Gas concentration detection method and equipment based on optical fiber laser intracavity sensitivity

A gas concentration detection, fiber laser technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of unfavorable sensor integration and packaging, and achieve the effect of being suitable for distributed solutions, improving measurement accuracy, and enhancing the ability of long-distance transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Taking the detection of carbon dioxide concentration as an example, the spectral absorption peak position of carbon dioxide gas in the optical communication band is selected to be 1538 nanometers, and two fiber Bragg gratings with a reflection peak position of 1538 nanometers and a reflectivity of 99% are designed and fabricated.

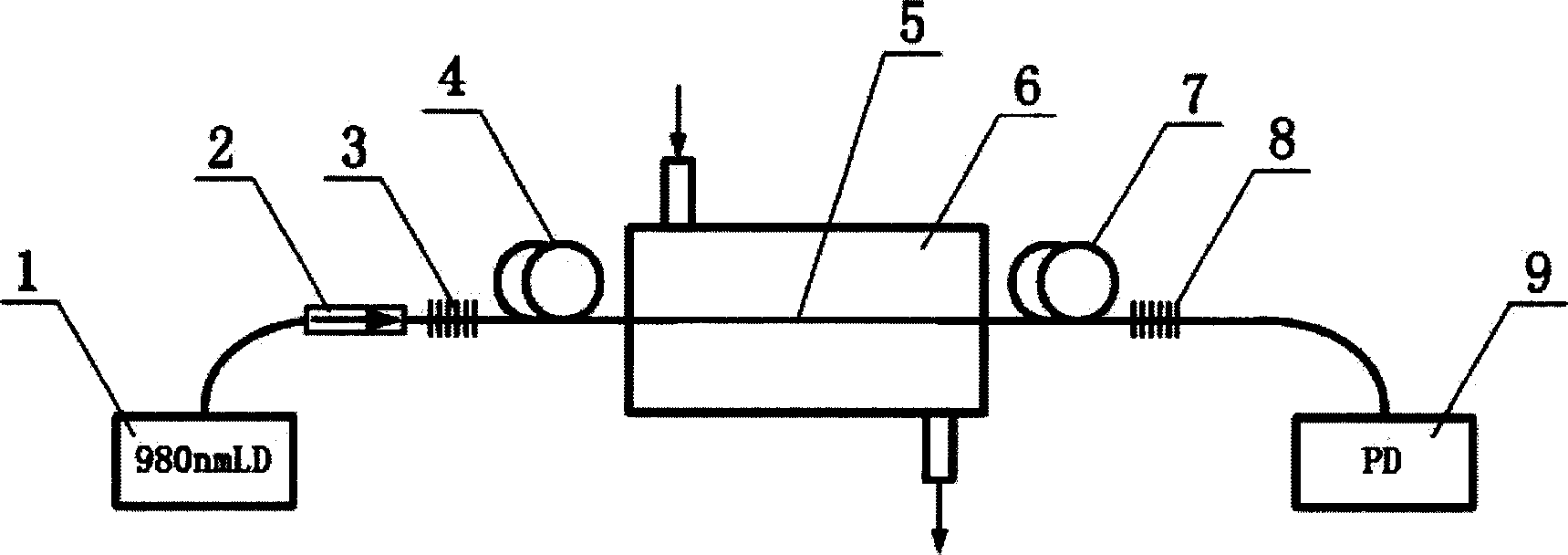

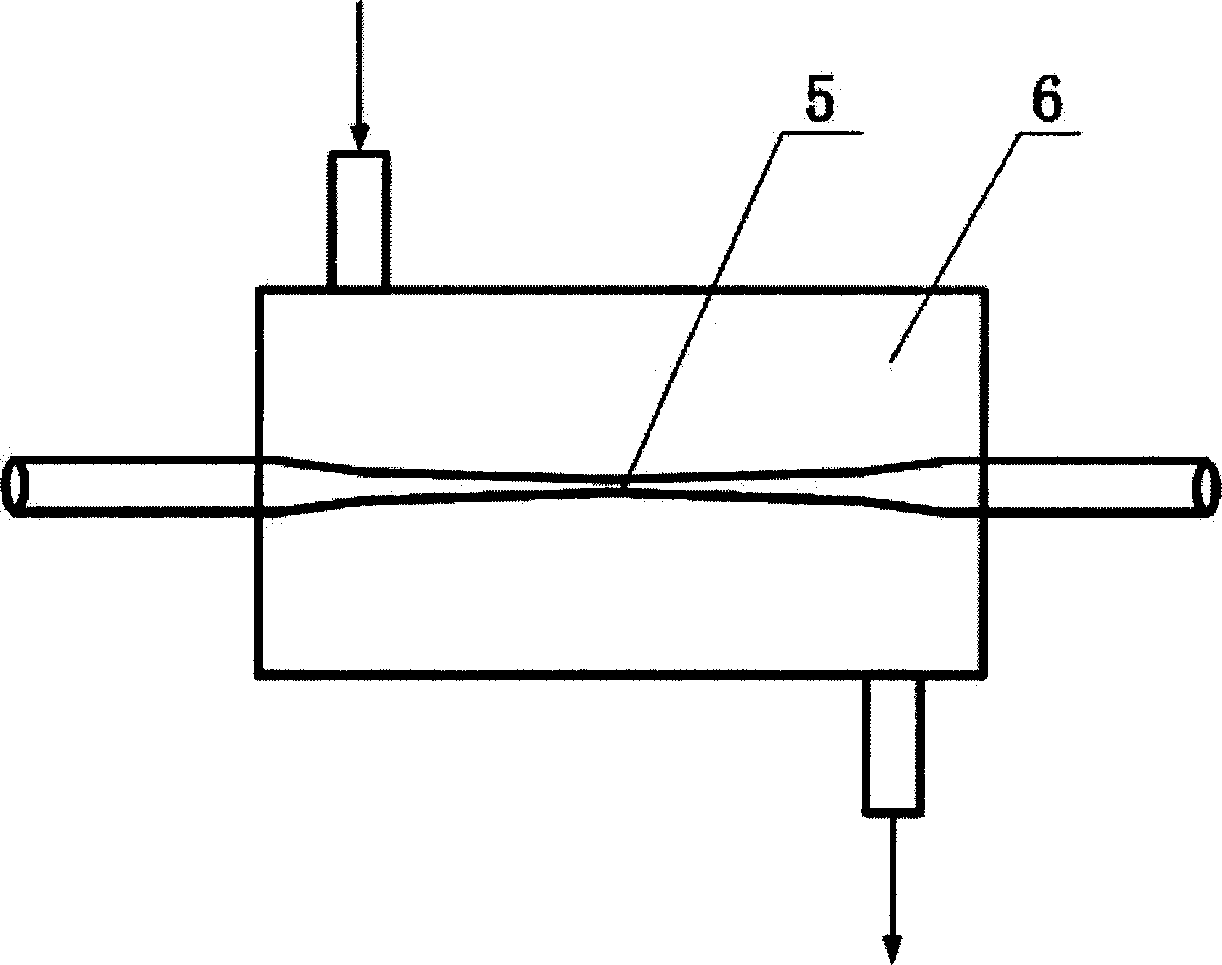

[0020] Such as figure 1 with 2 As shown, one is placed in the air chamber 6 and has a diameter of 2 microns and a length of 10 centimeters. The two ends of the tapered fiber 5 are respectively optically connected with the erbium-doped optical fiber 4 and 7. The erbium-doped optical fiber 4 and 7 The other end is respectively equipped with a fiber Bragg grating 3 and a pumping source 1 with a wavelength of 8,980 nm optically connected to a fiber Bragg grating 3 through a one-way isolator 2, and a photodiode 9 is optically connected to another fiber Bragg grating 8.

[0021] The DFB laser with a wavelength of 980 nm works, and the linear cavit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com