Method for improving optical quality of optical grating external cavity laser

A technology of optical quality and lasers, which is applied in the field of optoelectronics and optics, can solve the problems of multiple lasing peaks, broadening of spectral linewidth, and degradation of optical quality of grating external cavity lasers, so as to reduce spectral linewidth and improve optical quality. The effect of quality and strong practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 (applied to Littrow optical path)

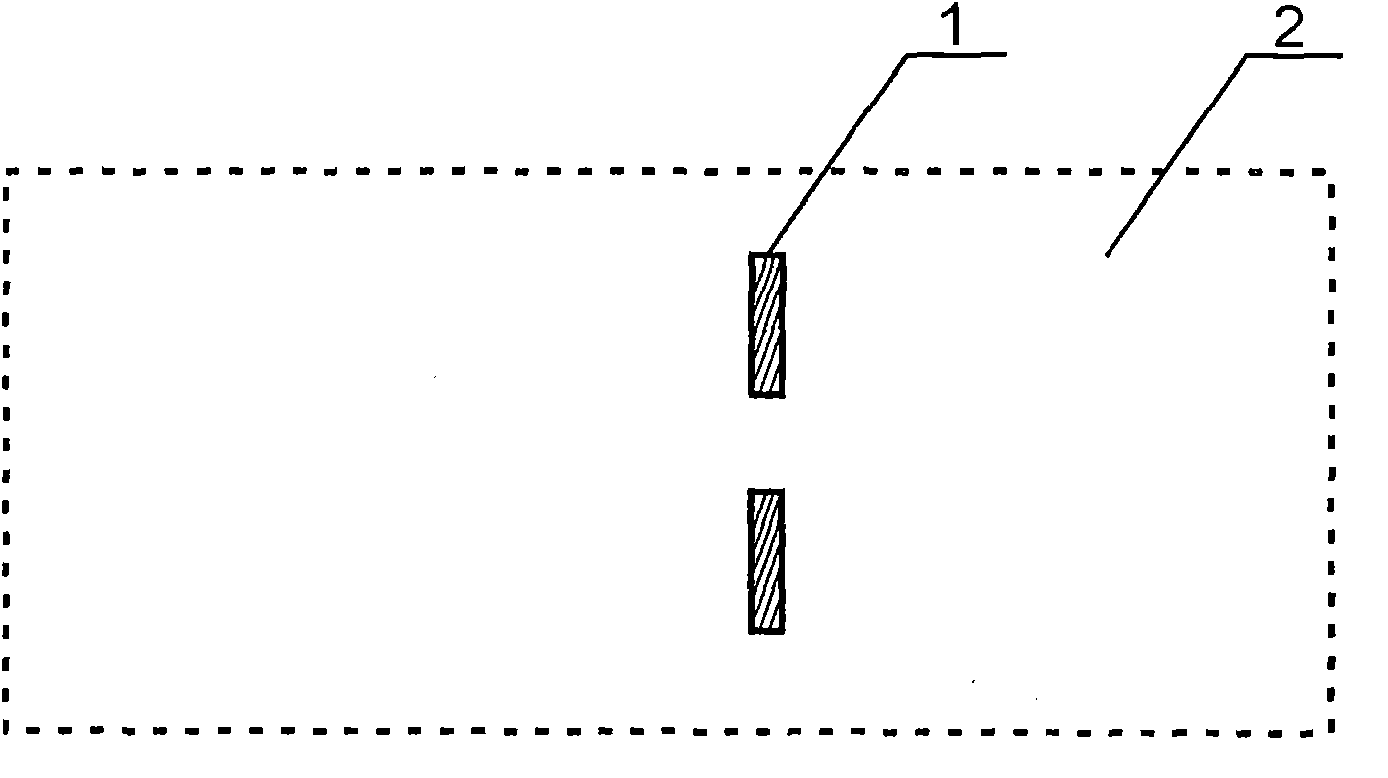

[0024] Please refer to figure 1 and image 3 .

[0025] The diaphragm 21 is installed in the optical path of the Littrow grating external cavity laser composed of the grating 22, the lens 23 and the gain device 24, by properly selecting the form of the diaphragm 21 and adjusting the size of the diaphragm 21 and its external The position in the optical path of the cavity can effectively reduce the spectral width of the output laser and improve its optical quality.

