Grinding machnie used for processing linear guide rail

A linear guide, grinding machine technology, applied in machine tools, grinders, metal processing equipment and other directions suitable for grinding workpiece planes, can solve the problems of affecting the accuracy of the guide rail, affecting the accuracy of the motion of the guide rail, and high surface roughness, so as to eliminate the high roughness. , Improve the bearing capacity and service life of the guide rail, and the effect of the good sealing performance of the guide rail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below, the present invention will be described in more detail in conjunction with the accompanying drawings and embodiments.

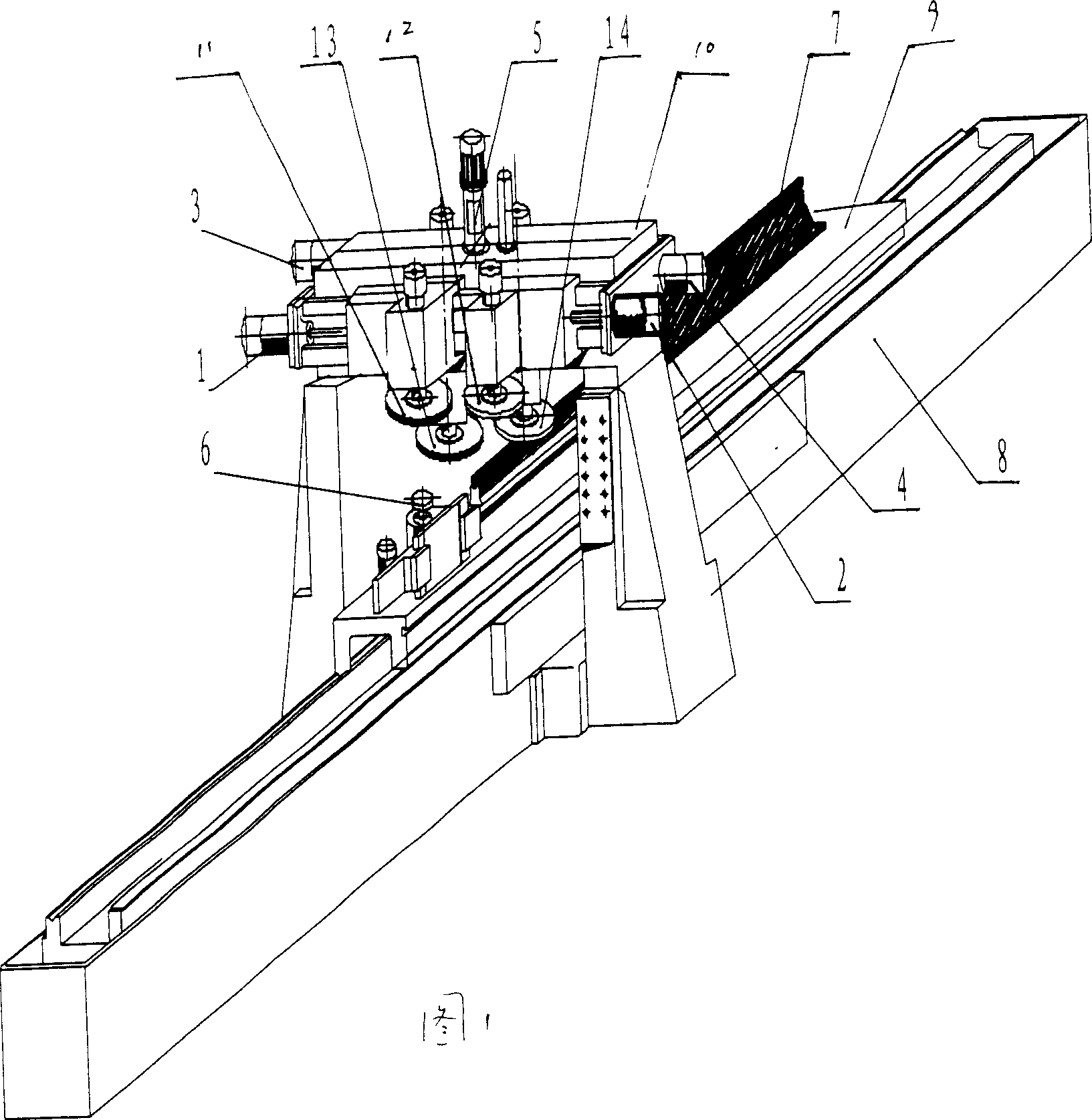

[0009] As shown in Figure 1, the grinding machine for processing linear guide rails consists of a bed 8, a workbench 9 placed on the bed, and a fixture 7 on the workbench. A gantry 10 is provided above the bed 8, and the gantry 10 It consists of columns and beams on both sides. Two pairs of servo motors 1, 2, 3, and 4 are arranged on both sides of the front and rear beams of the gantry 10. The servo motors 1, 2, 3, and 4 are directly connected to the ball screws respectively. The servo motors 1, 2, 3, 4 drive the feed carriage through the ball screw, and the electric spindle is fixed on the feed carriage, and the lower end of each electric spindle is respectively provided with movable grinding wheels 11, 12, 13, 14, which are controlled by The electric spindle fixed on the feed carriage drives the grinding wheel to rotate at a high speed for gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com