Improved axial force balancing structure of shielded pump

A technology of balancing structure and axial force, applied to parts, pumps, pump elements, etc. of pumping devices used for elastic fluids, can solve problems that cannot be effectively avoided, so as to increase service life, improve working conditions, reduce The effect of bearing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

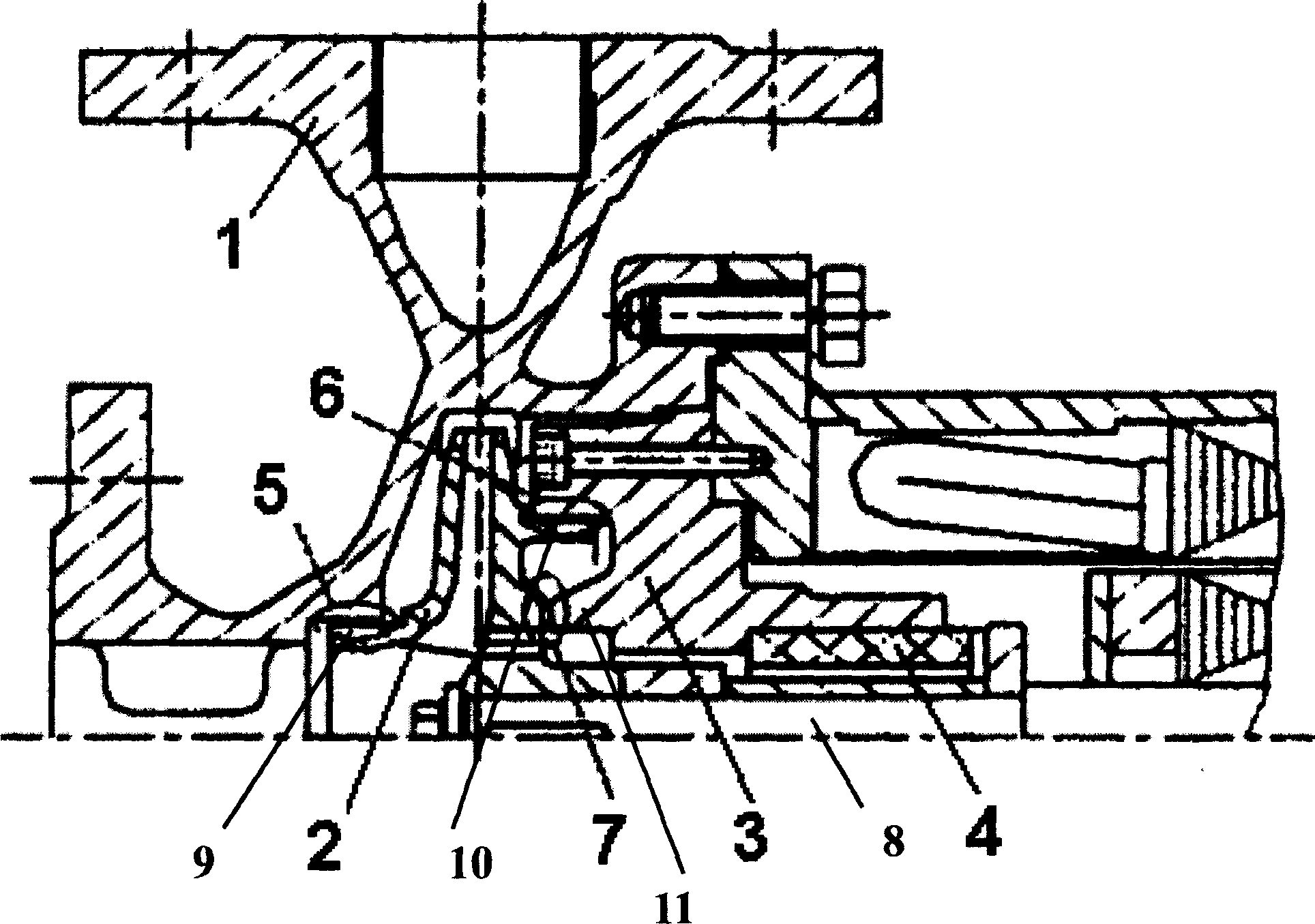

[0011] Such as figure 1 As shown, the improved shielded pump axial force balance structure of the present invention is composed of a pump body 1, a pump shaft 8, an impeller 2 and a bearing seat 3, the bearing seat 3 is arranged in the pump body 1, and the The bearing housing 3 is provided with a bearing 4, the pump shaft 8 is disposed in the bearing 4, the impeller 2 is sleeved on the pump shaft 8 and is located in front of the bearing housing 3 , wherein, the front cover of the impeller 2 is provided with a cylindrical boss 9, the axis of the cylindrical boss 9 coincides with the axis of the pump shaft 8, the The inner side of the pump body 1 on the front side of the impeller 2 is provided with a first cylindrical cavity, the axis line of the first cylindrical cavity coincides with the axis line of the cylindrical boss 9, and the The cylindrical boss 9 is arranged in the first cylindrical cavity, and a first gap is provided between the outer peripheral surface of the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com