Tool holder and metal cutting insert with chip breaking surfaces

A technology for metal cutting and cutting blades, which is applied in the field of metal cutting blades and tool holders for clamping metal cutting blades, and can solve the problems of blade manufacturing cost increase and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The best way to practice the invention

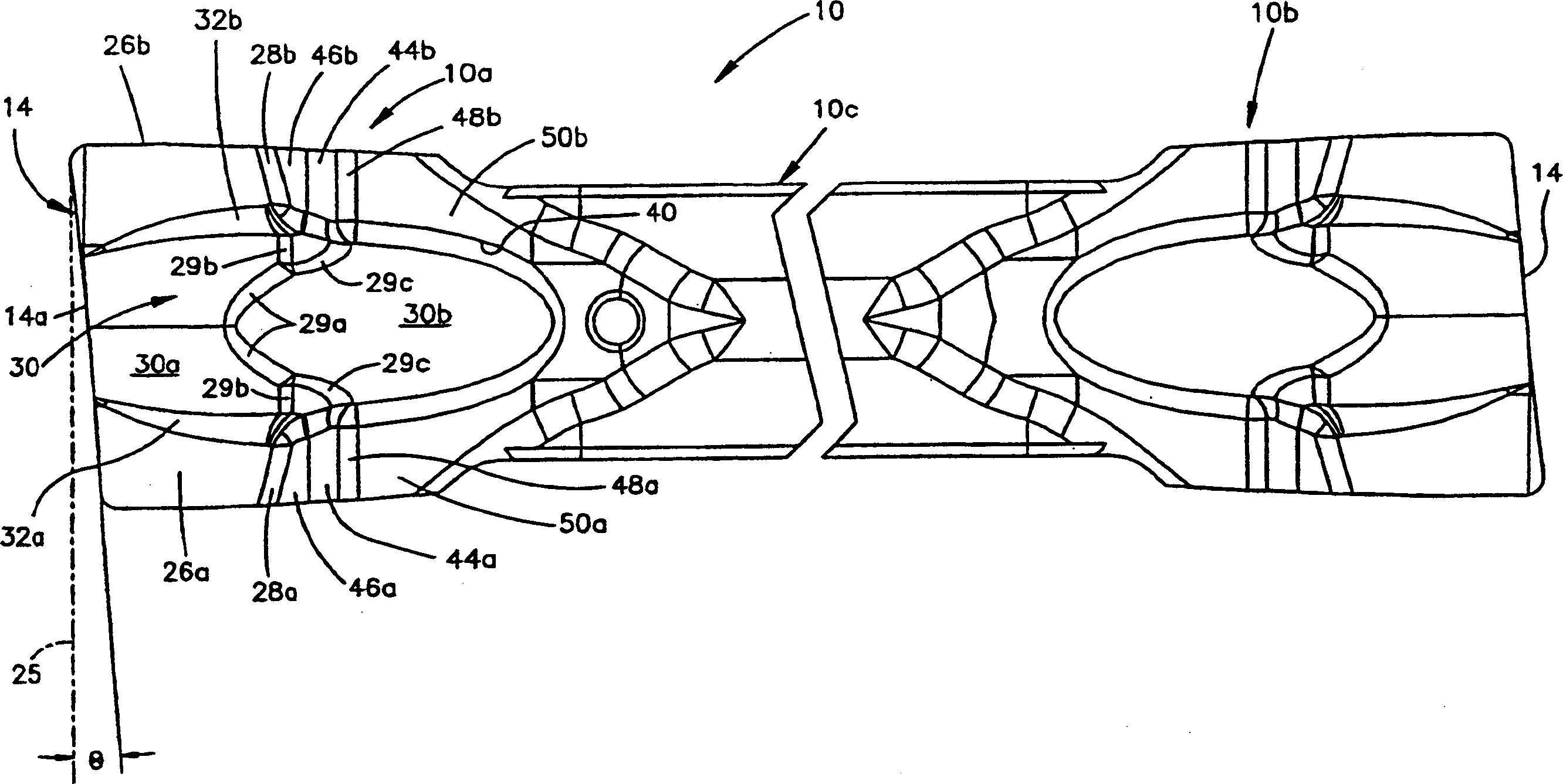

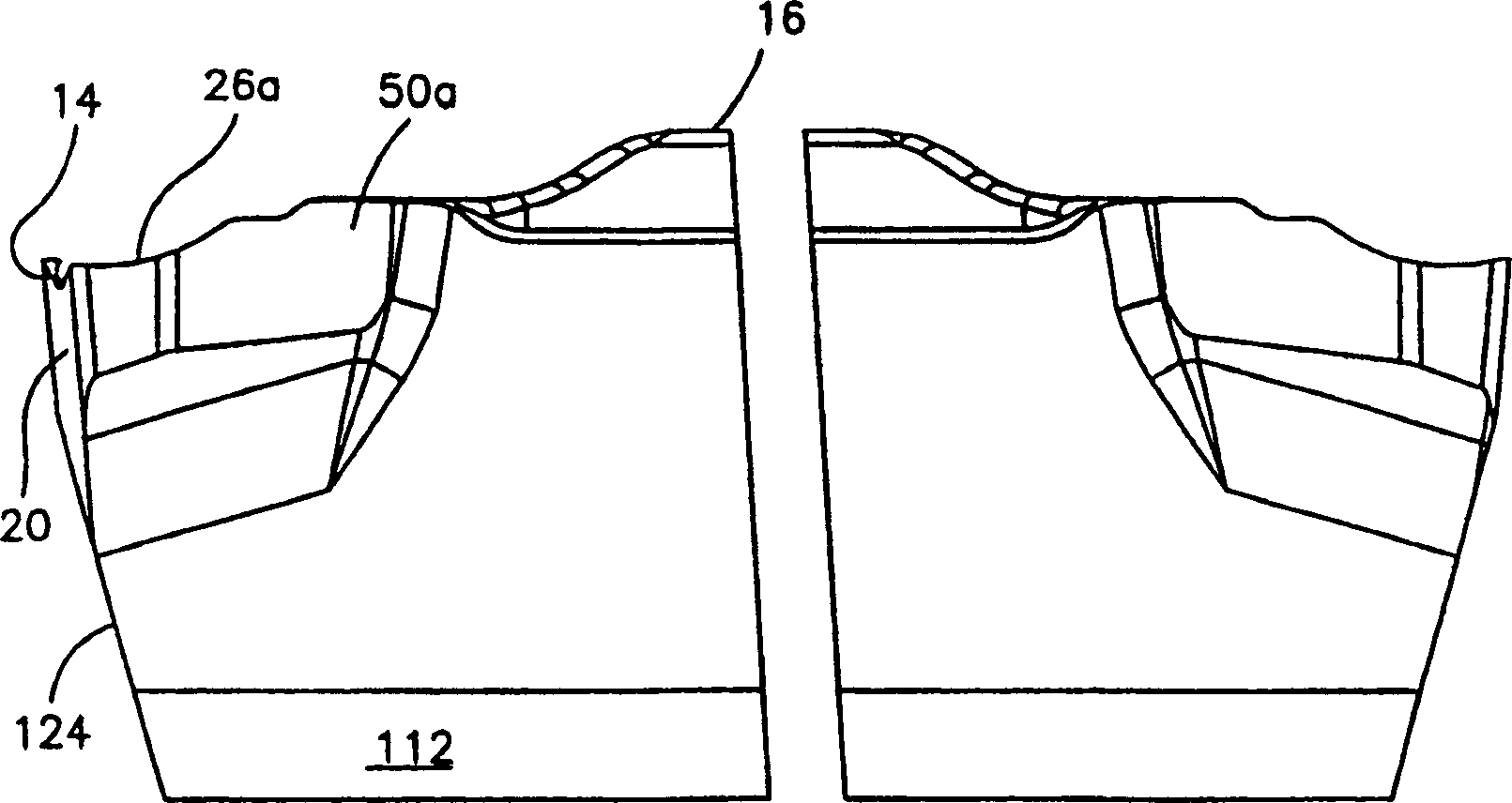

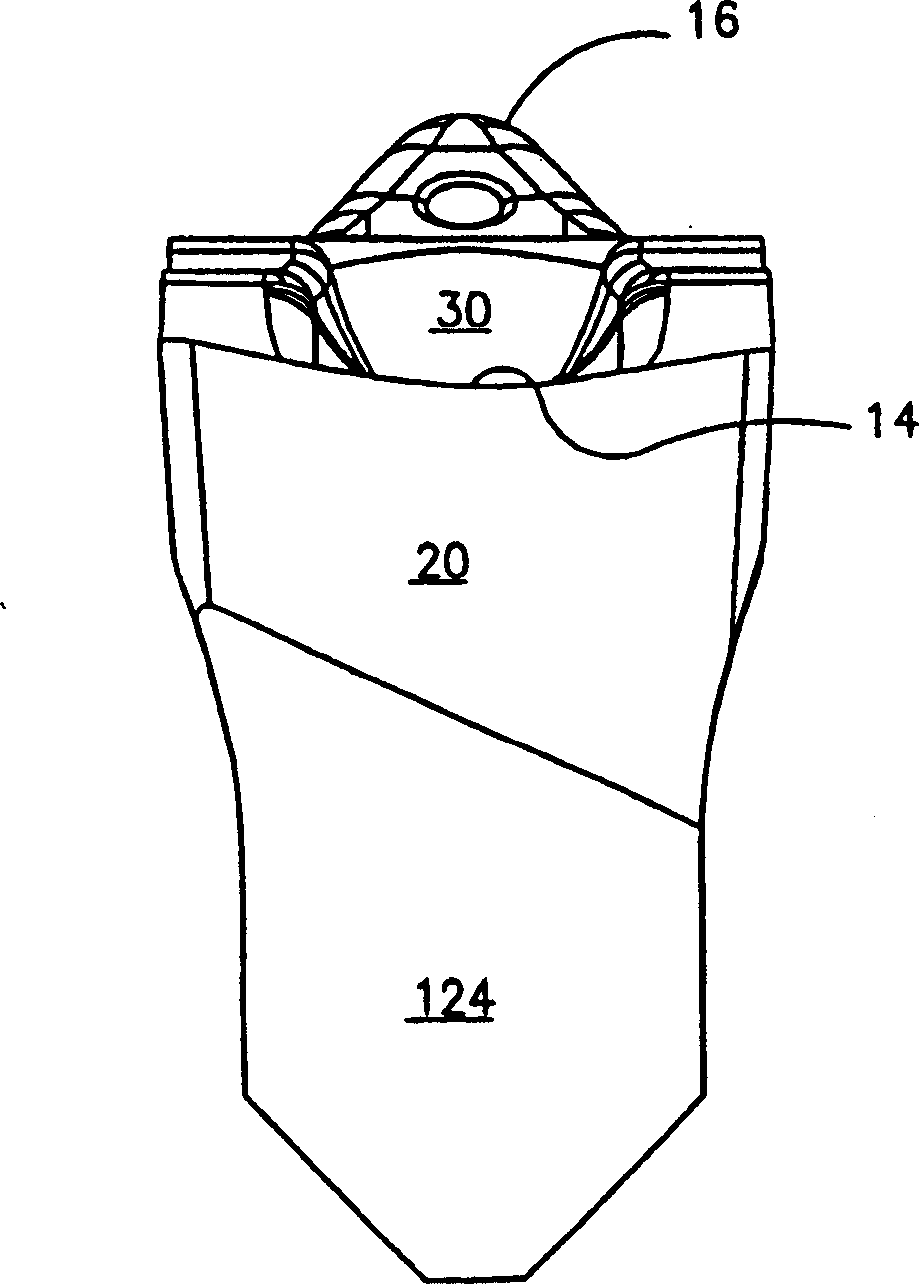

[0026] Figures 1 to 4 The general structure of a metal cutting insert 10 constructed in accordance with a preferred embodiment of the present invention is shown. In use, the blade 10 is clamped in the tool holder 100 (see Image 6 ). Generally speaking, the toolholder forms part of a sliding mechanism that positions the cutting edge 14 of the cutting insert 10 in contact with a rotating workpiece (not shown) for performing a cutting operation on the workpiece.

[0027] In the disclosed embodiment, the blade 10 includes a pair of cutting portions 10a, 10b on either side of a shank 10c. In use, the shank 10c of the blade 10 is clamped to the tool holder 100 (as Image 6 ), the toolholder 100 positions and supports one of the cutting parts, namely 10a, in a machining position. After this cutting portion 10a is worn, the insert 10 is rotated by 180° in the tool holder 100 in order to position the other cutting portion 10b in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com