Unit for determining broken end position of weaving machine

A technology for determining device and warp breaking, applied in looms, weaving, textiles and papermaking, etc., can solve problems such as difficult to find the position of warp breaking, and achieve the effect of improving weaving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

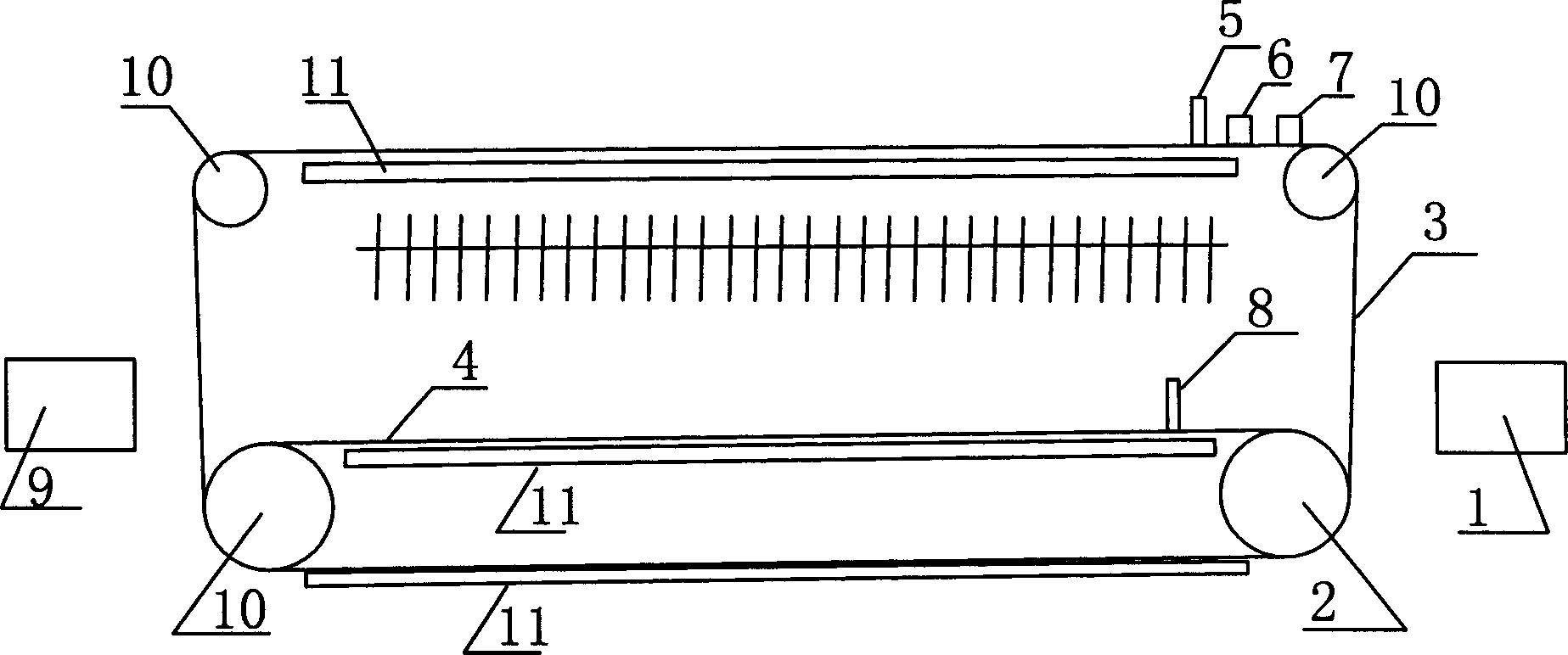

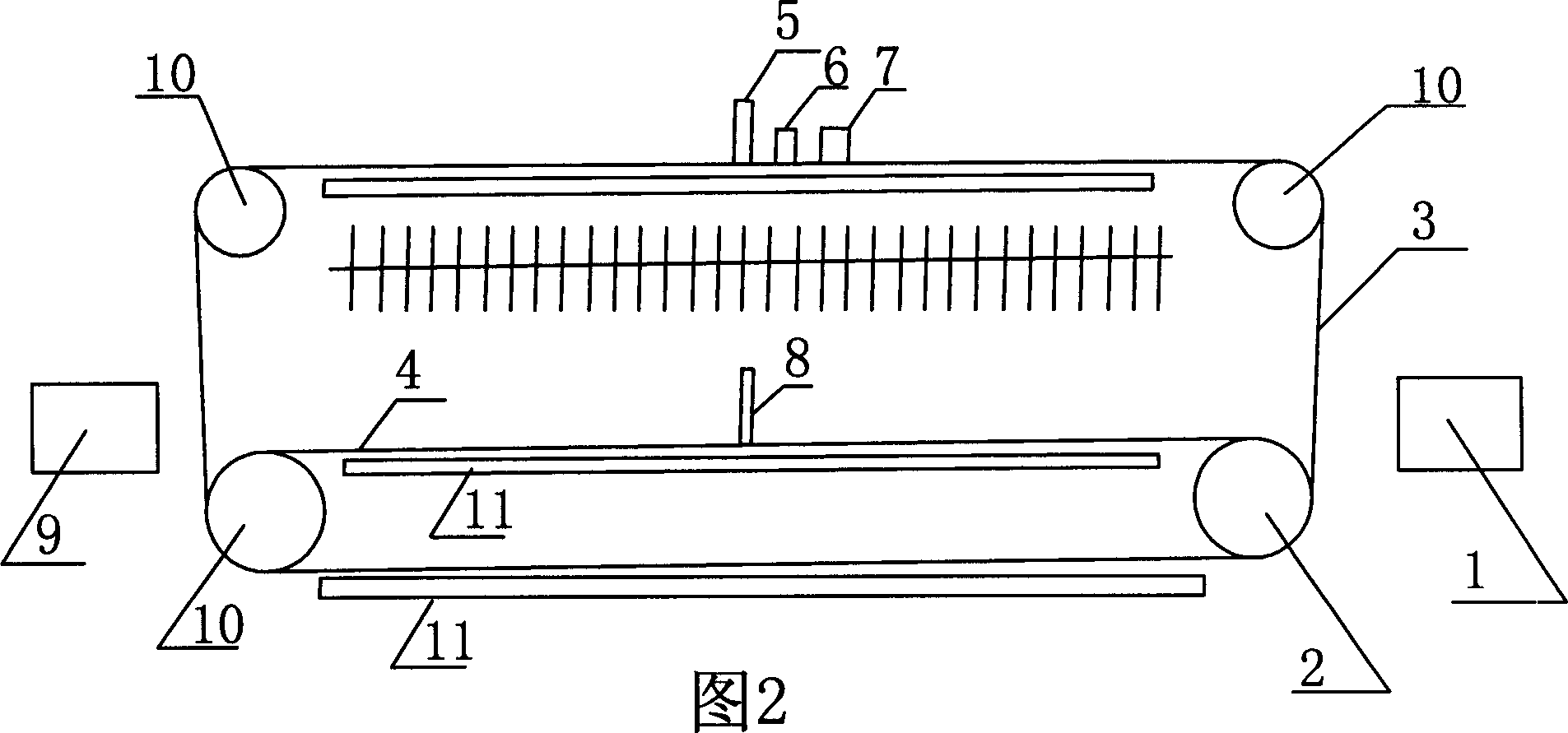

[0008] Loom warp breaking position determining device such as figure 1 As shown, it consists of distribution box 1, small motor 2, toothed belt A3, toothed belt B4, indicator light 5, switch button 6, contact sensor A7, contact sensor B8, photoelectric sensor 9, guide roller 10, guide rail 11 . Among them, the small motor 2, the indicator light 5, the switch button 6, the contact sensor A7, the contact sensor B8, and the photoelectric sensor 9 are all connected to the distribution box 1 by wires; the indicator light 5, the switch button 6, and the contact sensor A7 are all in the gear On the belt A3, the position is as shown in the figure; the contact sensor B8 is on the toothed belt B4. The 2 wheels of the small motor are toothed wheels, and the toothed belt A3 and the toothed belt B4 are non-extensible plastic belts. The toothed belt A3 and the toothed belt B4 bypass the guide roller 10 and run on the guide rail 11, and the distance between the contact sensor B8 and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com