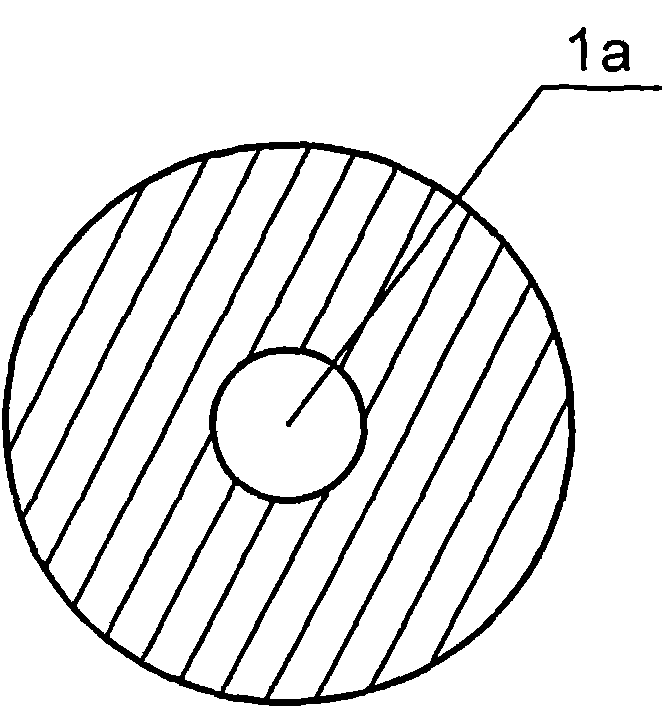

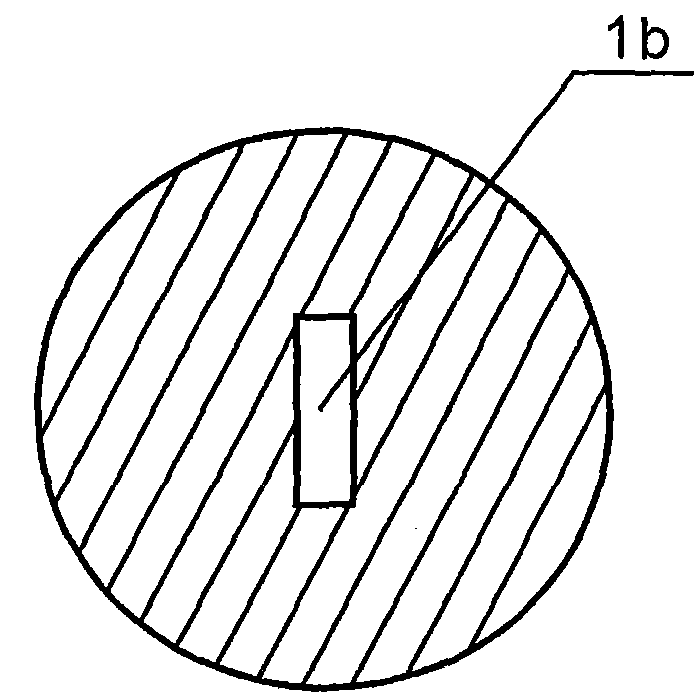

[0026] The above-mentioned aperture 21 can adopt (but not limited to) the form of a circle 1a and a rectangle 1b, and its size, such as the diameter of the circle 1a or the length and width of the rectangle 1b, can be appropriately selected according to actual needs.

Embodiment 2

[0027] Embodiment 2 (applied to Littman optical path)

[0028] Please refer to figure 1 and Figure 4 .

[0029] Diaphragm 31 is installed in the light path of Littman (Littman) grating external cavity laser that is made up of grating 32, reflecting mirror 33, lens 34, gain device 35, by selecting the form of diaphragm 31 appropriately and adjusting the form of diaphragm 31 The size and its position in the optical path of the external cavity can effectively reduce the spectral width of the output laser and improve its optical quality.

[0030] The above-mentioned aperture 31 can be in the form of (but not limited to) a circle 1a and a rectangle 1b, and its size, such as the diameter of the circle 1a or the length and width of the rectangle 1b, can be appropriately selected according to actual needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com