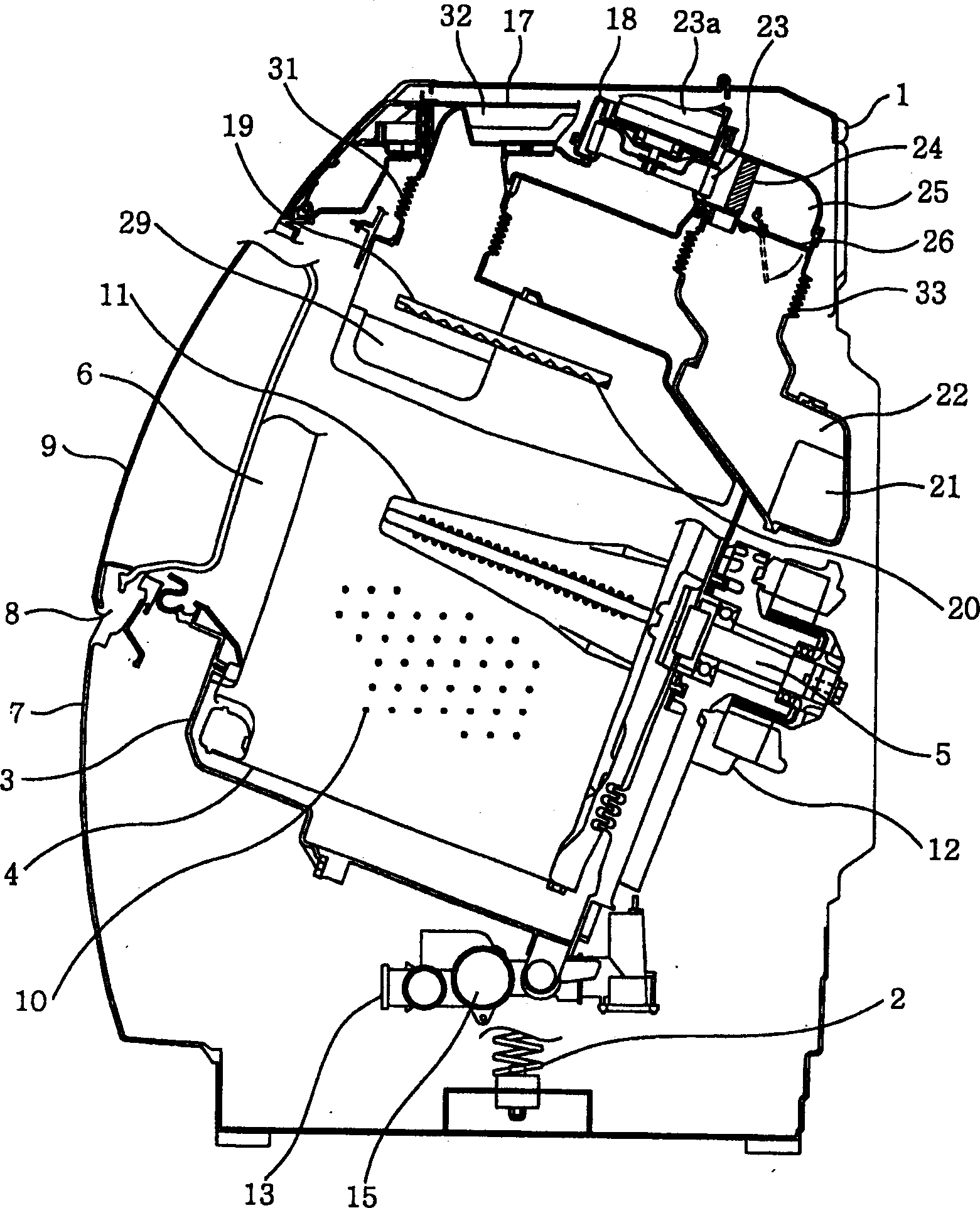

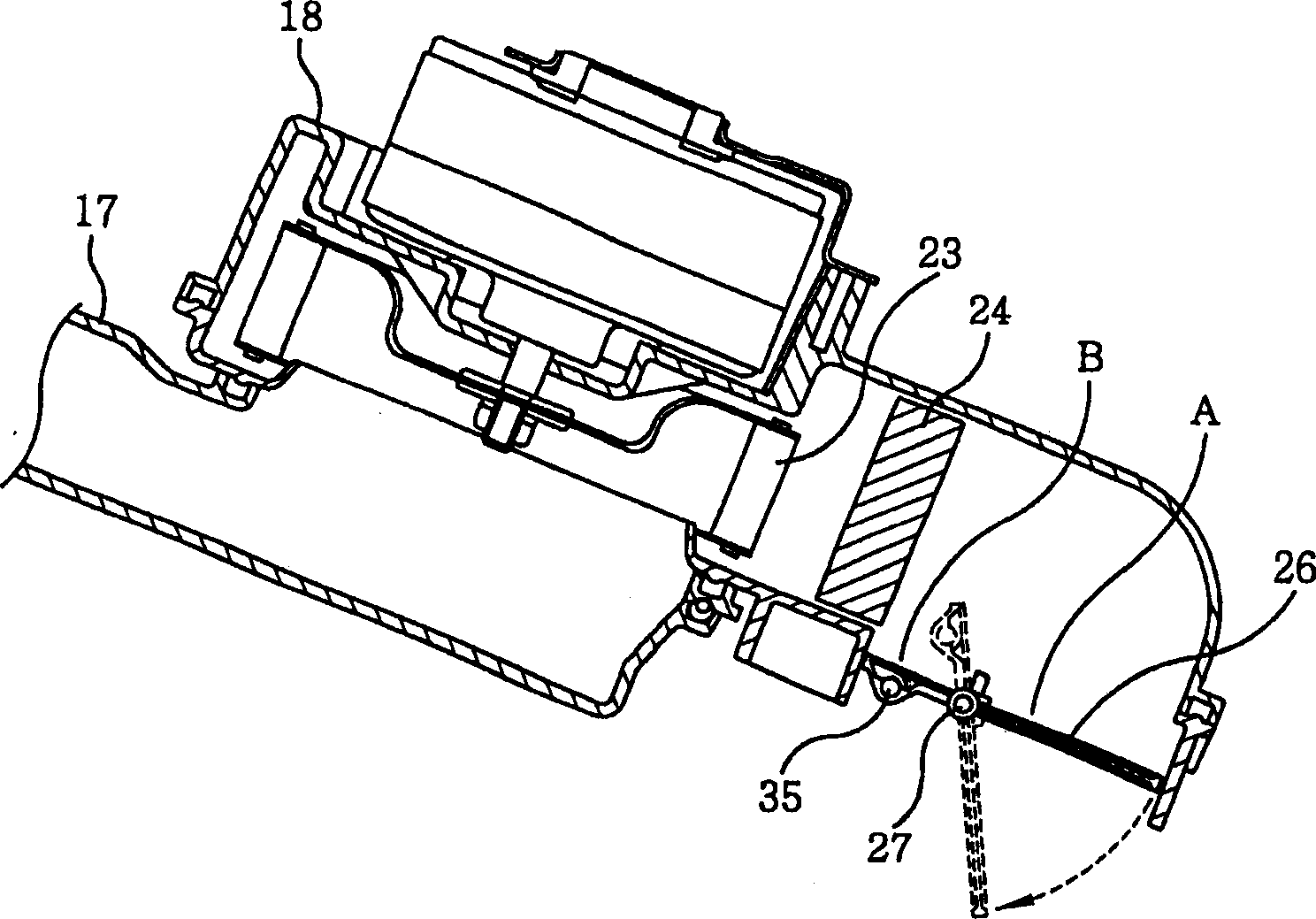

[0021] The drum type washing and drying machine of the present invention is as Figure 1~4 shown in . in, figure 1 It is an overall oblique view of the drum-type washer-dryer in this embodiment, figure 2 is a schematic sectional view of the drum-type washer-dryer, image 3 is a cross-sectional view of the blast heating passage and the adjacent main structures in the tumble-type washer-dryer, Figure 4 It is a bottom view of the forced air heating tunnel in this tumble washer dryer.

[0022] Such as figure 1 and figure 2 As shown in , in the main body 1 of the drum type washer-dryer, a water tub 3 in a suspended state is provided through the damping structure 2 and other components, and the water tub 3 is provided with a rotating drum 4 in the shape of a bottome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com