Piping structure for transporting a fuel, resin tube for transporting fuel in the piping structure and producing method thereof

A technology of resin pipes and pipes, applied in the direction of pipes/pipe joints/pipe fittings, the arrangement combined with the fuel supply of internal combustion engines, pipe supports, etc., which can solve the problems of large vibration of resin pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

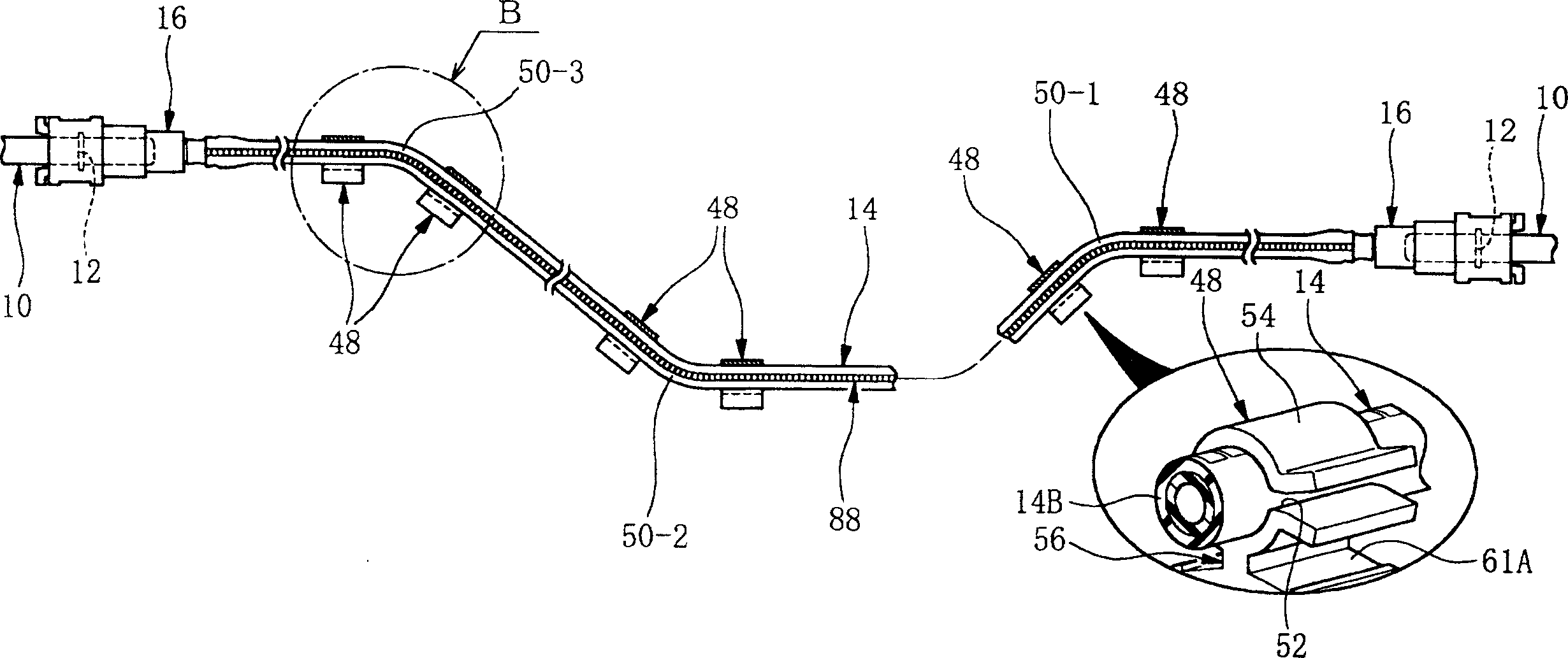

[0139] Referring to Figures 2 and 3, reference numeral 10 is a mating duct 10 integrally formed with a component part such as an engine or a fuel tank firmly fixed to the vehicle body. The fitting pipe 10 is formed with an engaging projection (pipe-side engaging portion) 12 projecting annularly on its outer peripheral surface and around it.

