Gauge shape-changing apparatus and method for changing shape quickly by utilizing shared standard screen and shared inner panel

A technology of inner panels and standard screens, applied in glass forming, glass pressing, glass manufacturing equipment, etc., can solve problems such as unsatisfactory effects, thermal sensors in different positions, and complicated adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

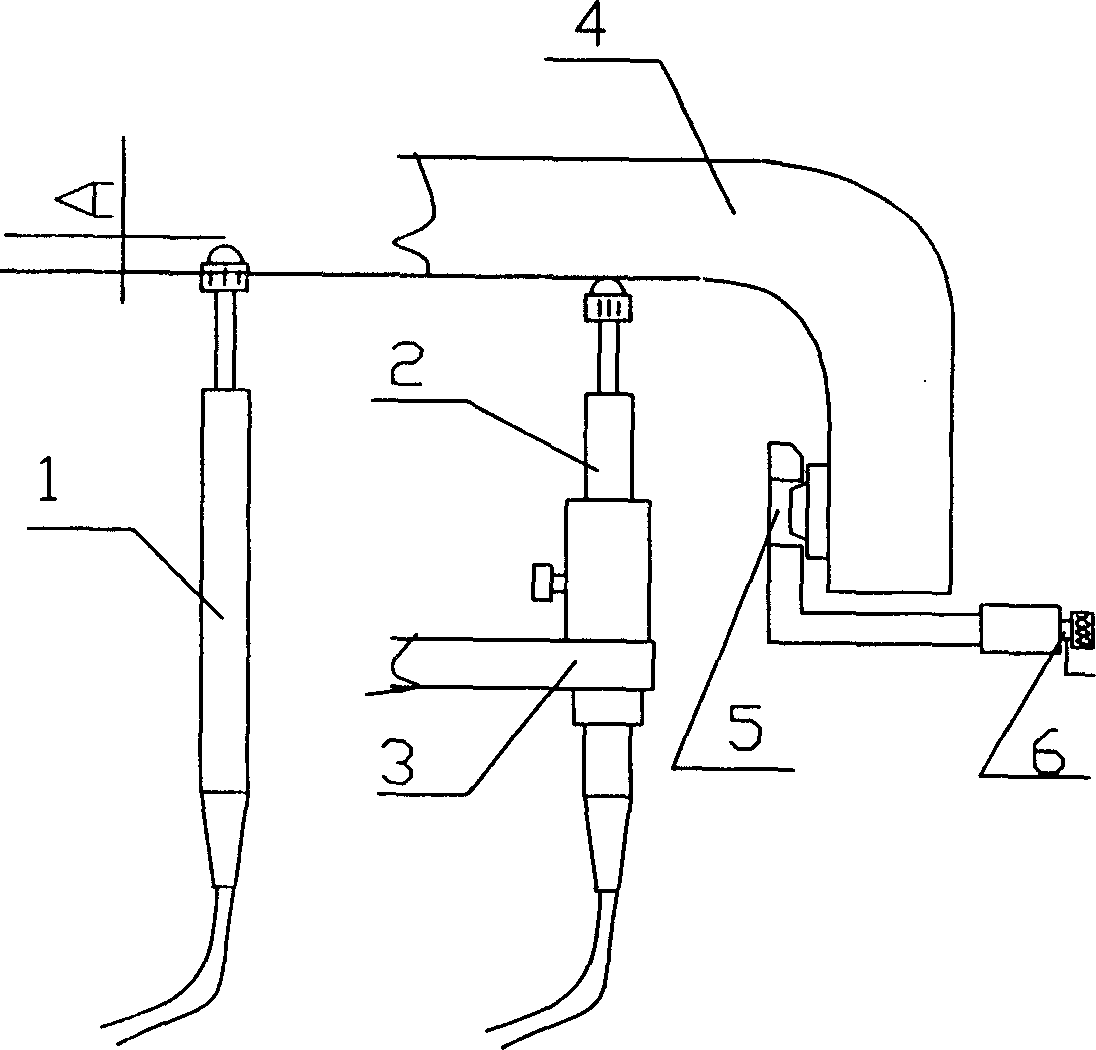

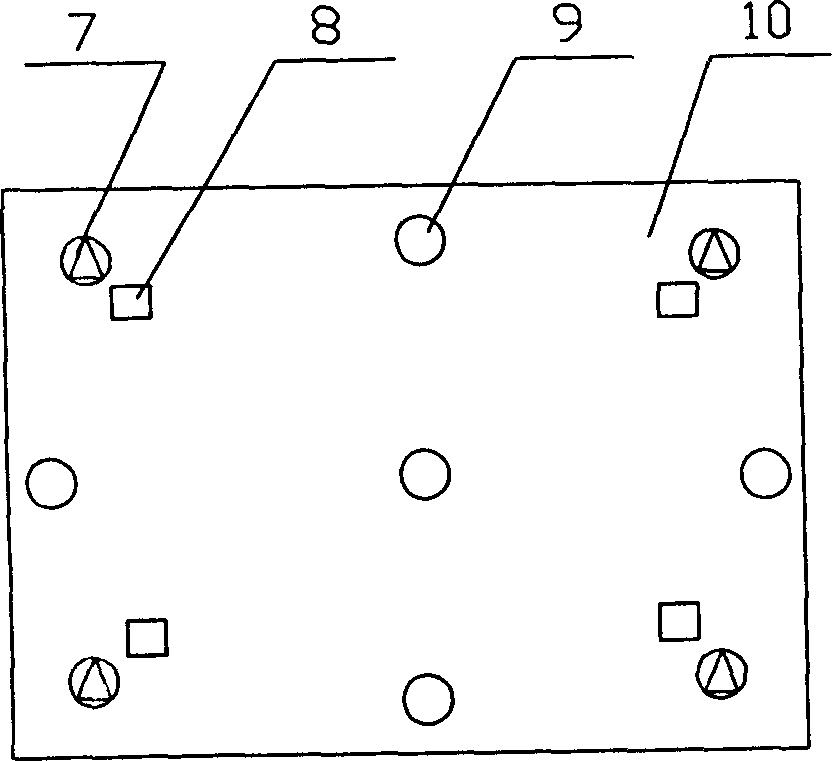

[0022] see figure 1 and figure 2 ,exist figure 1 Among them, 1 is the state of the sensor when the glass screen is not being measured, 2 is the state of the sensor on the inner panel when the glass screen is being measured, 3 is the inner panel, 4 is the glass screen to be measured, and 5 is for the pin on the gauge Pin clamping hole, 6 is the adjustment cylinder; figure 2 Among them, 7 is the thermal sensor position of Hitachi 21″ and Toshiba 21″ C6~C9, and there are four holes with “△” in the indicated circle; 8 is the thermal sensor position of Samsung 21″C6~C9, and the indicated “□” There are four holes in ", 9 is Hitachi 21", Toshiba 21", and Samsung 21", three types of thermal sensors C1 ~ C5 positions, indicating a total of 5 round holes, 10 is the inner surface measurement board, A is the glass screen in the The amount that is compressed when a gauge measures.

[0023] A gauge changing device that utilizes a shared standard screen and a shared inner panel for rap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap