Anti loosening nut

A nut and anti-disassembly technology, which is applied to nuts, bolts, threaded fasteners, etc., can solve problems such as installation difficulties, anti-disassembly nuts cannot be disassembled, and increase product costs, and achieves simple installation process, easy implementation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

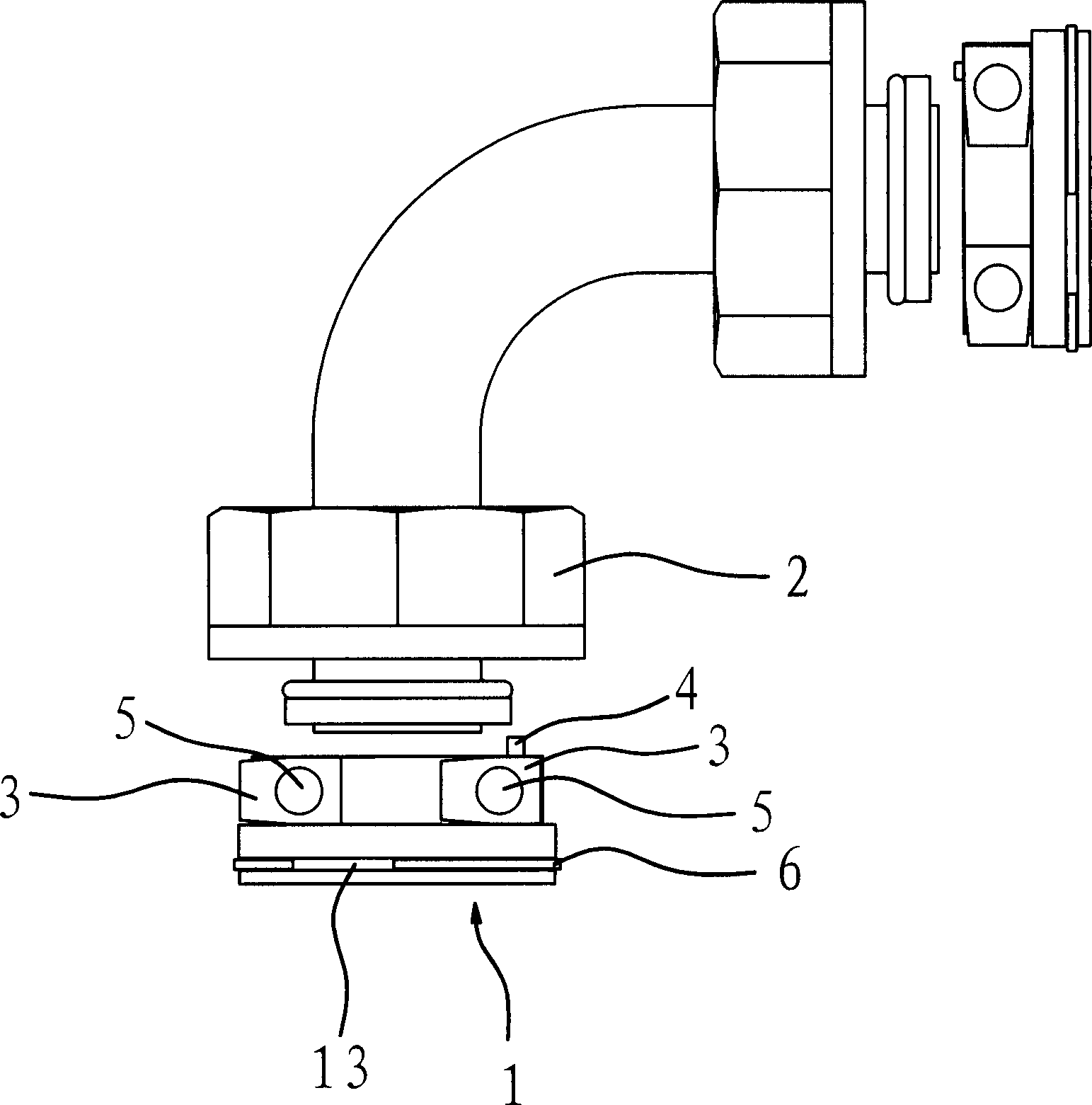

[0022] Such as figure 1 As shown, the anti-dismounting nut is installed on the gas pipeline, and the gas meter is connected with the gas pipeline by it.