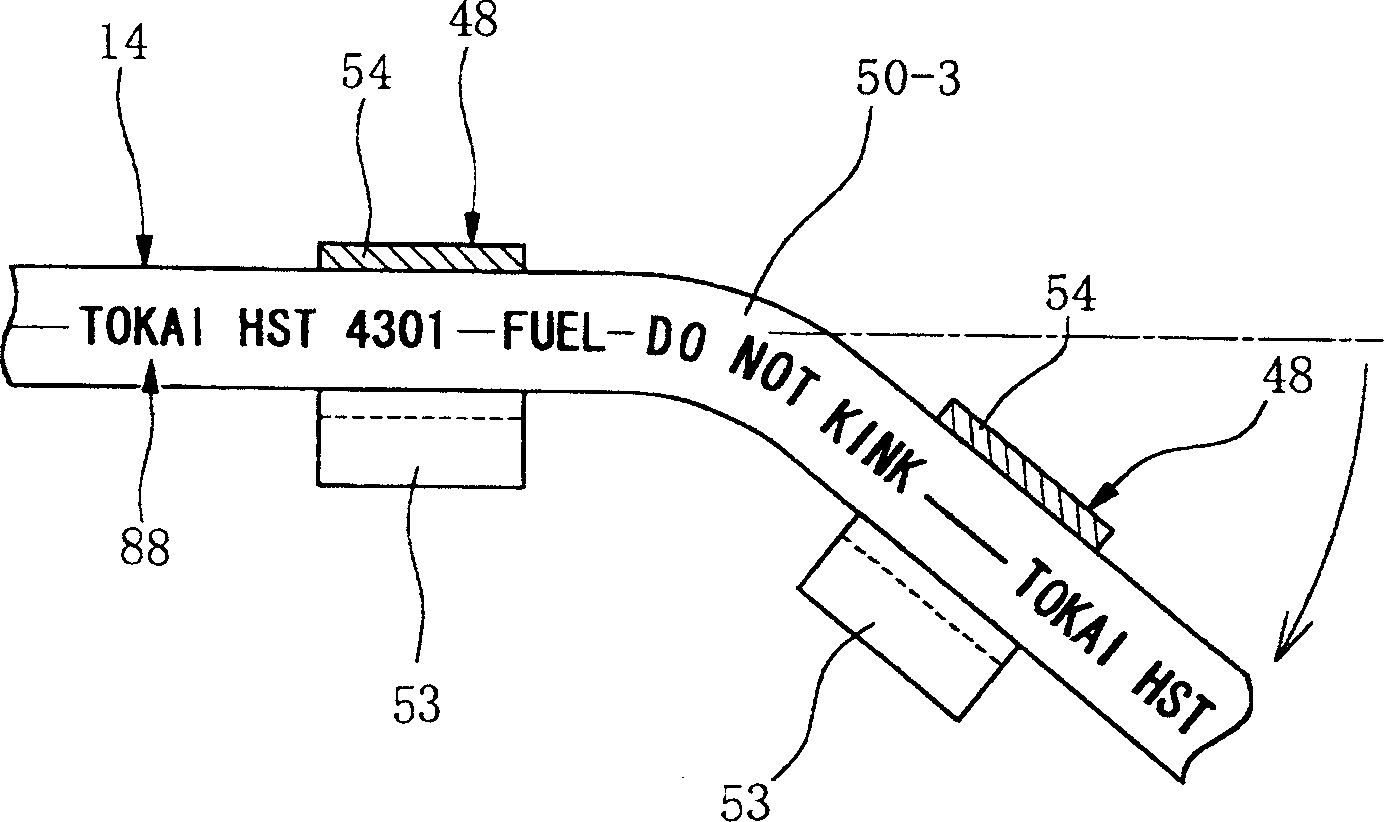

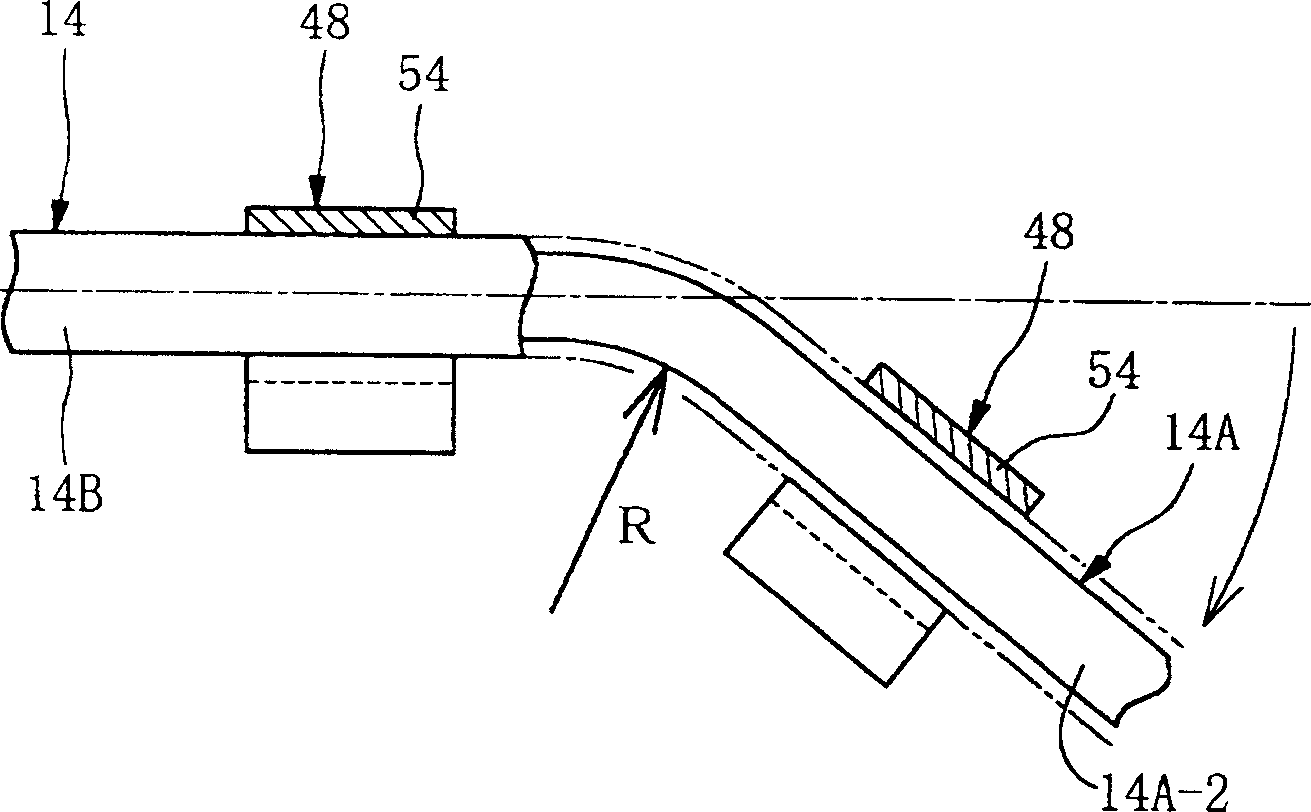

[0140] Fig. 4 shows the state of the connector-equipped resin pipe between the engine and the fuel tank even before it is assembled in the body of the motor vehicle. In these figures, reference numeral 14 denotes a resin tube, and reference numeral 16 denotes a connector (quick connector). These connectors 16 , 16 are mounted on both ends of the resin pipe 14 . However, when the resin tube 14 is directly connected to a fitting member such as the fitting pipe 10 on one end of the resin tube by press fitting or the like, the connector 16 is only mounted on the other end of the resin tube 14 .

[0141]Here, the resin pipe 14 has a straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com