Solid oxide fuel cell system

A fuel cell system and solid oxide technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of reduction of condensed water, cost, difficulty in self-supply of water, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

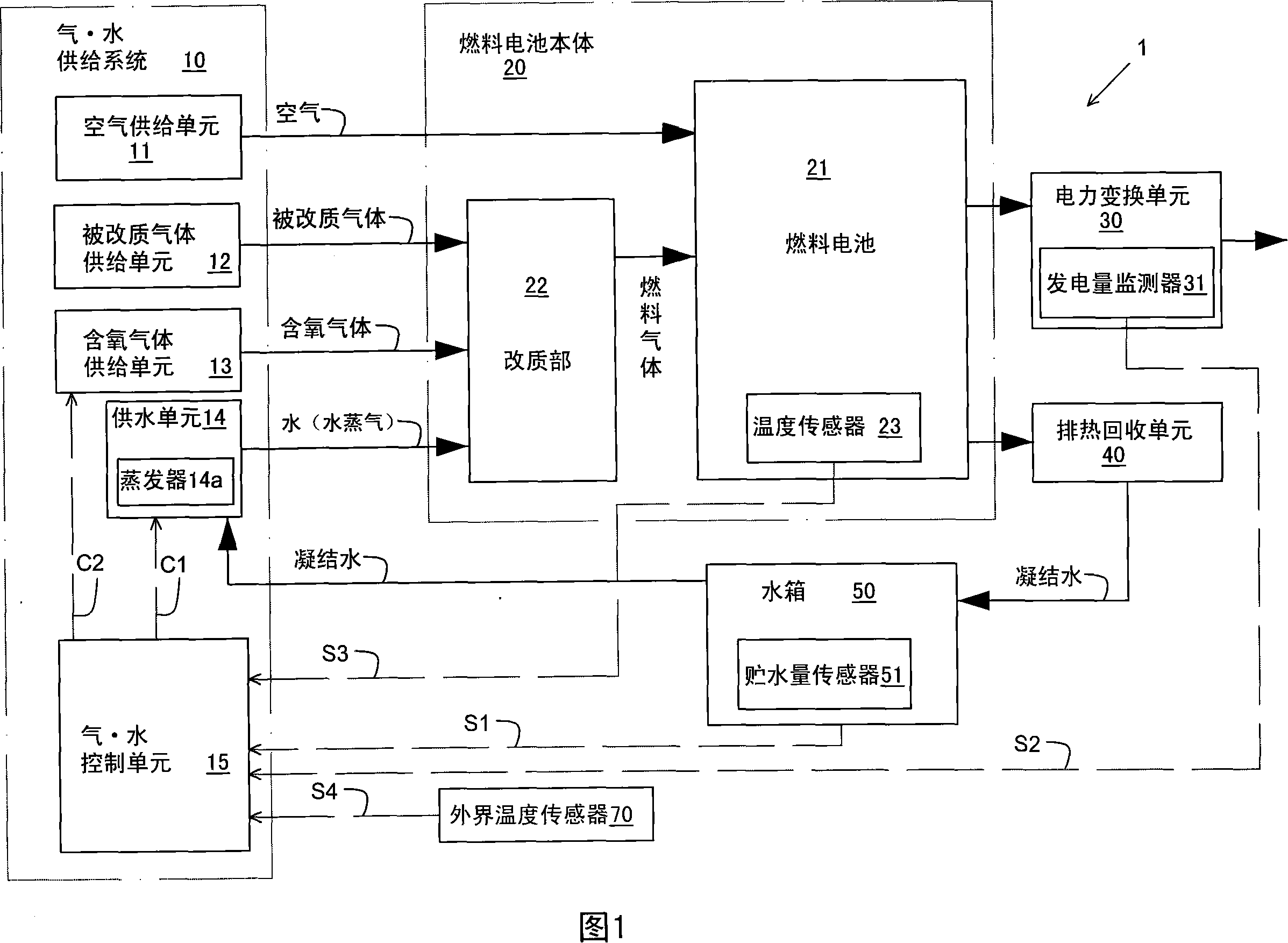

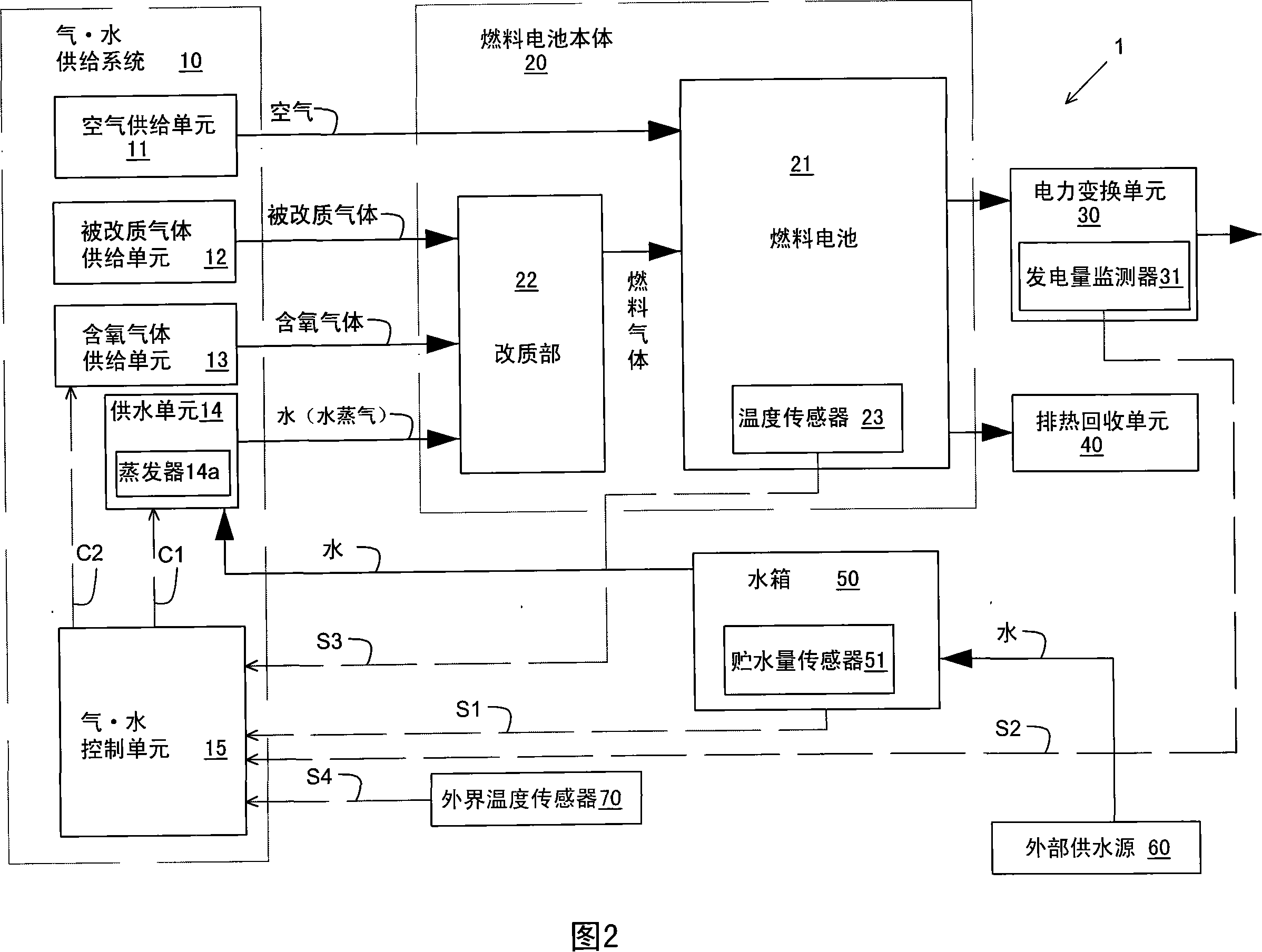

[0043] Figure 1 is a simplified block diagram of a solid oxide fuel cell system 1 of the present invention. Inside the fuel cell main body 20 is provided a fuel cell 21 which is an aggregate of small cells sandwiching an electrolyte between a pair of electrodes. In this way, the heat generated by the power generation reaction of the fuel cell 21 and the combustion heat of the excess gas can be used for the reforming reaction in the reforming part 22 .

[0044] The system is also provided with an air-water supply system 10 for supplying various gases and water to the fuel cell main body 20, supplying various gases or water with appropriate supply pipes connected to the fuel cell main body 20, and supplying various gases or water from the air supply unit 11 to the fuel cell main body 20. The fuel cell 21 supplies oxygen-containing air. Then, the hydrogen-rich fuel gas reformed in the reforming part 22 is supplied to the fuel cell 21, thereby generating a power generation reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com