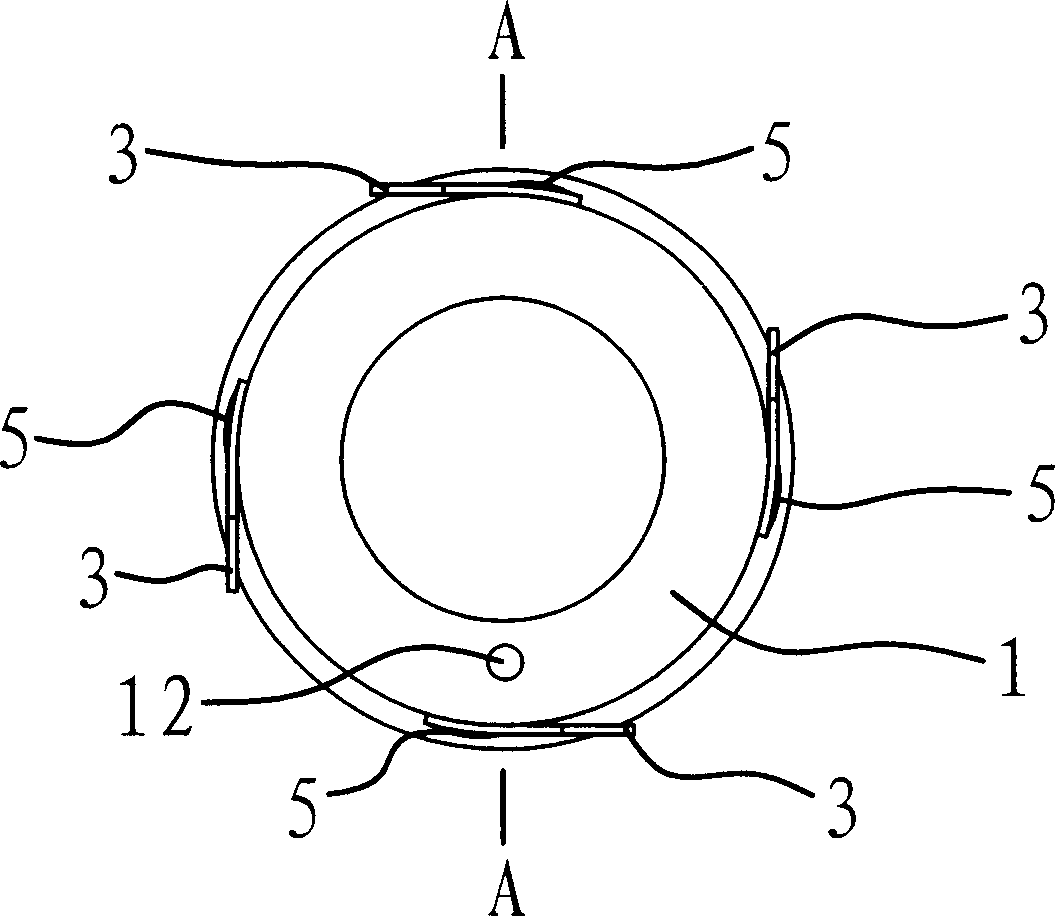

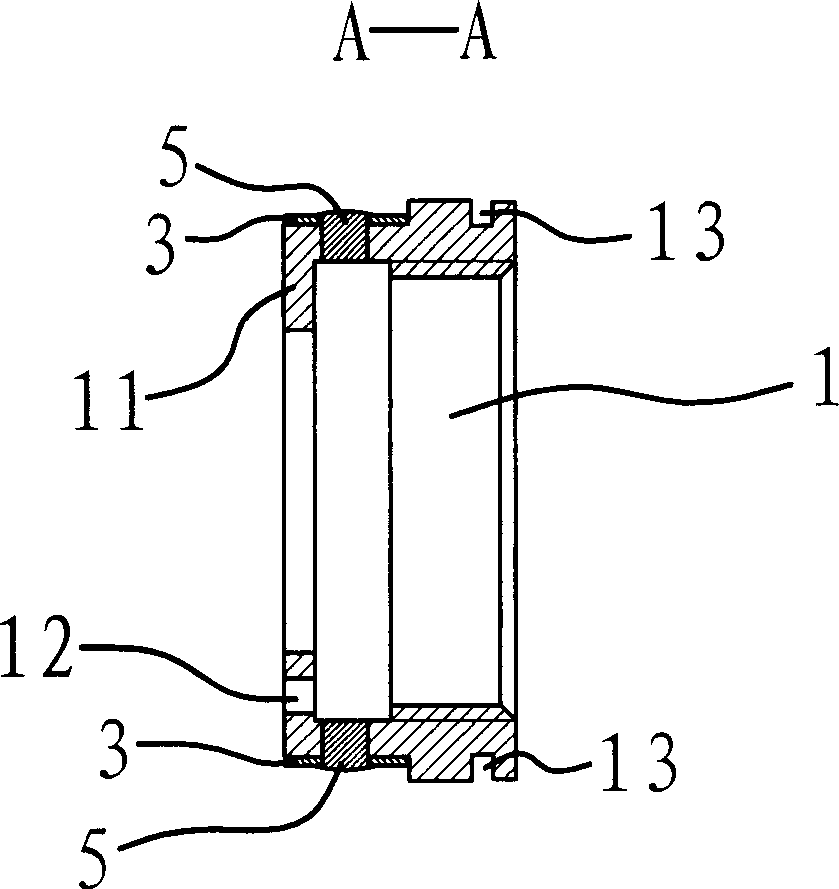

[0023] The anti-unloading nut includes an inner core 1 and an outer shell 2, and the outer shell 2 is sleeved on the outer side of the inner core 1. Such as figure 2 As shown, the inner surface of the inner core 1 has threads, and the inner core 1 is screwed to the interface of the gas meter through the threads. The outer surface of the inner core 1 is fixedly connected with four evenly distributed elastic sheets 3. In this embodiment, the fixed pin 4 passes through one end of the elastic sheet 3 to be fixedly connected to the inner core 1. See image 3 shown. The other end of the elastic sheet 3 extends outward.

[0024] Such as Figure 4 and Figure 5 As shown, the inner surface of the housing 2 is provided with seven evenly distributed slopes 22 . Slope 22 is made up of straight face 221 and slope 222, sees Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com