Releasing gadget sealing insertion head gas-injection tube pile

A gas injection pipe and hand-throwing technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of high application cost, polluted oil layers, hidden safety hazards, etc., and achieves simple operation procedures, prevention of oil layer pollution, The effect of work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

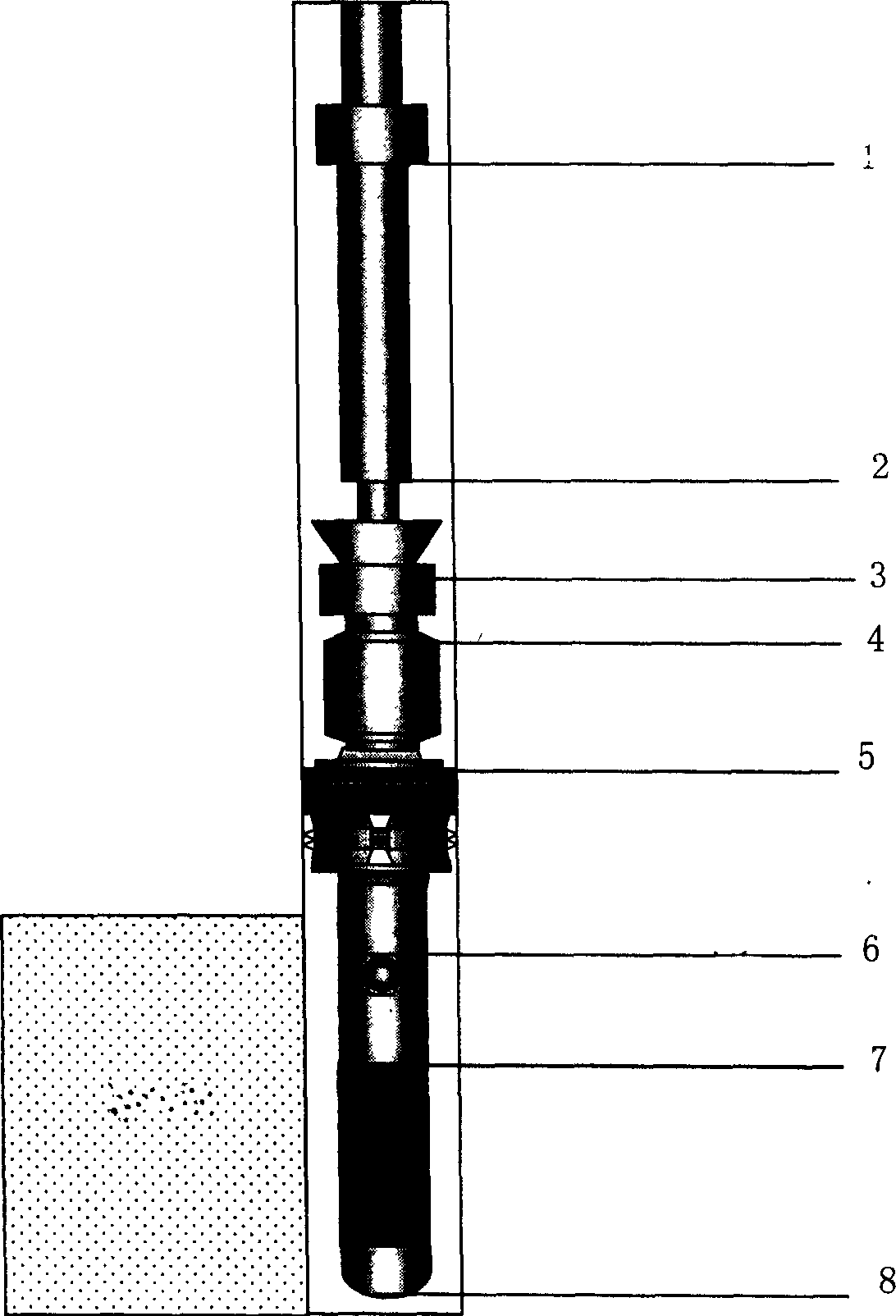

[0014] refer to Figure 1-Figure 3 , a tracheal injection string with hands-off tight insertion, including a mandrel 1, a packer 5, a constant pressure ball valve 6, a screen pipe 7 and a plug 8, and also includes the lower end of the mandrel 1 and the upper end of the packer 5 in sequence The connected sealing plug 2, the throw-back sleeve 3 and the disc valve controller 4, and the lower end of the packer 5 are connected with a constant pressure ball valve 6, a screen pipe 7 and a plug 8 in sequence.

