Heater for generating hot air and its electric wire insulator

A technology of insulators and heating wires, applied in the direction of air heaters, fluid heaters, heating elements, etc., can solve the problems of wiring obstacles, poor appearance, etc., and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Next, the best mode for carrying out the invention will be described with reference to the drawings.

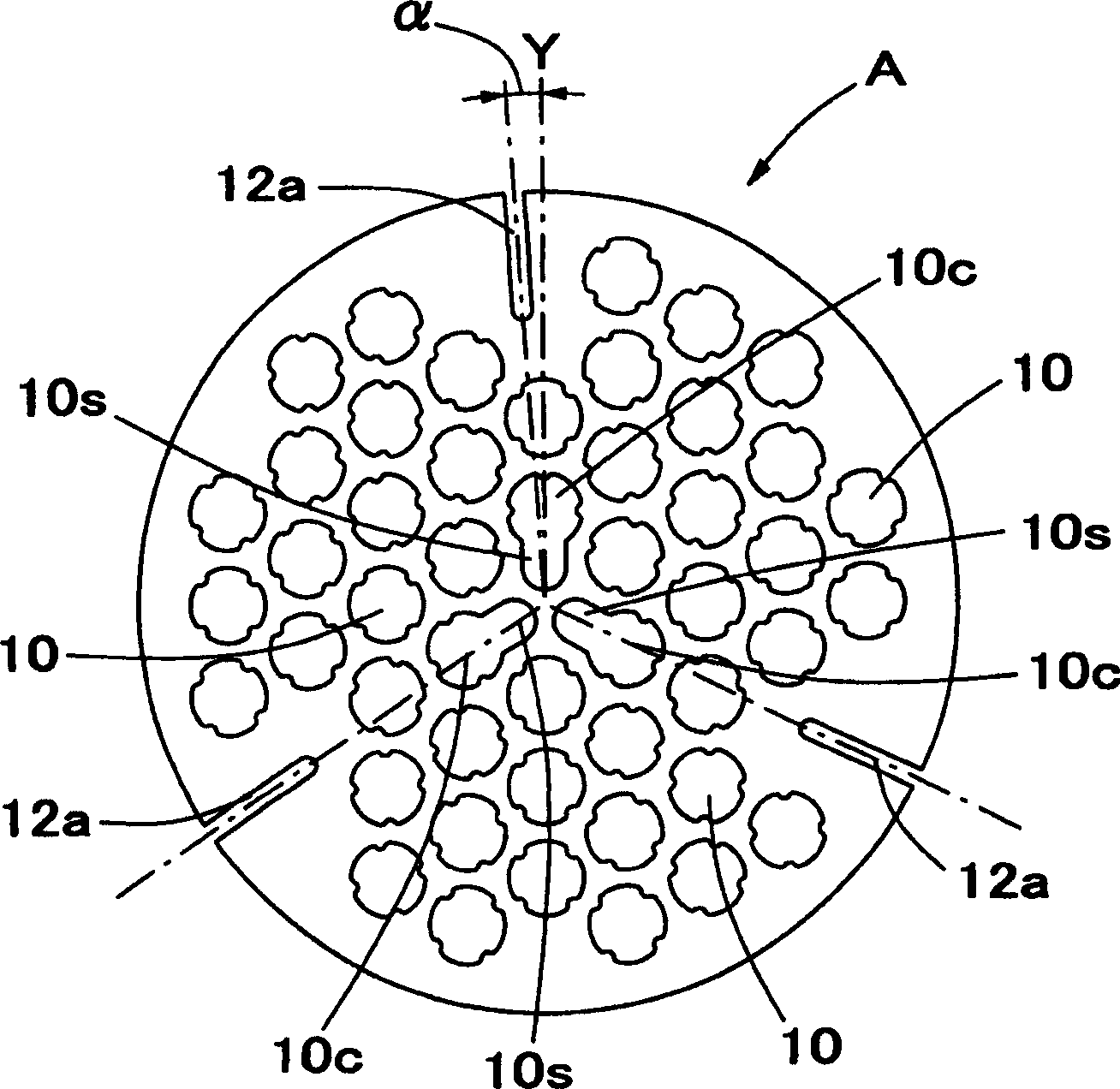

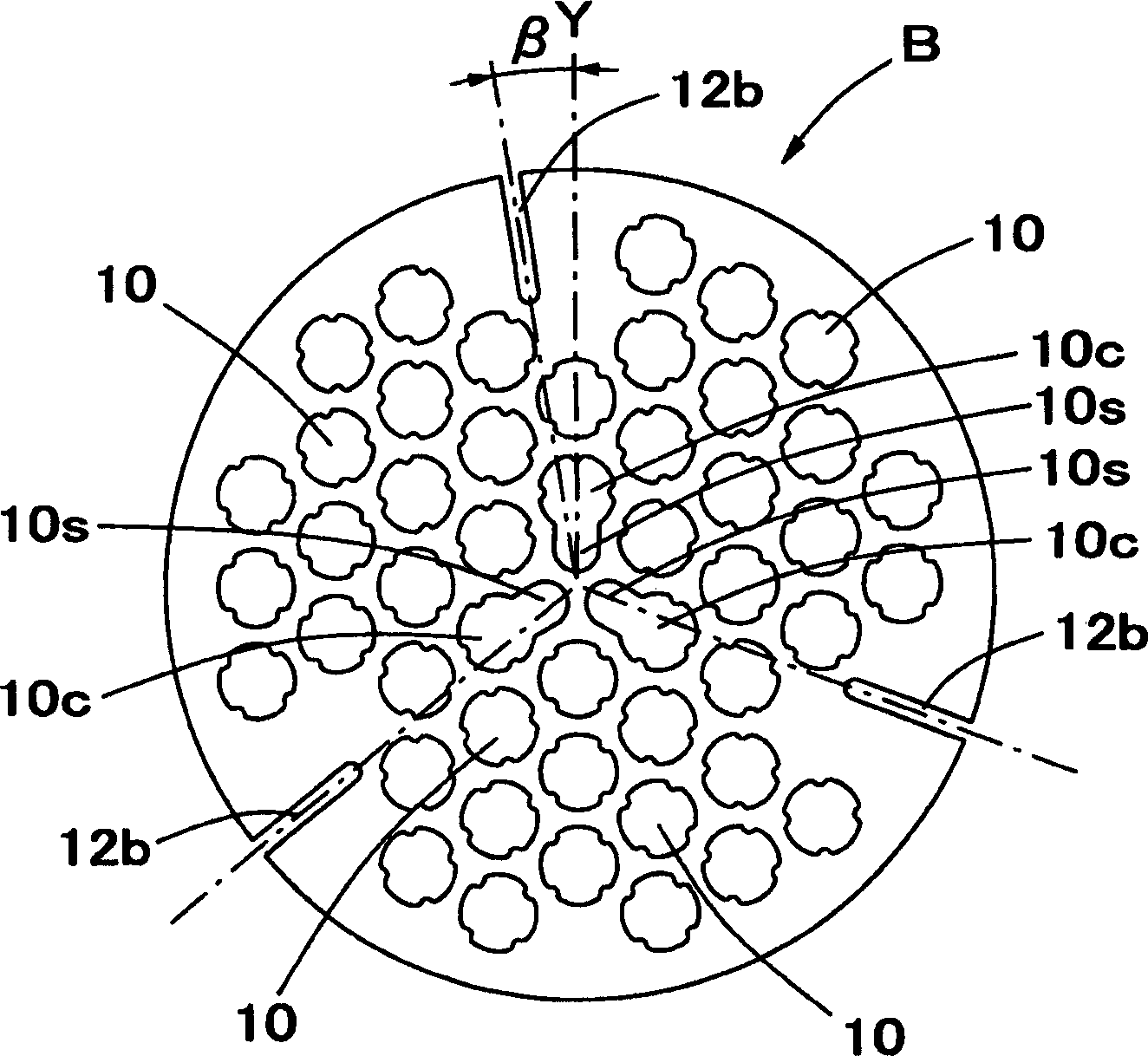

