High-temperature-resistant ultrahigh-density oil-based drilling fluid and preparation method thereof

An oil-based drilling fluid and ultra-high density technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems affecting the safety of deeper oil and gas, high-efficiency development, subsidence stability damage, system rheological deterioration, etc. problems, to avoid the settlement of heavy materials, improve the stability of settlement, and stabilize the flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

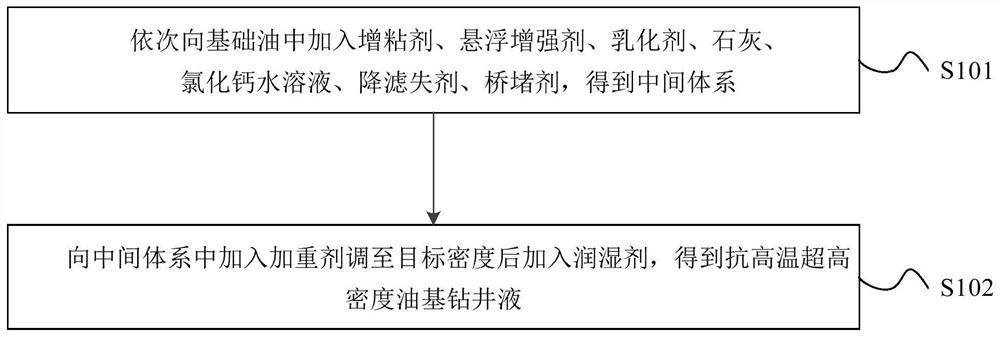

[0062] figure 1 It is the flow chart of the preparation method of high temperature resistant ultra-high density oil-based drilling fluid of the present invention, as figure 1 Shown, preparation method of the present invention comprises the following steps:

[0063] S101: adding viscosifier, suspension enhancer, emulsifier, lime, calcium chloride aqueous solution, fluid loss reducer, and bridging agent to the base oil in sequence to obtain an intermediate system;

[0064] Wherein, when the emulsifier includes polyamide fatty acid and anionic emulsifier, the polyamide fatty acid is added first, and then the anionic emulsifier is added.

[0065] In addition, the amount of calcium chloride aqueous solution added can be determined according to the emulsification state of the mixture of base oil, viscosifier, suspension enhancer, emulsifier and lime, and try to ensure that the mixture after adding calcium chloride aqueous solution is in a homogeneous state.

[0066] S102: Add a we...

Embodiment 1

[0076] The base fluid of the high-temperature-resistant ultra-high-density oil-based drilling fluid of this embodiment includes the following components according to mass percentage:

[0077] Base oil (0# diesel): 27.9%

[0078] Viscosifier (high temperature and high pressure wet processing organic bentonite): 0.07%

[0079]Suspension enhancer (hydroxyapatite): 0.07%

[0080] Anti-high temperature main emulsifier (polyamide fatty acid): 6.66%

[0081] Anti-high temperature co-emulsifier (anionic emulsifier): 0.60%

[0082] Lime: 50.4%

[0083] Fluid loss control agent (polyvinyltoluene / acrylate copolymer): 6.85%

[0084] Bridging agent (calcium carbonate mixture of different particle sizes): 6.85%

[0085] Wetting agent (sulfonate surfactant): 0.60%

[0086] Weighting agents include:

[0087] A calcium chloride aqueous solution with a mass concentration of 25% and a weighting agent, wherein the weighting agent includes barite, micromanganese ore powder and micro ilmenit...

Embodiment 2

[0097] The composition of the high-temperature-resistant ultra-high-density base liquid of the present embodiment is the same as that of Example 1, and the weight control agent (calcium chloride aqueous solution and mass ratio is barite, micromanganese ore powder and micro-ilmenite powder of 3:1:1 Weighting agent) addition is different from embodiment 1.

[0098] The preparation method of the high-temperature-resistant ultra-high-density oil-based drilling fluid of the present embodiment comprises the following steps:

[0099] 1) Preparation of intermediate system

[0100] After adding tackifier to base oil, stir for 5 minutes, add suspension enhancer and stir for 5 minutes, add polyamide fatty acid and stir for 5 minutes, add anionic emulsifier and stir for 5 minutes, add lime and stir for 5 minutes, add calcium chloride aqueous solution Stir for 15 minutes, add the fluid loss control agent and stir for 5 minutes, then add the bridging agent and stir for 5 minutes to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com