Coating device of demoulding agent of mould

A coating device and release agent technology, applied in the direction of spraying device, electrostatic spraying device, etc., can solve the problems of large spray volume, stickiness around moisture, and high cost of water-based release agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

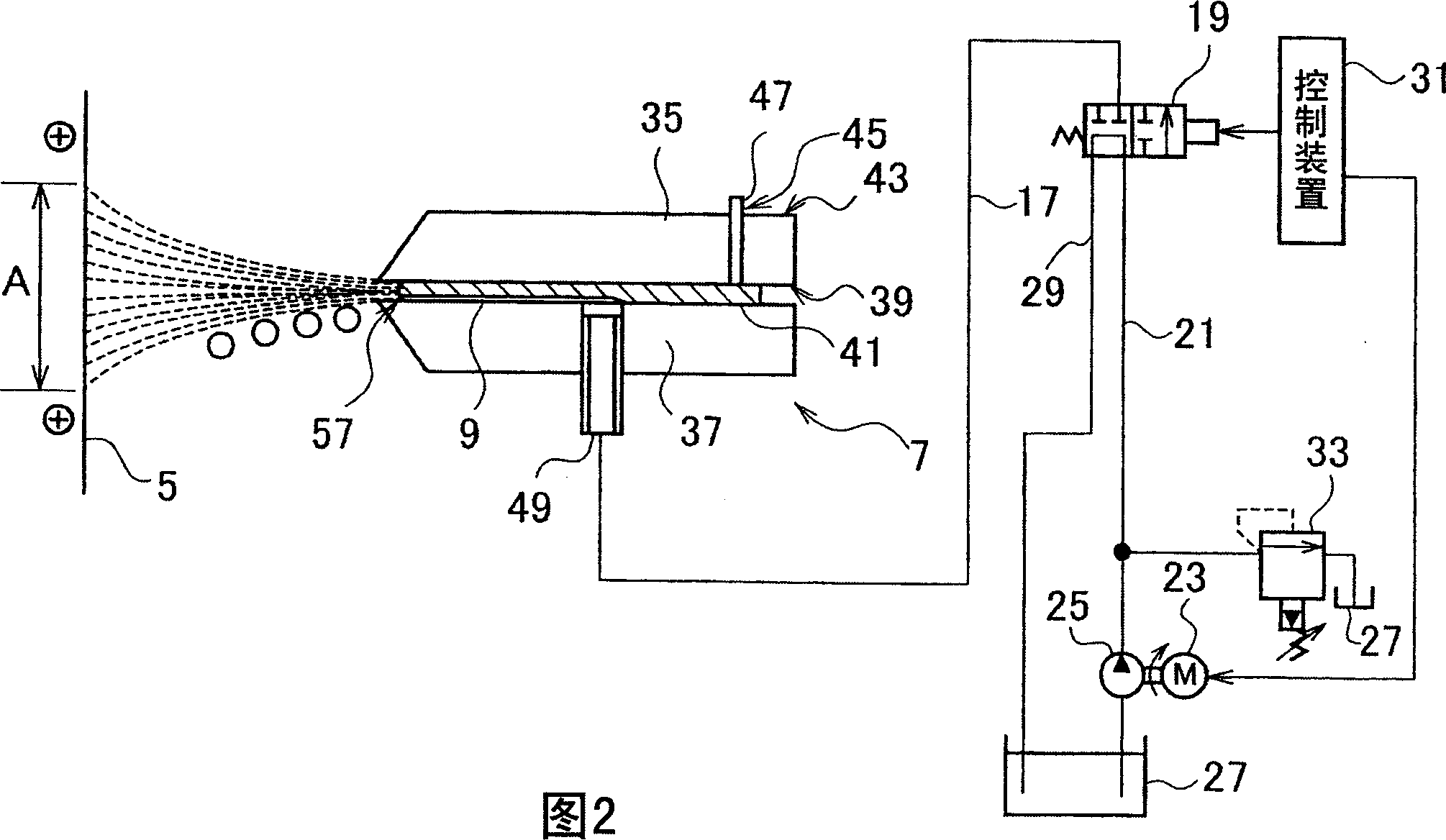

[0028] A mold release agent coating device 1 according to a first embodiment of the present invention will be described with reference to FIGS. 1 and 2 . A description will be given using, for example, the mold 3 for injection molding as the object to be coated. This injection mold 3 is configured by vertically arranging a pair of first mold 3A and second mold 3B, and a cavity is formed on each molding surface 5 of the first and second molds 3A, 3B. As shown in FIG. 1 , a pair of first and second dies 3A and 3B are arranged at a predetermined interval so that the molding surfaces 5 of the first and second dies 3A and 3B face each other.

[0029] In addition, the mold release agent coating device 1 according to the first embodiment of the present invention is an electrostatic type. Equipped with the ejection channel group 9 for ejecting the oil-based release agent to the molding surfaces 5 of the first and second molds 3A, 3B, and the nozzle 7 for applying high voltage to char...

no. 2 Embodiment approach

[0057] In the above-mentioned first embodiment, an example in which an oil-based mold release agent is applied to the molding surfaces 5 of the pair of first and second molds 3A, 3B constituting the mold 3 for injection molding on both sides of the nozzle 7 is described. It is applicable to multiple pairs of molds 3 with the nozzle 7 sandwiched in the middle and arranged oppositely on both sides of the nozzle 7 .

[0058] Figure 4 It is a plan view of the mold release agent coating device 1 according to the second embodiment of the present invention. For example, two pairs of molds 3 are arranged facing each other at a predetermined interval with the nozzles 7 interposed therebetween. At this time, the molding surfaces 5 sides of the molds 3 of the two pairs are arranged to face each other.

[0059] In addition, the inversion (turning) angle of the nozzle 7 is not limited to 180° as in the above-mentioned embodiment, and can be inverted at any angle. In addition, since the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com