Elastic stressing stress birefringence double-frequency laser

A stress birefringence, dual-frequency laser technology, applied in the field of helium-neon lasers, can solve the problems of difficulty in improving the resolution of the frequency difference of the laser, and cannot guarantee firm fixation, etc., and achieves the effect of improving the resolution of the afterburner and improving the control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

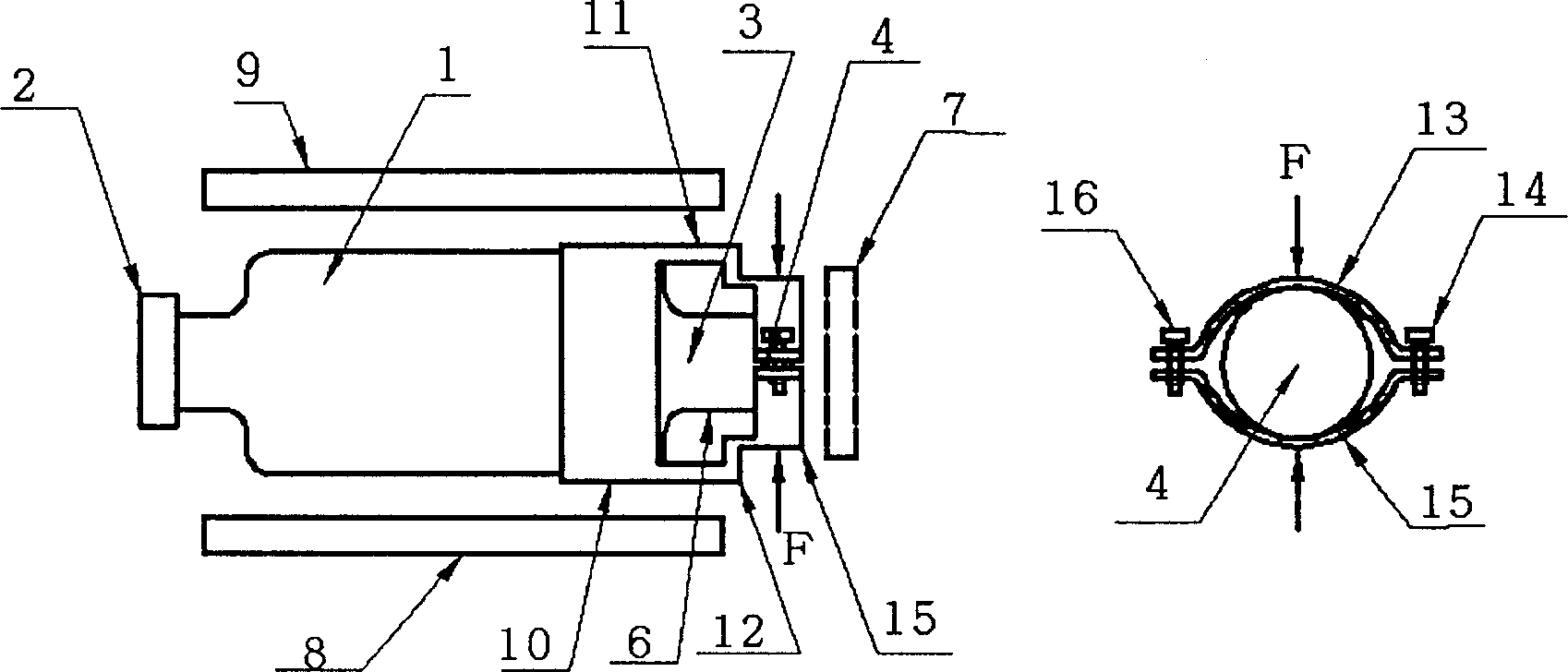

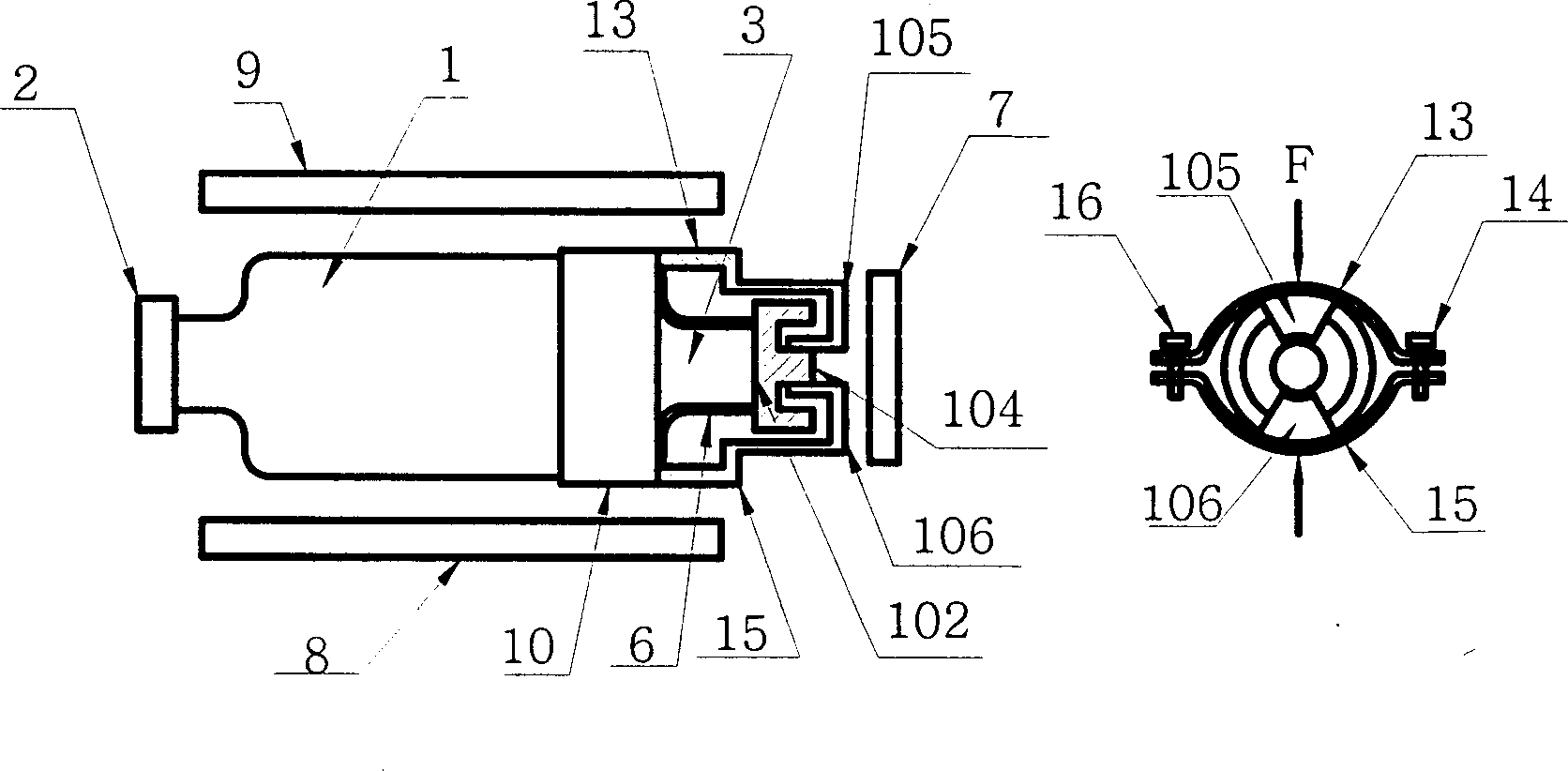

