Reciprocating high-temperature high-load friction wear test method and apparatus

A friction and wear test, reciprocating technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of short lifespan of the lower sample fixture, low test temperature, large friction, etc., to achieve accurate load application, improve The effect of improving the carrying capacity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

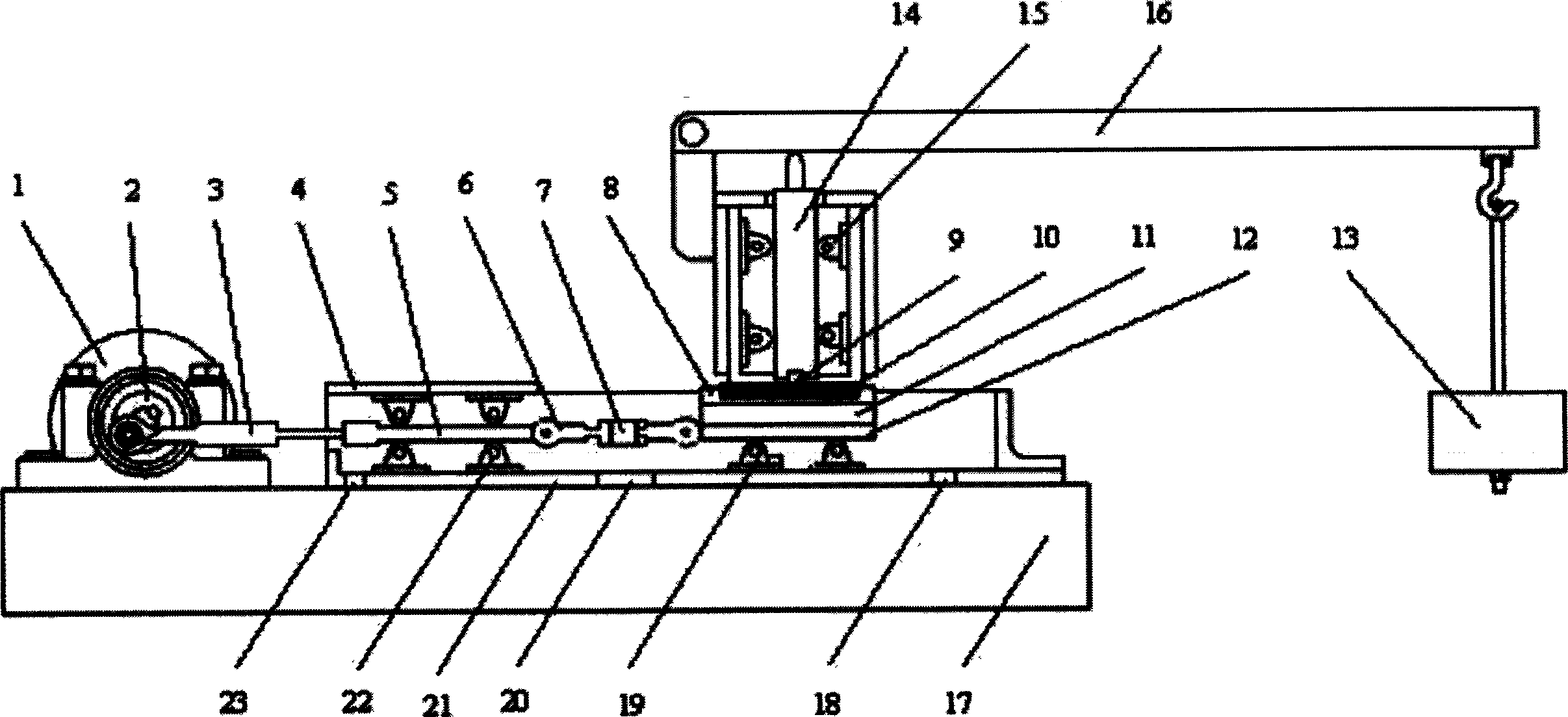

[0016] 1. Install the lower sample 10 of 10mm×8mm×100mm into the lower sample holder 8 .

[0017] 2. Install the upper sample 9 of 15mm×10mm×10mm into the upper sample holder 14 .

[0018] 3. Lift the lever 16, and load the fixture 14 installed on the upper sample from above until it contacts the lower sample.

[0019] 4. Put down the lever 16, select a weight 13 with a quality of 200N, and hang it on the force end of the lever 16.

[0020] 5. The ratio of the lever is 7:1, and the load applied between the upper and lower samples at this time is 1400N.

[0021] 6. Turn on the 220V power supply, the heater 11 starts heating, and at the same time turn on the power supply of the oil pump, the lubricating and cooling oil is injected through the holes 18 and 23, and flows out through the hole 20 for circulation. Set the heating temperature to 150°C, and the flow rate of the oil pump to 2 liters per minute.

[0022] 7. Turn on the power, the motor drives the eccentric shaft 2 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com