Vertical cavity surface-emitting laser and preparation method thereof

A vertical cavity surface emission, laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of difficult to meet the application requirements of narrow linewidth of lasers, affecting the performance and stability of laser devices, and large spectral linewidth, etc. Achieve the effect of improving device performance and reliability, increasing the effective cavity length, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

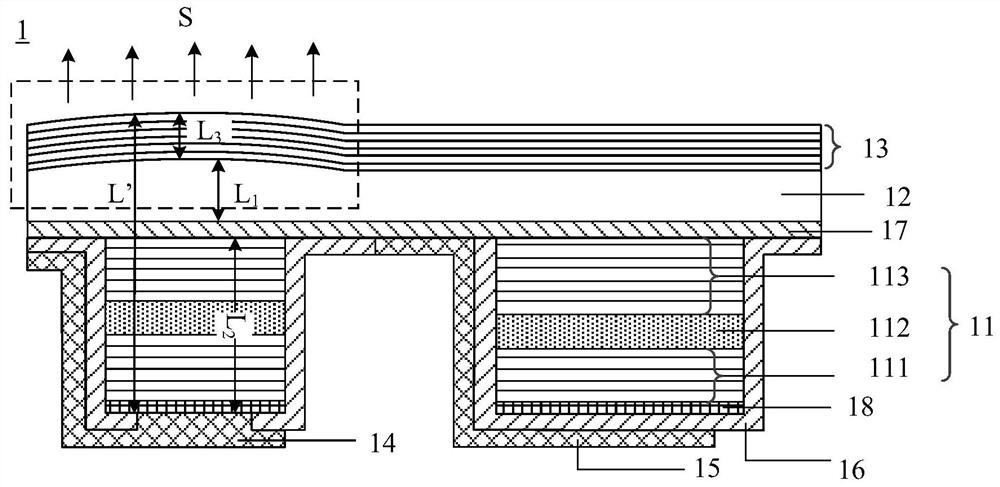

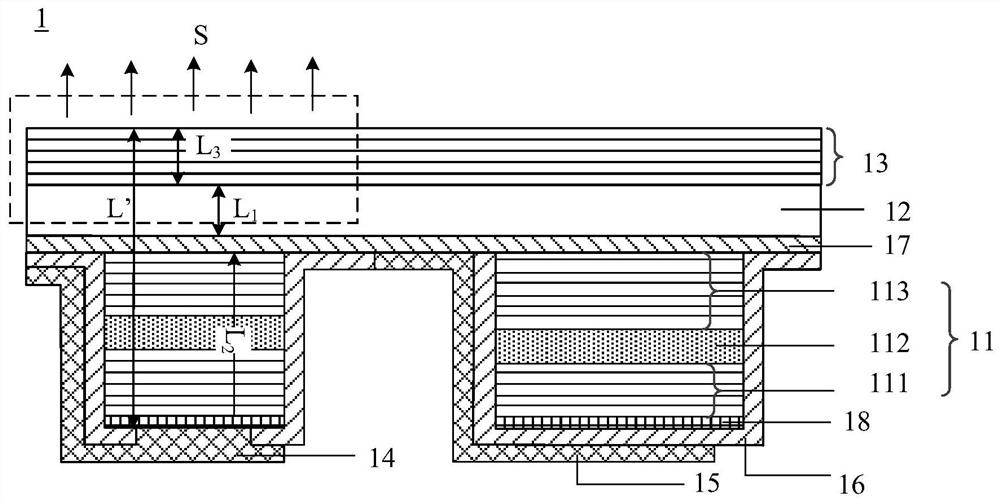

[0029] An embodiment of the present invention provides a vertical cavity surface emitting laser. figure 1 A schematic cross-sectional structure diagram of a vertical cavity surface emitting laser provided by an embodiment of the present invention. Such as figure 1 As shown, the vertical cavity surface emitting laser comprises a laser resonator structure 1; the laser resonator structure 1 comprises a laser cavity 11, a substrate 12 and an external cavity resonator 13 arranged in layers; along the outgoing direction of the laser beam (such as figure 1 shown in the S direction), the effective cavity length L' of the vertical cavity surface emitting laser includes the thickness L of the laser cavity 2 , the thickness of the substrate L 1 and the thickness L of the external cavity resonator 3 ; The outgoing direction of the laser beam is parallel to the direction in which the substrate 12 points to the external cavity resonator 13 .

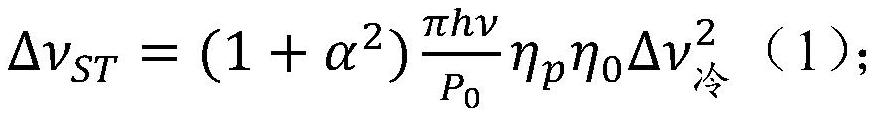

[0030] Exemplarily, the spectral line width...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com