Process for producing semiconductor devices, and semiconductor device

A manufacturing method and semiconductor technology, which are applied to the manufacture of semiconductor devices and the field of semiconductor devices, can solve problems such as poor moldability and poor flame retardancy of cured products, and achieve the effects of excellent moisture resistance reliability, improved production efficiency, and excellent balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

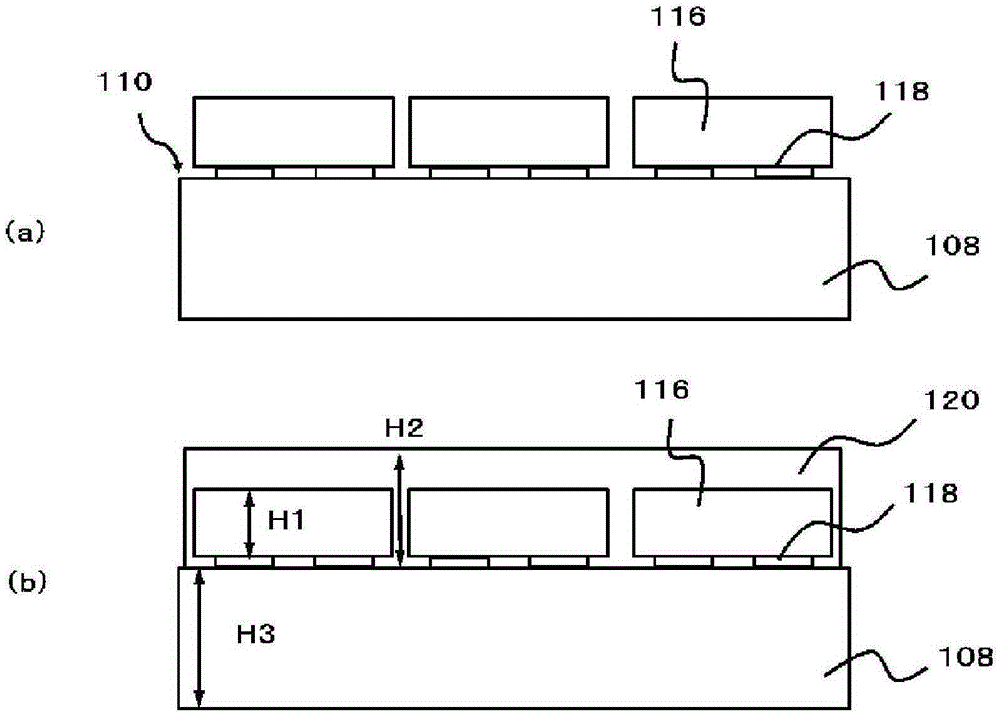

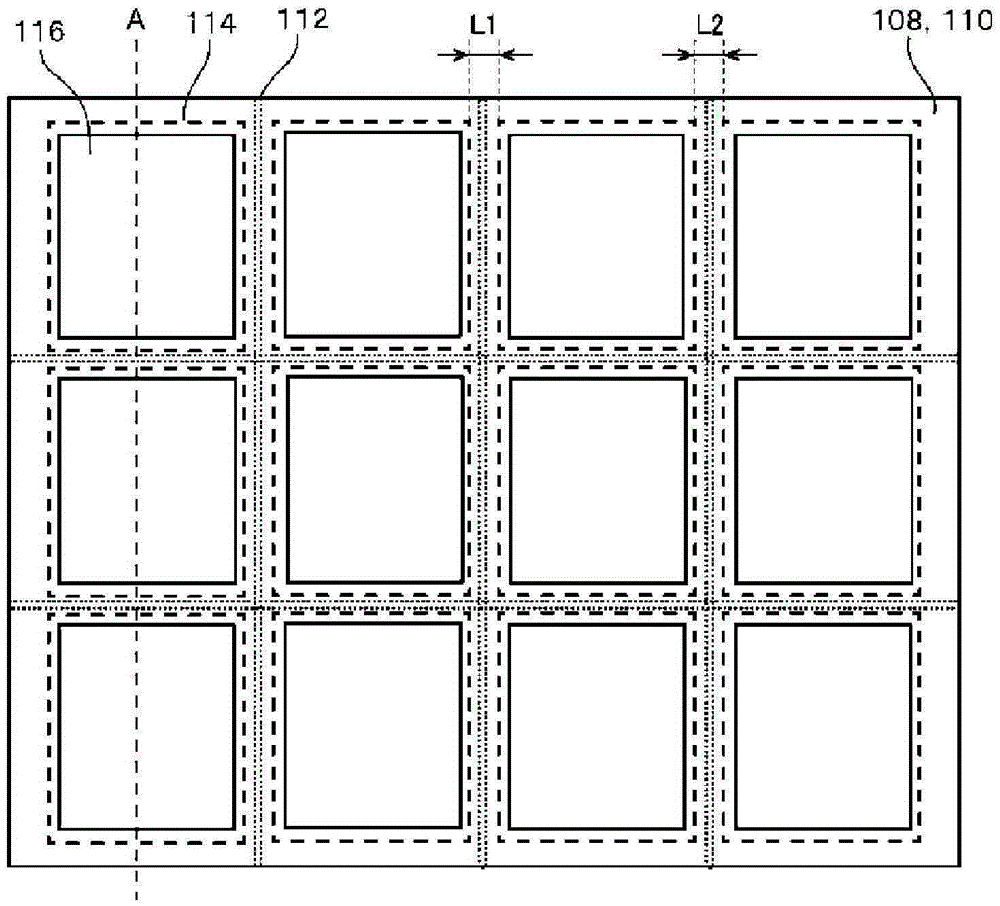

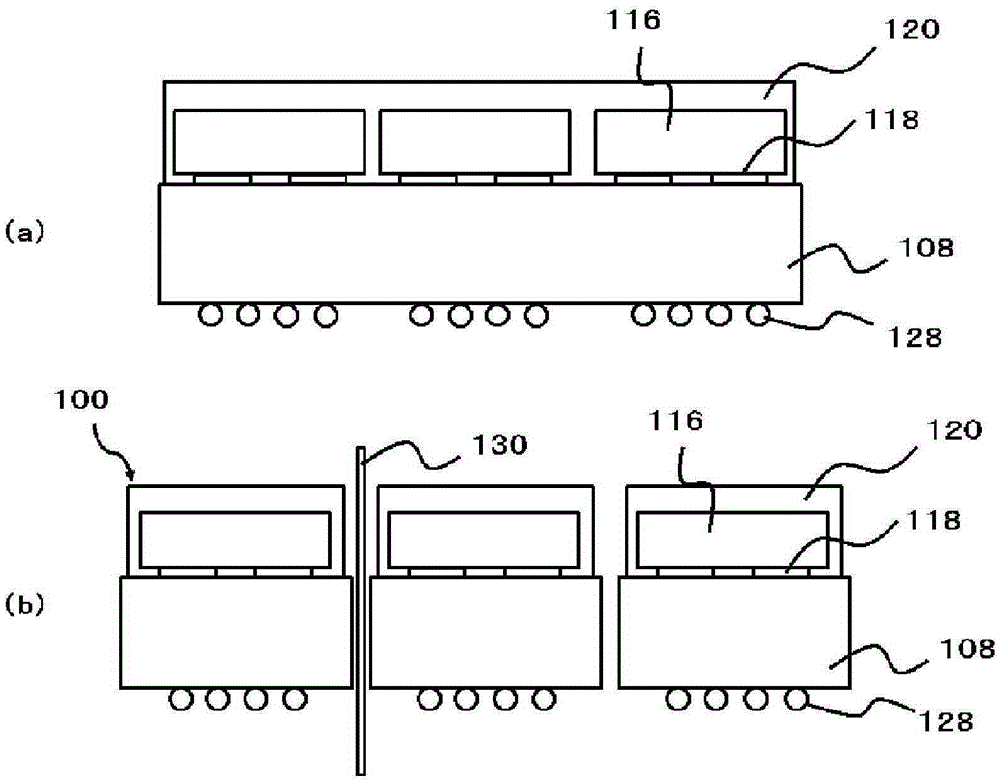

[0067] The manufacturing method of the semiconductor device 100 of this embodiment is called a so-called "MAP method" and includes the following steps. First, an element mounting substrate 108 including a plurality of packaging regions 114 partitioned by dicing regions 112 is prepared (hereinafter referred to as a preparation step). Then, the semiconductor chip 116 is mounted on each package area 114 of the element mounting substrate 108 (hereinafter referred to as a mounting step). Then, the semiconductor chip 116 is simultaneously molded with the epoxy resin composition for sealing (hereinafter, referred to as a molding process). Dicing is performed along the dicing region 112 to separate the individual molded semiconductor chips 116 (hereinafter referred to as a singulation process).

[0068] The epoxy resin composition for sealing of this embodiment contains (A) epoxy resin, (B) curing agent, (C) silicone resin, (D) inorganic filler, (E) curing accelerator, (C) organic T...

no. 2 approach >