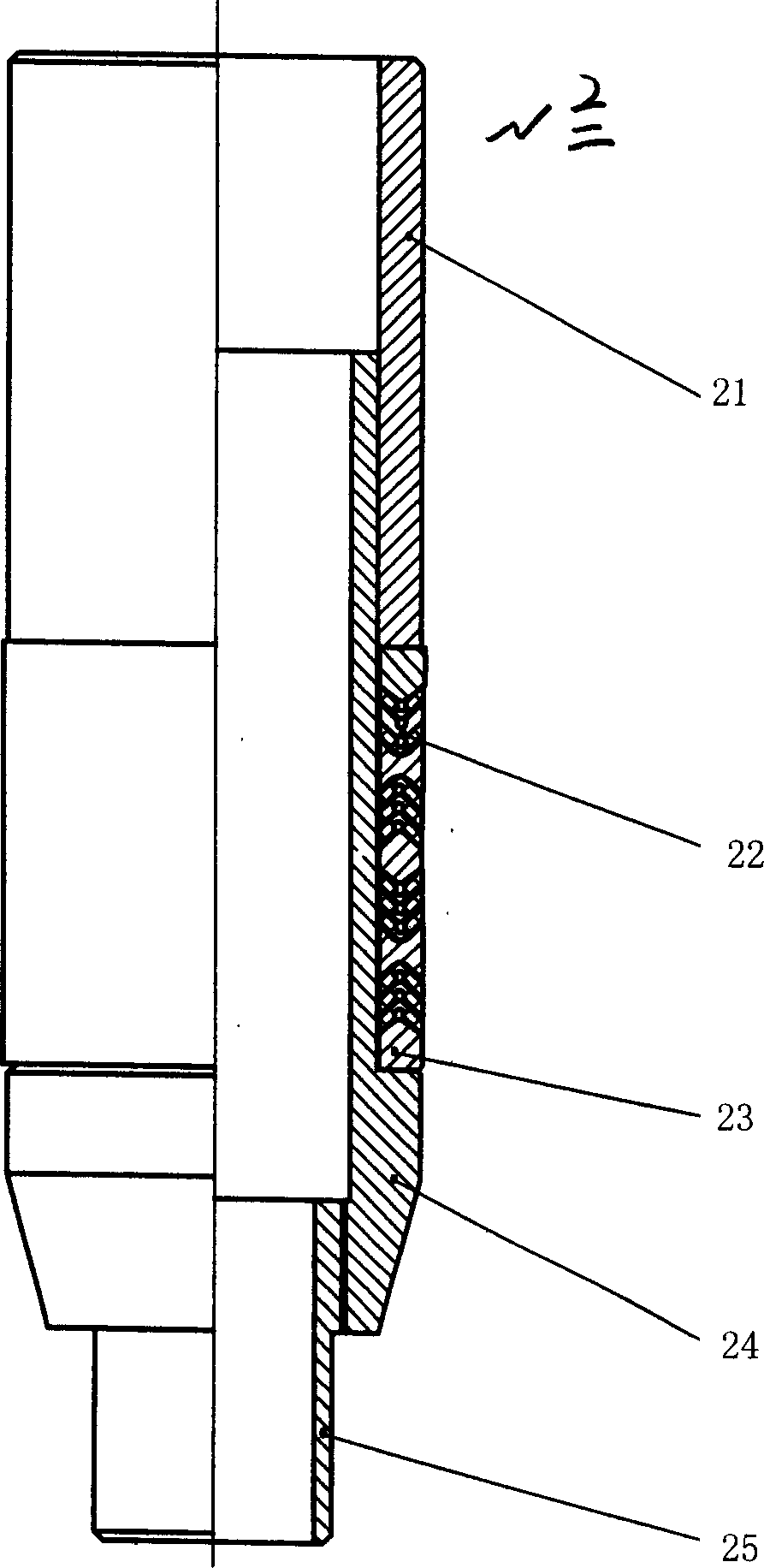

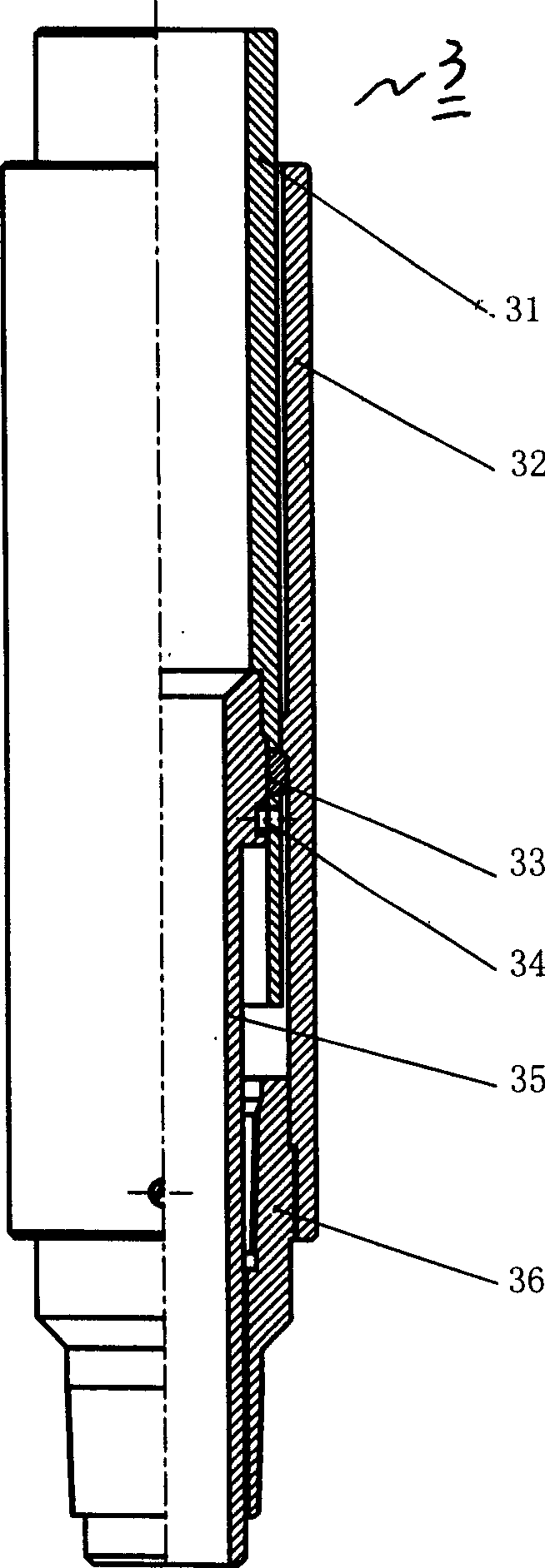

[0015] The sealing plug 2 includes a sealing seat 24 and a retaining ring 23 installed thereon, a sealing body 22 and an upper joint 21 , and a close-fitting guide rod 25 connected to the other end. The disc valve controller 4 includes a connecting sleeve 49 and a sealing joint 410 connected to its lower end, a valve seat 42 installed in the upper end, an "L" shaped sealing body 44 and an upper joint 41, and a disc valve plate 46 installed on the valve seat 42 And torsion spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com