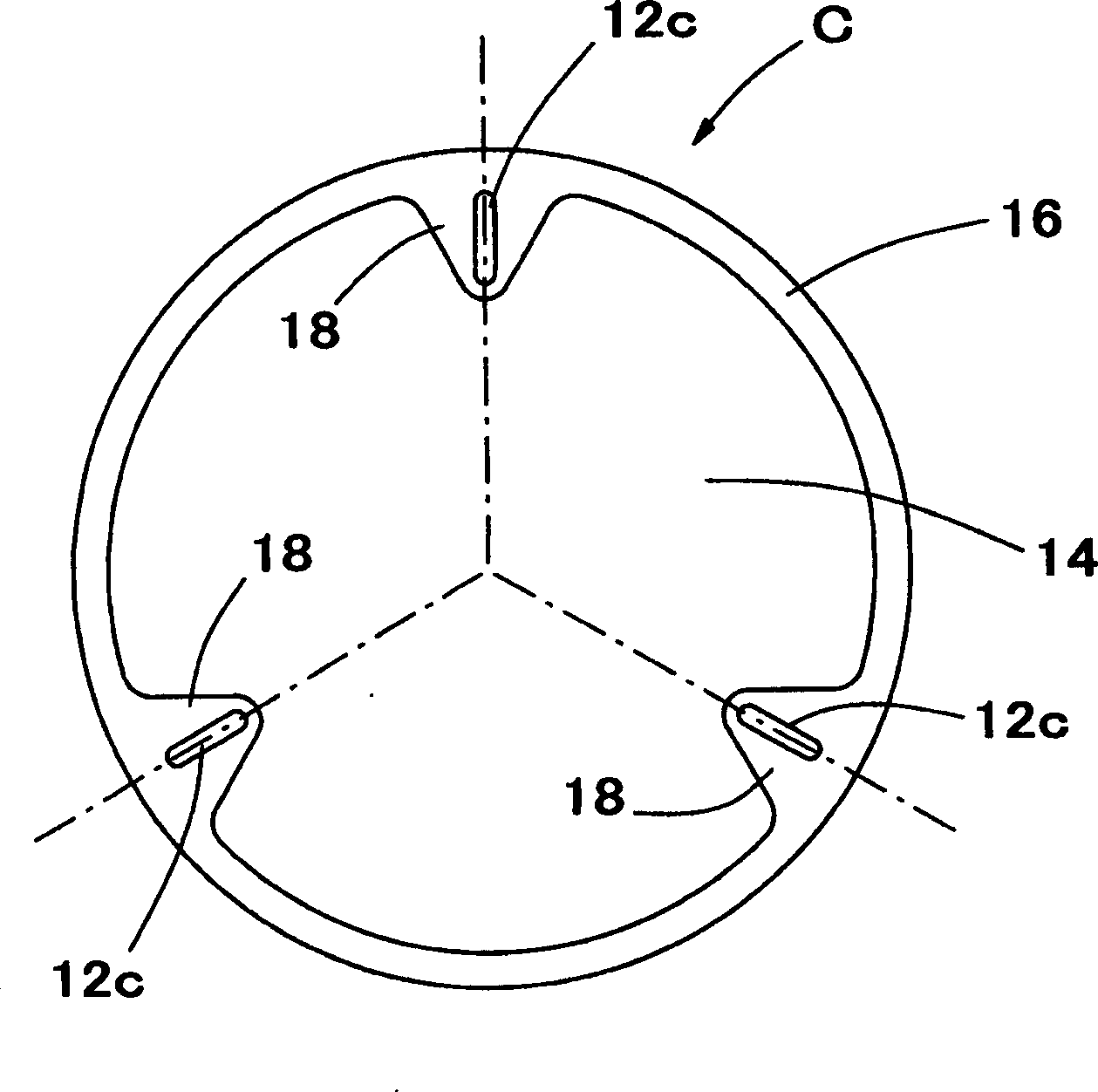

[0059] Figure 1 to Figure 3 It is a front view respectively showing three types of structural sheets for constituting a group of insulators for heating wires according to the present invention viewed from the direction of gas flow, figure 1 Indicates the insulator structure sheet A, figure 2 Indicates the insulator structure piece B, image 3 Indicates spacer insulator C. in addition, Figure 4 It is a perspective front view of the state where these three structural sheets are superimposed along the direction of gas flow, Figure 5 It is an explanatory side view illustrating a state in which three sets of such insulators for heating wires are accommodated and arranged inside the heater for generating hot air.

[0060] first, figure 1 The shown insulator structural sheet A is composed of a disk-shaped plate-shaped body having a constant thickness and a circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com