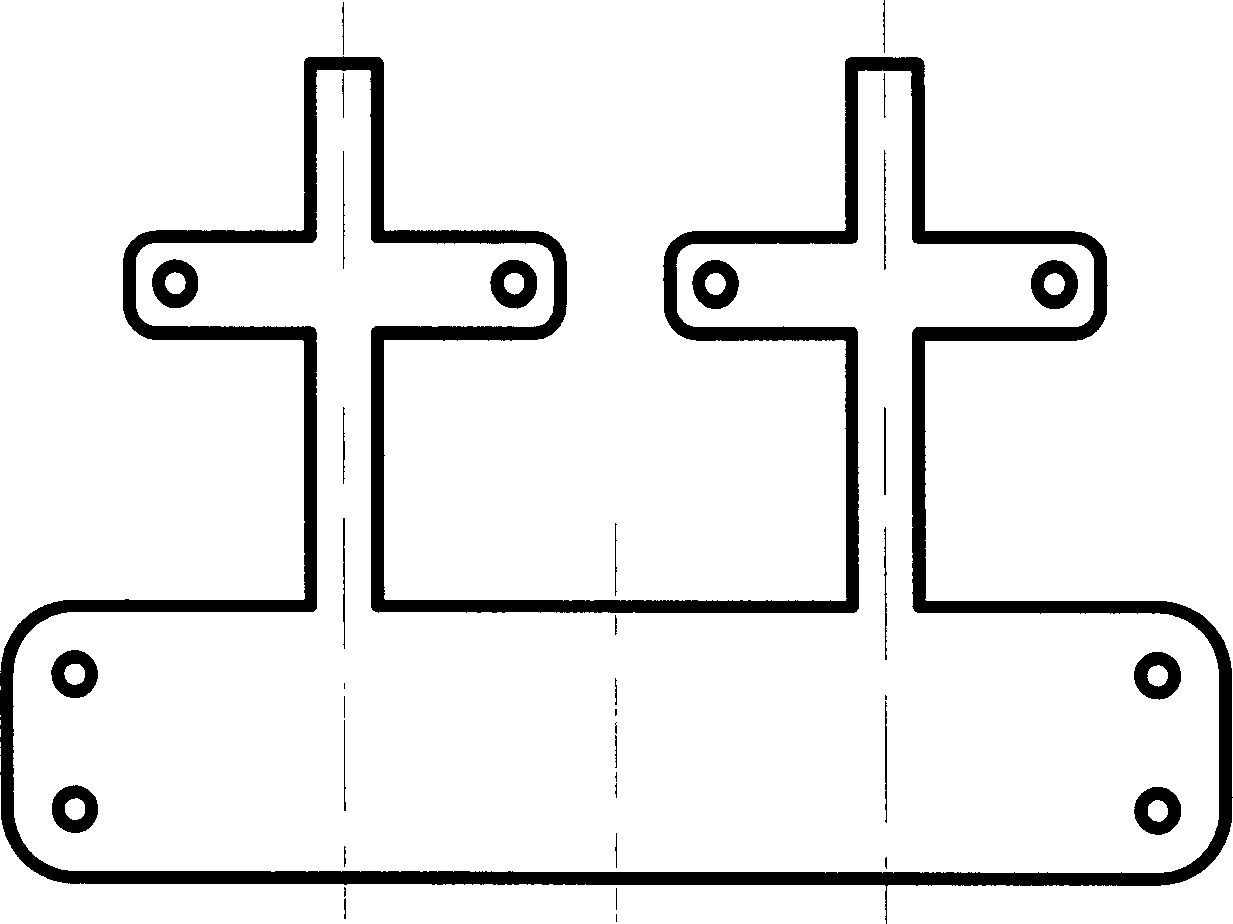

[0020] figure 1 It is an embodiment of applying force to the stress element on the He-Ne laser, and the force is applied to the center of the element from two directions along a vertical line of the entire element. figure 2 It is an embodiment of lateral force on the boss on the stress element on the He-Ne laser. The boss on the element is actually obtained by processing a groove on an optical element. image 3 is the plan view of the force-bearing element.

[0021] figure 1 The middle element 1 is a helium-neon laser discharge tube. Element 2 is a mirror for the laser. Element 3 is the tube neck. 4 is a laser reflector, and 2 is a laser resonator. For example, the laser is a semi-external cavity structure, 4 is an anti-reflection window, 7 is another laser cavity mirror, and 2 forms a laser resonator. The dotted line indicates that the laser is not used for the whole inner cavity, and this component is used for the half outer cavity. 8 and 9 are a pair of bar-shaped p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com