Light high-stiffness XY working platform and bonding head

A workbench and high-rigidity technology, applied in metal processing, electrical components, electrical solid devices, etc., to achieve the effects of stable machine operation, error elimination, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention utilizes the linear motor mounted on the base to drive the slider on the guide rail and the integrated movement of the bonding head to complete the processing of the semiconductor device.

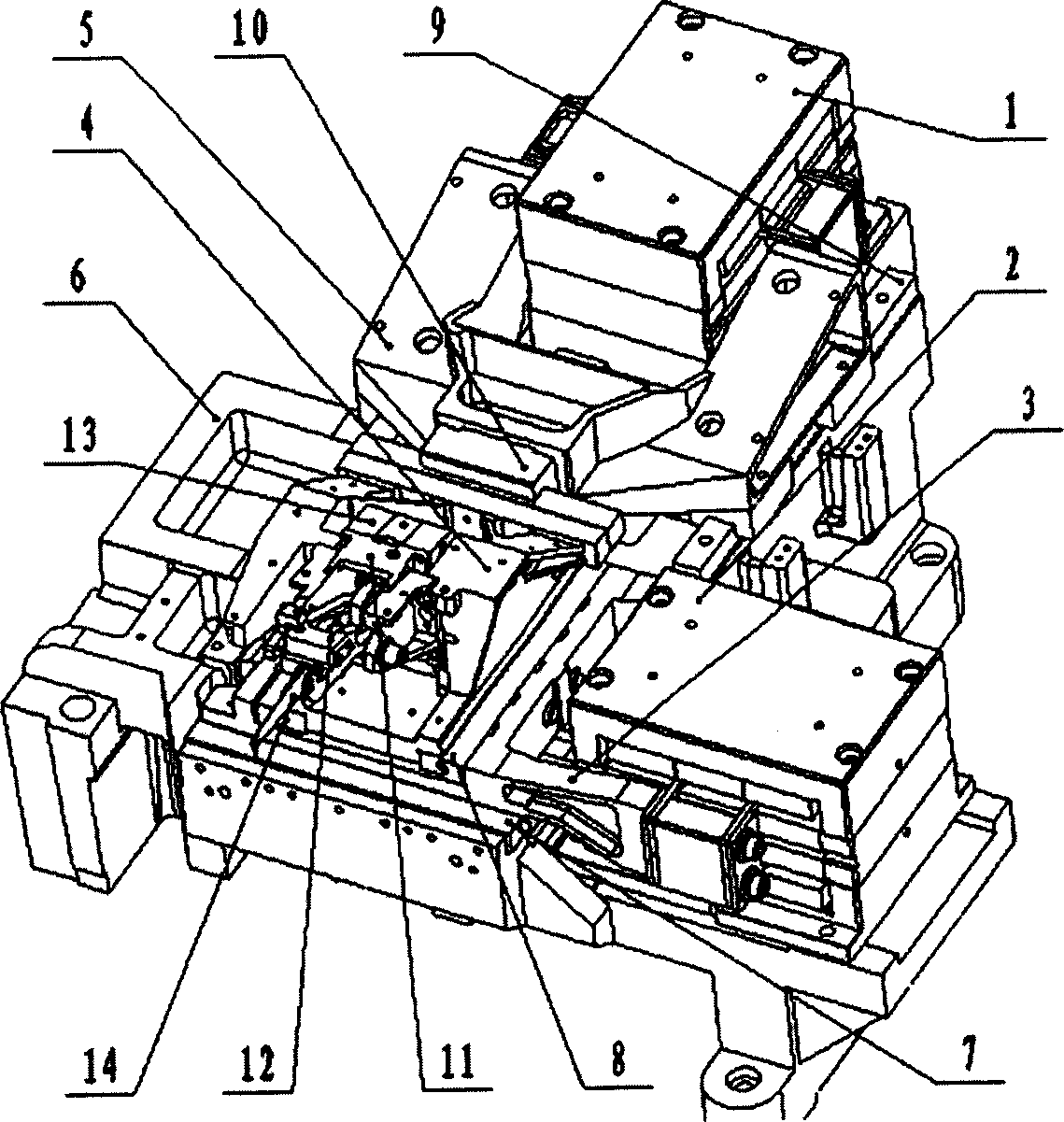

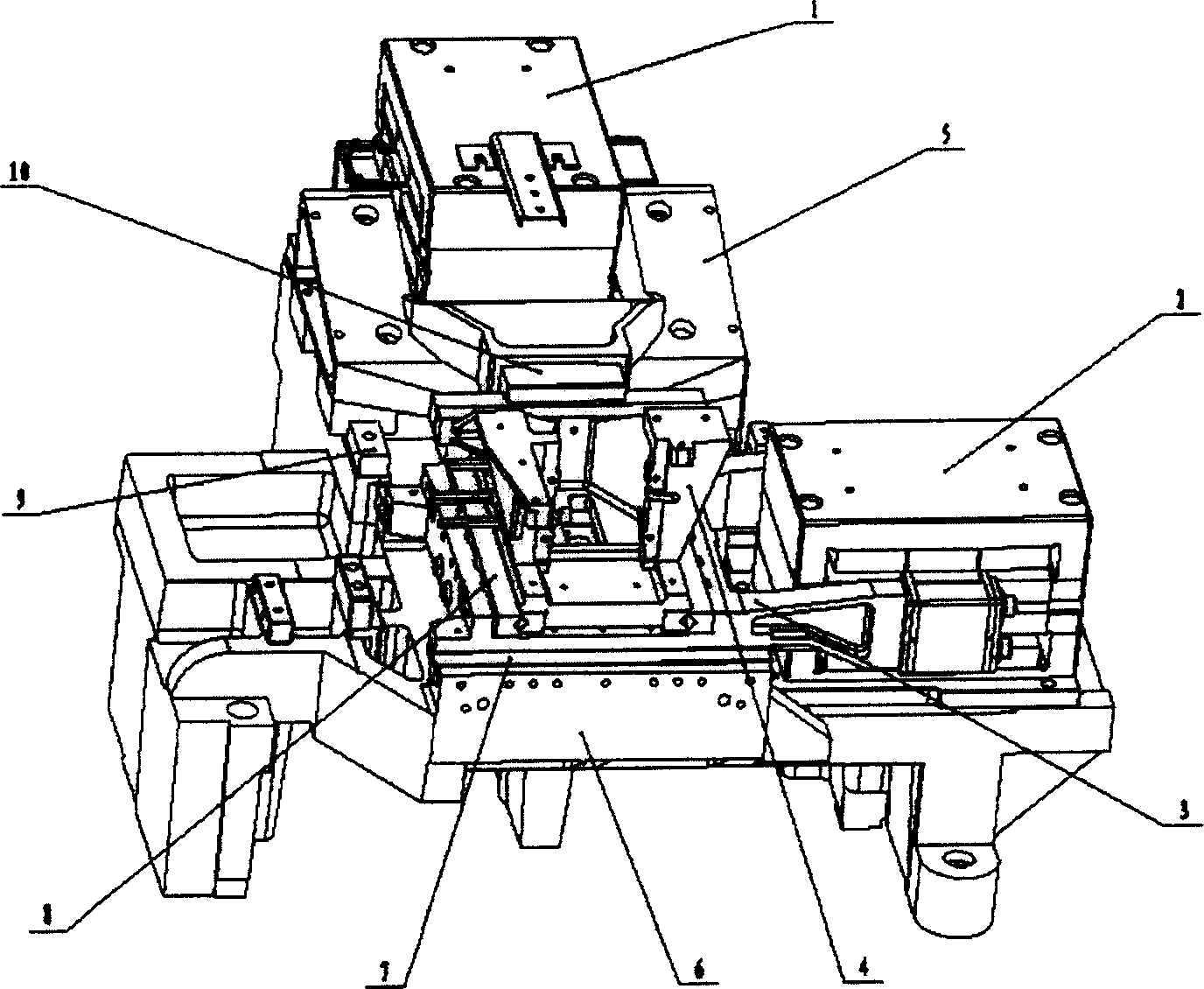

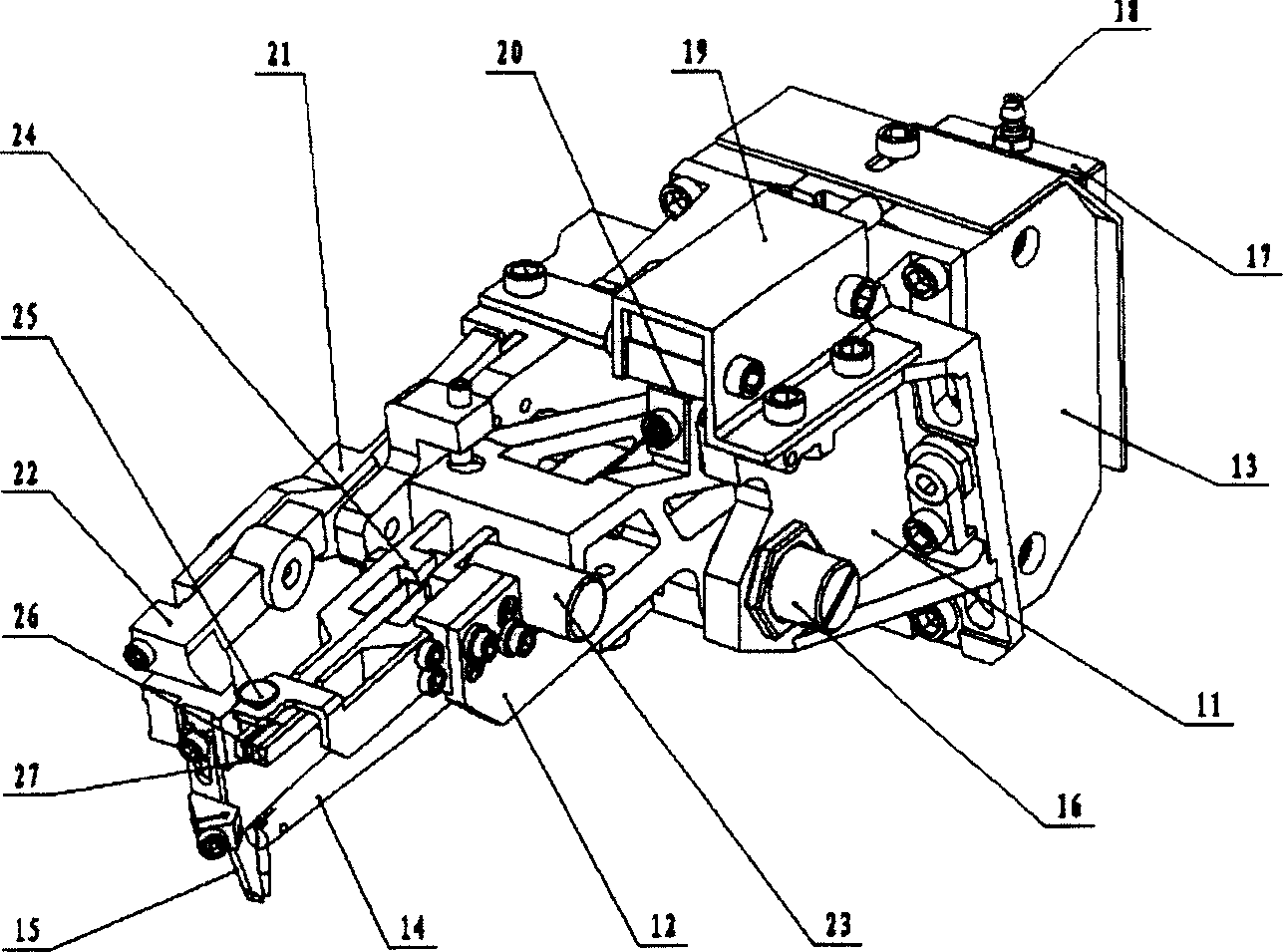

[0015] refer to figure 1 , figure 2 , image 3 In the present invention, the worktable is installed on the machine base 6 with fasteners, and the horizontal driving linear motor 2 and the longitudinal driving linear motor 1 are installed on the worktable. The transverse guide rail 7 on the worktable moves, the longitudinal front slide block 4 and the longitudinal front guide rail 8 are fixed on the transverse slide block 3, the longitudinal front slide block 4 is connected with the longitudinal rear slide block 5 through the decoupling mechanism 10, and the longitudinal rear slide block 5 It is installed on the longitudinal rear guide rail 9 fixed on the base 6 and connected with the longitudinal driving linear motor 1. The longitudinal driving linear motor 1 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com