Narrow-linewidth external cavity semiconductor laser linear array based on diffraction grating array

A diffraction grating and semiconductor technology, applied in semiconductor lasers, semiconductor laser optical devices, lasers, etc., can solve the problems of increased optical components, low output power, complex optical path adjustment, etc., to improve device stability and reduce spectral line width. , The effect of simplifying the optical path structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

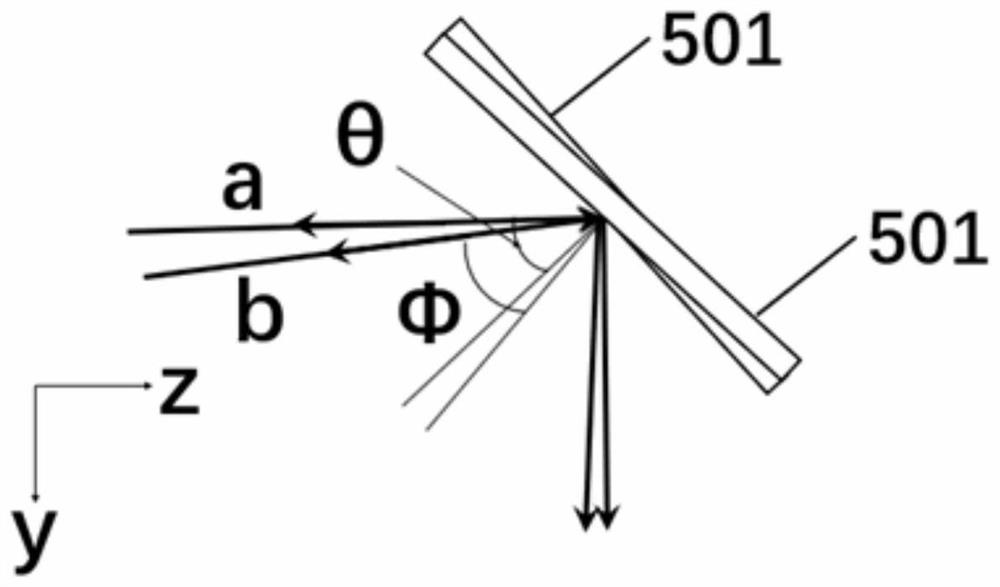

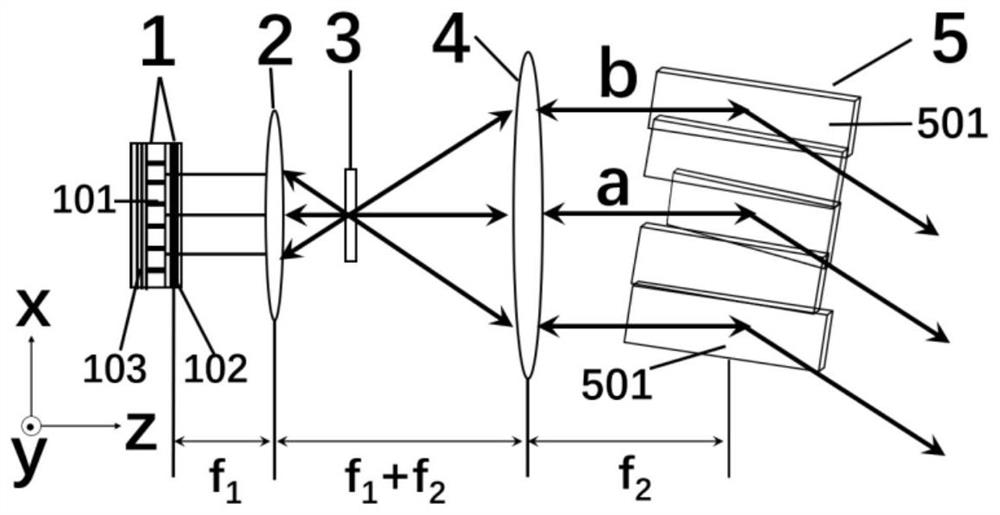

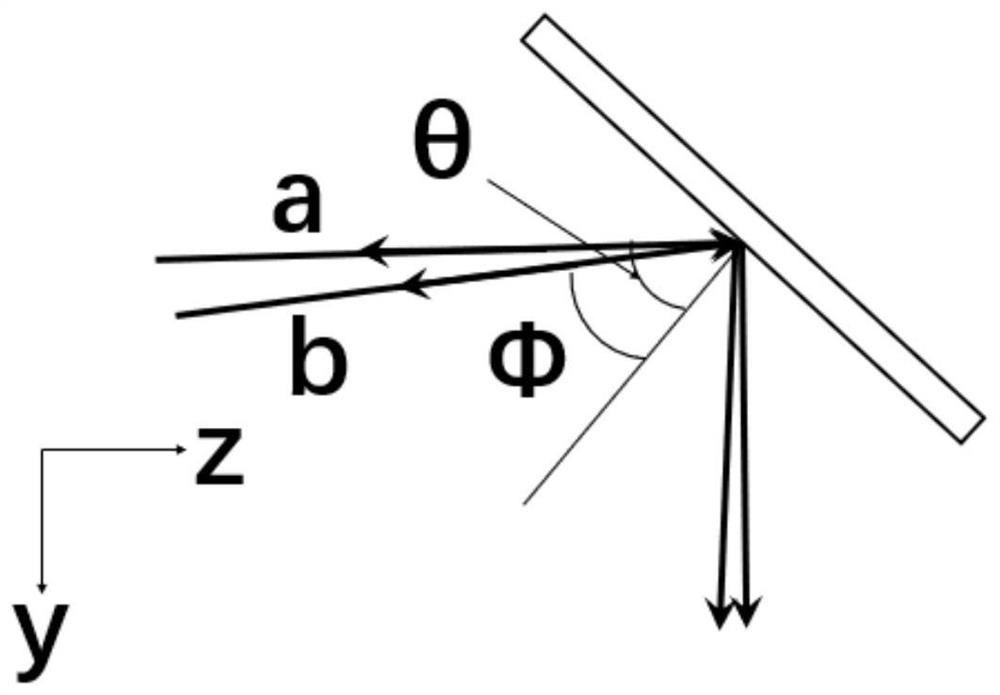

[0020] Such as figure 2 , image 3 , Figure 4 As shown, the narrow-linewidth external-cavity semiconductor laser bar array based on the diffraction grating array includes a semiconductor laser bar array 1, and the semiconductor laser bar array 1 is composed of a gain waveguide 101, a fast-axis collimator mirror 102 and a waveguide grating 103, A small lens 2, a half-wave plate 3, a large lens 4, and a diffraction grating array 5 are sequentially arranged along the laser output direction of the semiconductor laser line array, and the distance between the small lens 2 and the semiconductor laser line array 1 is the focal length f1 of the small lens 2 , the small lens 2 and the large lens 4 are placed confocally to form an inverted telescopic system, which is used to compress the divergence angle of the slow axis in the x direction. If the magnification of the inverted telescopic system is n, the divergence angle of the slow axis will be compressed by n times. The distance fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com