[0239] Although the method of manufacturing a semiconductor device called the so-called "MAP method" in the first embodiment is shown, the above-mentioned epoxy resin composition for sealing can also be applied to electronic component assemblies (sometimes referred to as packaging or PKG) as exemplified below. ).

[0240] That is, Patent Document 7 shows an example of a single-sided sealed electronic component assembly for vehicle use, in which electronic components are mounted on one side of a circuit board and electrically connected to terminals of a lead frame with electric wires. The other side of the circuit board is bonded to the heat sink via the adhesive layer. A mold package in which terminals of these circuit boards, electronic components, heat sinks, and lead frames are sealed with a mold resin has been disclosed, and attempts have been made to prevent peeling by designing the package structure.

[0241] However, in the above-mentioned electronic components, if the...

Embodiment 1

[0342] Weigh epoxy resin 1 (8.00 parts by mass), phenolic curing agent 1 (5.00 parts by mass), inorganic filler 1 (75.00 parts by mass), inorganic filler 2 (10.00 parts by mass), hardening accelerator 4 (0.20 parts by mass), silane coupling agent 1 (0.20 parts by mass), release agent 1 (0.20 parts by mass), silicone resin 1 (1.00 parts by mass), colorant 1 (0.40 parts by mass), and mix them with a mixer Then, kneading was performed using two rolls whose surface temperatures were 95° C. and 25° C., thereby obtaining a kneaded product. Then, the epoxy resin composition for sealing of Example 1 was obtained by pulverizing this kneaded material after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com