Shear wall hidden with vertical soft steel energy consupting band and mfg. method thereof

A shear wall and soft steel technology, applied to walls, building components, and earthquake resistance, can solve problems such as the consumption of earthquake energy, and achieve the effects of high lead energy consumption, easy replacement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

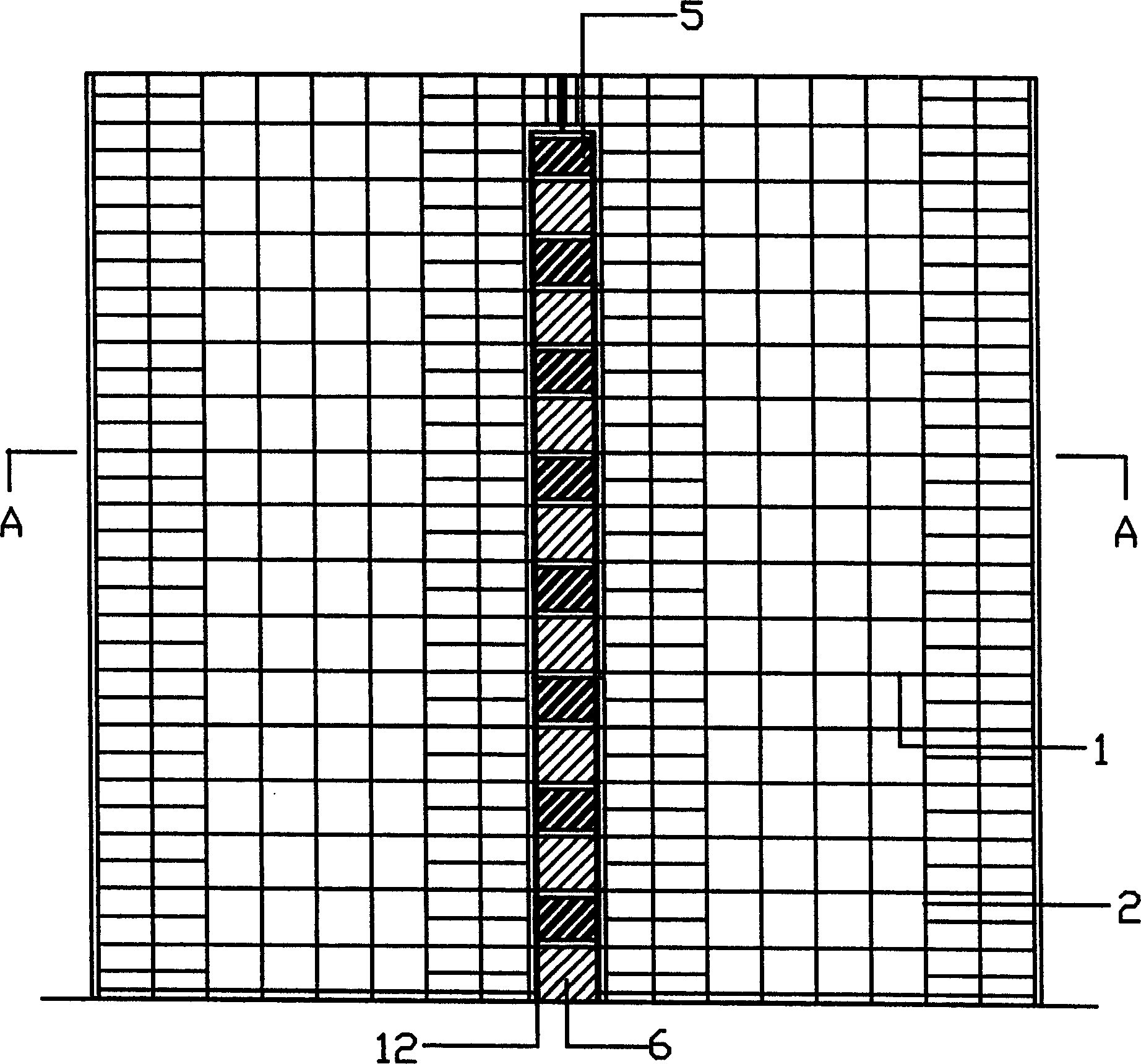

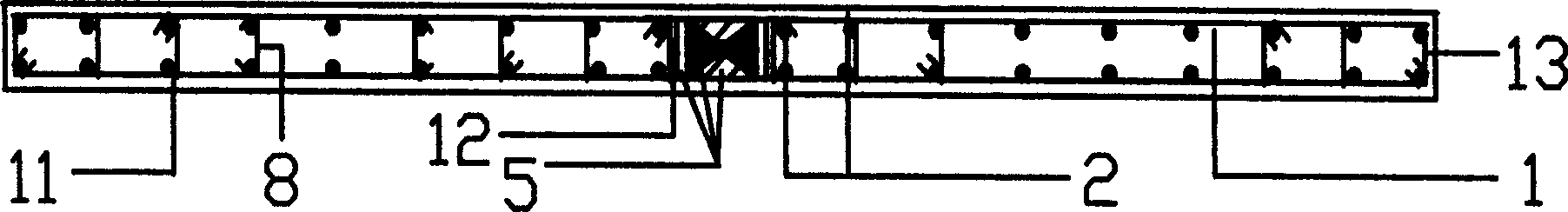

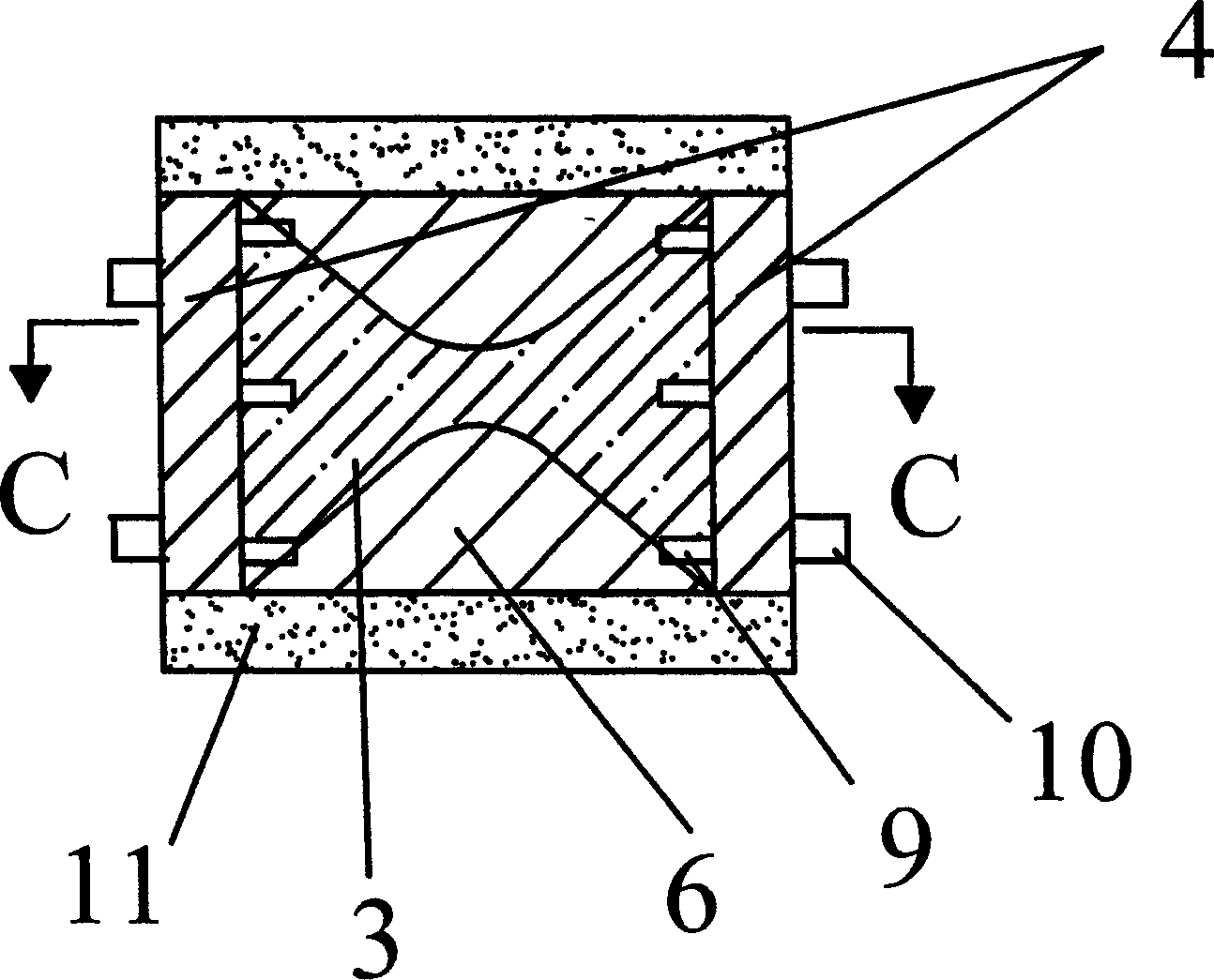

[0032] Attached below figure 1 ~ attached Figure 4 The embodiment of the present invention is described in further detail:

[0033] The built-in vertical soft steel energy-dissipating belt shear wall is composed of vertical slot shear wall and X-shaped damper 5, and its structure diagram is as follows figure 1 , figure 2 As shown, the composition structure of the X-shaped damper 5 and its configuration method in the shear wall are as follows image 3 , Figure 4shown. A vertical joint is set in the middle of the shear wall, the vertical distance between the upper end of the vertical joint and the top of the shear wall is 1 to 2 times the thickness of the shear wall section, and the lower end of the vertical joint is connected to the foundation. When configuring the structural reinforcement of the shear wall, the shear wall limbs on both sides of the vertical joint are used as independent shear wall reinforcement, so as to ensure that each part of the shear wall can work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com